At Ligna 2023, the world saw the first public presentation of Biesse’s new Hydrogen Force System.

At Ligna 2023, the world saw the first public presentation of Biesse’s new Hydrogen Force System. Capable of edgebanding 1.5 km of panels with just 1 litre of water.

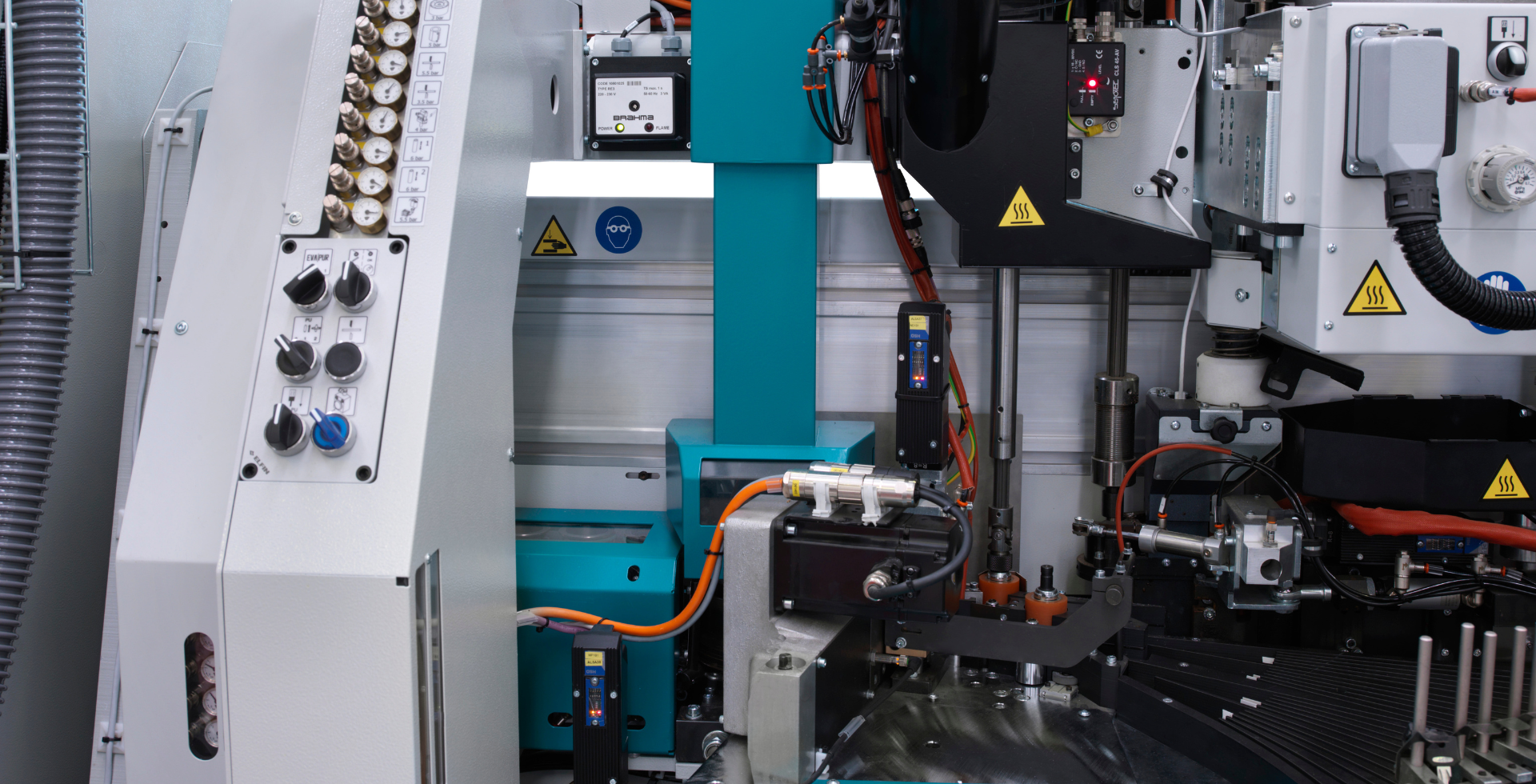

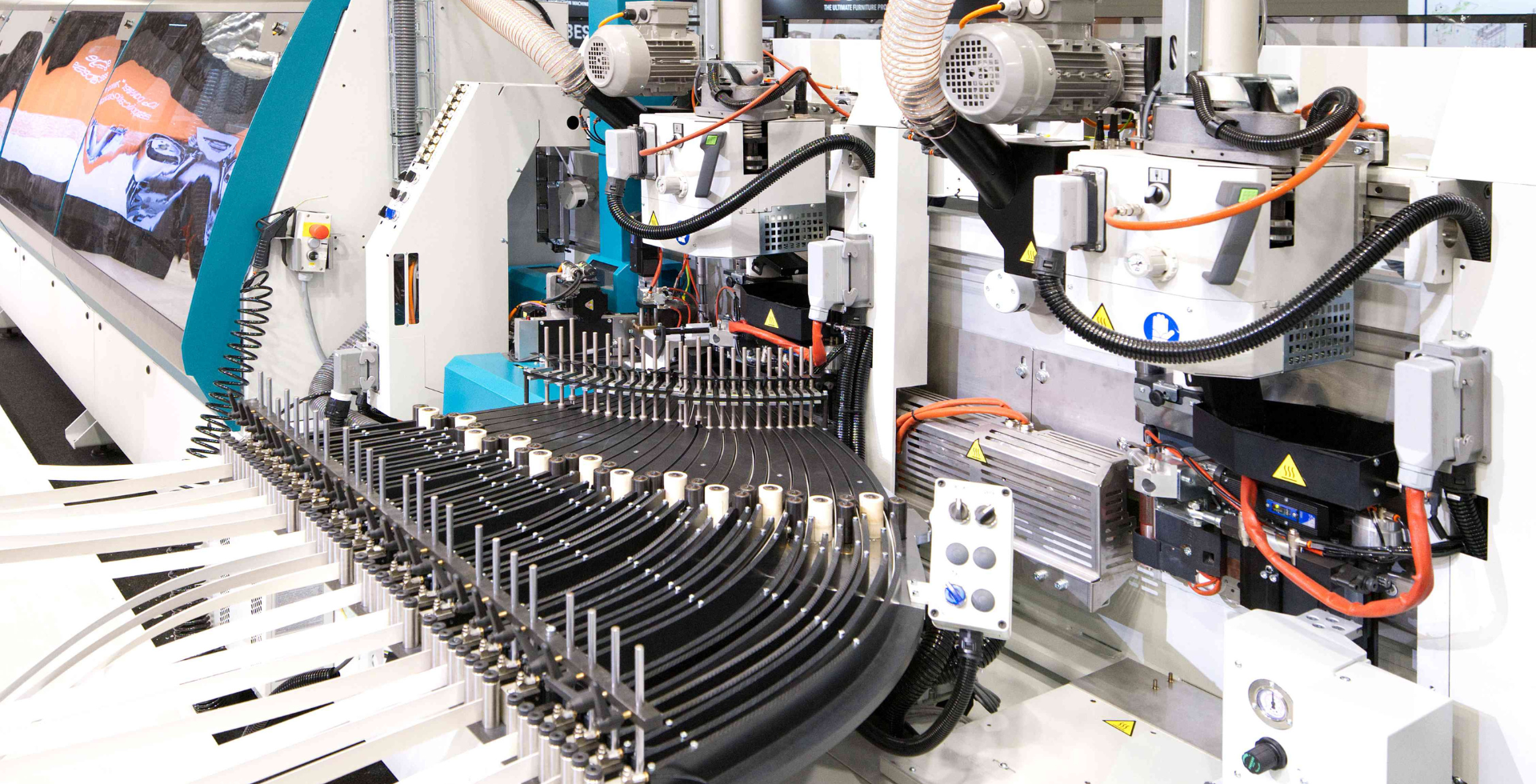

In a blaze of lights, centre stage on a newly liveried stand was a giant Stream MDS edgebander with a dozen-roll tape magazine. To one side, an LED screen flashed messages about an innovative system for perfect bonding.

HFS Hydrogen Force System is a Biesse Technology that begins with H2O and leverages the hydrolysis process to create hydrogen used as a sustainable energy source to power the edge application process, thus reducing energy consumption and related CO2 emissions.

The market is demanding machines with lower running costs so it was always in the back of the mind that we should have a look at a technology that could replace the currently available solutions in the market and provide similar, or better performance. The solution we found was the Hydrogen Force System.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil