Exceptional support from Biesse has helped Global Doors & Interiors grow its panel processing business and expand into new markets.

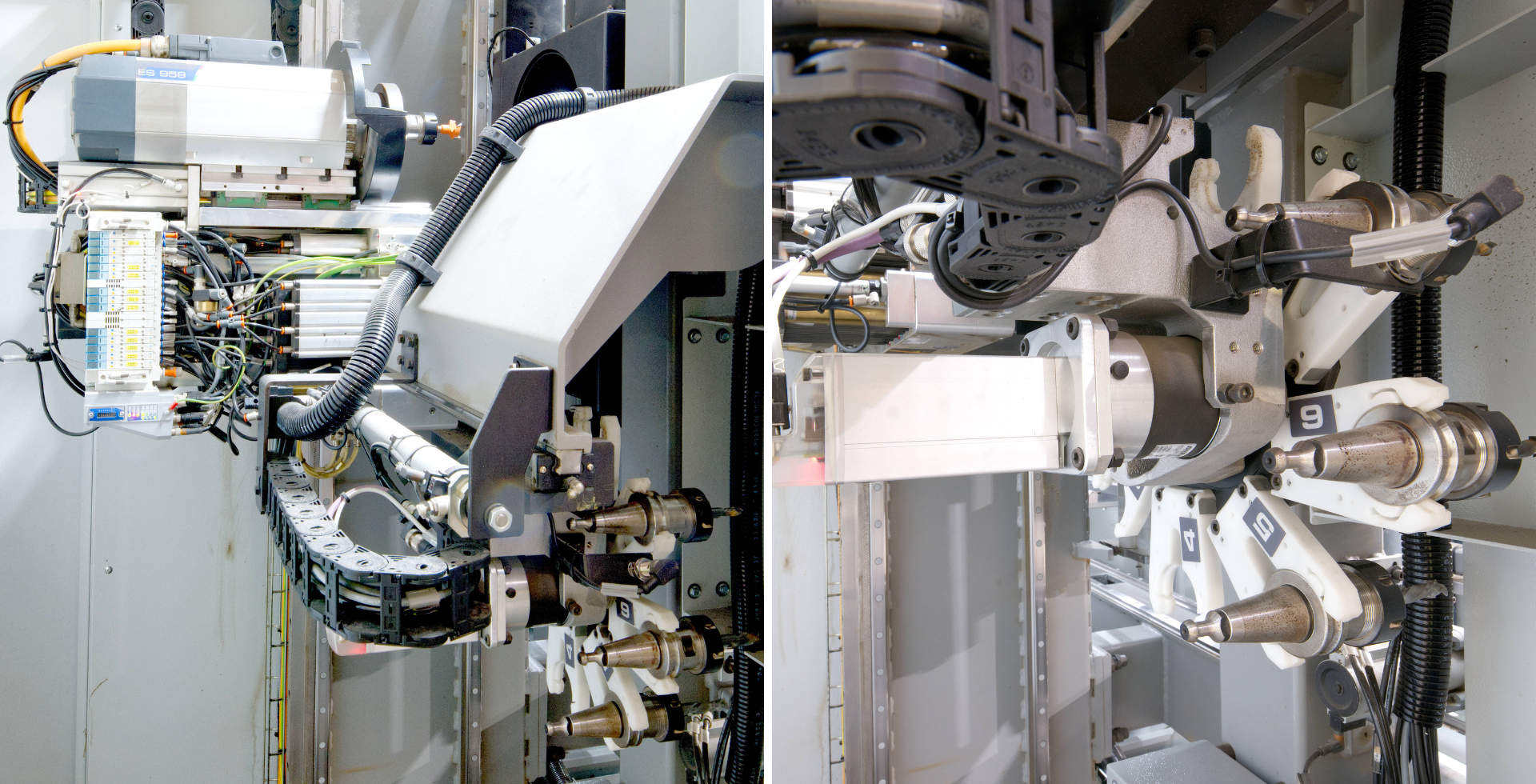

It was around seven years ago that Ossett based Global Doors & Interiors Ltd first bought into the Biesse brand with a Selco WN2 beam saw, a Brema Eko 2.1 drilling machine and an Akron 1300 edgebander.

Commercial Director Matthew Fletcher, Manufacturing Manager and Furniture Makers’ Company 60-for-60 winner, Tom Kaye and Commercial Manager Dan Farmer, have helped to restructure the company and set it on a course that would see the company developing new products and exploring new markets.

Matthew said that “When we were looking at machines, we went to all the major manufacturers but the thing that attracted me to Biesse were the care plans they offered. They are quite comprehensive and provide cover for five years. We had very little experience in wood production machines, so having that backup was especially important. Biesse was very supportive in terms of onboarding us and training us to use the machines."

Global Doors went from purchasing in all their MFC components, to manufacturing them themselves, which meant they were able to fulfil customers needs much quicker.

The Selco WN2 is a capacious sizing machine. It’s been purpose-designed for smaller businesses and it makes an ideal step up from a conventional saw that will enhance productivity significantly and improve machining quality, even when cutting thin or flexible panels. Reliable and easy to use, it’s a robust saw with a modest price tag.

With the Selco WN2 comes bOpti optimisation software, an easy and intuitive program with clear, real time graphics to aid processing. It can calculate the best solution to minimise material use, cutting times and production costs.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil