#1 Return on Investment

Calculating a machine’s return on investment involves many possible variables, but the most important include immediate labour savings, additional business acquired through production capability/flexibility, the efficiency of the machine when it comes to repeatability and decreasing manufacturing defects. The elevated quality that comes with numerically controlled manufacturing is also a crucial consideration, as well as an affordable financing program.

When you reduce the repetitive labour required to produce a product, you can reallocate it to a more value-added task such as acquiring new business or expanding a product line. A CNC router spends most of its time working ‘alone’ with little to no supervision, making it the perfect choice for reallocating labour to maximise individual skills and capabilities.

#2 Product-Specific Configuration

You should also carefully consider what you want the machine to do. Specifying the application that drives the machine’s configuration. You should determine a well-defined set of parameters for the product you wish to create, write them down, and communicate the details of the application with the machine manufacturer. Doing so gives the CNC manufacturer boundaries to work within, ensuring that the machine you purchase can create the product your market demands. Some of these parameters might be minimum and maximum part sizes, the manufacturing method involved, such as nesting or cut-edge-drill, and material composition that leads to fittings and fixture alternatives.

Depending on the product-specific application requirements, there are also different approaches to increasing production, another important machine-configuration consideration! These methods usually involve levels of automation, ranging from relatively simple conveyors to complex systems that involve multiple robots and sorting stations. By making production requirements clear to your machinery manufacturer, you ensure they can be evaluated for feasibility from the start. Sometimes the evaluation can involve physical demos on similar machines or software simulations that reflect high-level accuracy to real-world implementation. The supplier’s product specialist should take responsibility for asking the right questions. The customer’s role is to provide a concise, realistic, end-product description which will act as the catalyst for the CNC manufacturer to request additional information as needed.

#3 Software

The basic point of a CNC is that it requires software to tell the machine where to go so that the results are repeatable and consistent from the first part produced to the last. Software, like the physical machine, must be able to create precisely what the end-user wants to produce. Different software companies have different levels of expertise in unlocking a machine’s manufacturing capabilities. The level of software capabilities should ideally be an exact match to the hardware capabilities of the machine.

Discover our award winning software.

#4 Workflow

Anyone looking to buy a CNC router should also evaluate how the new piece of equipment will interface with existing equipment and processes. These considerations can involve anything from material flow logistics on the floor, to how your current design software will program the new CNC.

#5 Maintenance

Maintenance considerations should include the manufacturer’s parts structure, their availability, and access to support, what type of support and how long it will be provided. Developments of modern CNCs reduce the need for a physical technician to be on site to provide the required maintenance. In fact, some machines do it automatically or offer customer collaboration to provide real-time machine care, translating to cost savings for the end user.

Make use of Biesse's full service support during these difficult times

Conclusion

Each of these five success factors shine a light on common questions that come up during the implementation process. In addition to doing your own research, don’t forget that professionals within the manufacturer’s organisation dedicate their careers to help you make an informed decision on your capital equipment. Use them for what they are – great, reliable, and easy to reach assets, always ready to discuss your application and how investing in a CNC will enhance productivity and quality now and in the future.

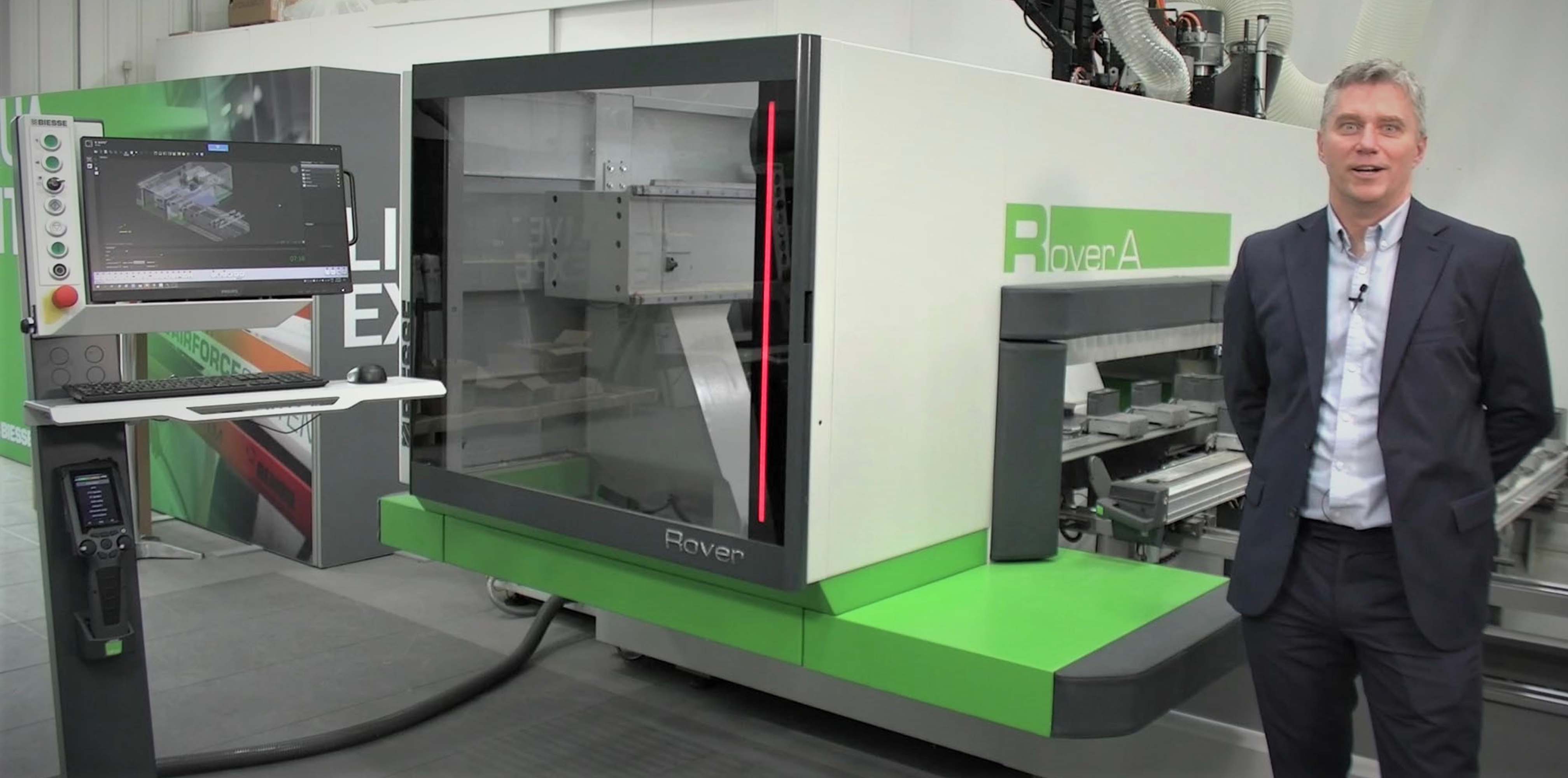

Review our full CNC router product range and submit an "ask for information" form to be contacted by a machine specialist as soon as possible.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil