BIESSE’S CYBER-PHYSICAL ASSISTANCE SYSTEM

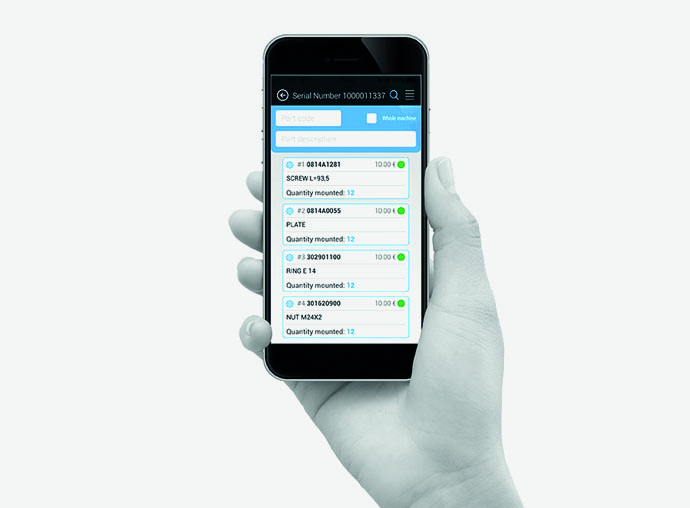

SOPHIA is the IoT platform created by Biesse in collaboration with Accenture which enables its customers to access a wide range of services to streamline and rationalise their work management processes.

The platform allows information and data to be sent in real time in relation to the technologies in use, optimising the performance and productivity of machines and systems.

The data collected enables the production process and machine functions to be analysed in detail, detecting malfunctions, assisting customers in maintenance operations, ordering replacement parts in less time and ultimately preventing faults.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil