Drilling into knowledge

Biesse has supported Unitech Oxon in this efficiency drive by equipping the Rover B with features including a 32 spindle drill block and showing operators how to use this bigger drill block to increase machine productivity.

“Drilling can account for 60% of overall nesting time,” explains Mark Trapnell, the Biesse area sales manager who led this project. “For a company like Unitech Oxon, who are high speed nesting and turning out a lot of panels that require drilling, having the wrong number of drills in the drill block can slow the process right down.”

This is exactly what was happening at Unitech Oxon with its previous machine.

“With our old machine, although we had a drilling block, we weren’t using it in an efficient way. Mark showed us how to use it properly - multi-drilling rather than pecking - and this changed the way we worked. Now, if we have a line of holes that need drilling, instead of drilling each hole individually, the drill block drops five drills down and drills five holes simultaneously,” says Adam.

He estimates that this shaves approximately one minute of drilling time per panel, which may not seem much, but adds up over the course of a day.

“By the end of the day, this amounts to a time saving of up to an hour,” says Adam.

Cumulative savings

When this is combined with the time saved by the streamlined loading and offloading operation, up to two hours a day are accrued - and that doesn’t even take into account the faster processing time of the Rover B.

“The time it takes to load a panel, to machine that panel, and to offload that panel is significantly faster than with our old machine,” says Kevin. “Previously, if we had screwed an operator’s feet to the floor and made him stand there all day long, he would have got 40 sheets of board across it. If we did the same thing with our new machine, we would get in excess of 60 sheets through the machine.”

Whilst Unitech Oxon doesn’t expect to be running at reduced capacity for much longer, when it does revert to a five day operation, it will stick with these production principles to ensure the efficiency is maintained.

“Essentially, the Rover B has forced us to work smarter, which has given us the flexibility to accommodate ebbs and flows in the business,” says Adam.

Dealing with dust

At the same time as its investment in the Rover B, Unitech Oxon installed a new extraction system in the factory to improve the working environment.

The machining of MFC and MDF panels generates large amounts of dust, which has historically been an issue for the company.

When Unitech Oxon heard about the award-winning T-JET feature that is available as an add-on to the Rover B, it was excited about the prospect of seeing whether this dust mitigation solution could work alongside its new extraction system to contain dust.

“With the old CNC there was an awful lot of dust left on the workpiece because as the router cut through the panel, dust fell into the channel,” explains Kevin.

T-JET: cleaning while machining

By cleaning the cut line as the dust is produced, Biesse’s T-JET offers a simple yet unique solution to this problem. A set of high pressured nozzles are mounted to the rotating c-axis and follows the cut line, dislodging any dust that has settled in the cutting channel. As soon as it becomes airborne, the dust is removed by the extraction system so that channels are clean and free from dust.

Cleaning whilst machining is a simple enough concept but designing a rotating air jet system that can keep up with the tool as it changes direction and turns corners is no mean engineering feat. In this respect, T-JET represents a breakthrough solution - an achievement that was recognised when Biesse received the IWF 2022 Challengers Award for T-JET.

With targeted dust collection at the point of production, no further cleaning of the flat bed is required. This supports Unitech Oxon’s efficiency gains as the operator can simply offload the panels and start the next programme straight away, rather than having to clean the bed between programmes using a vacuum cleaner or sweeping arm. From an operator perspective, T-JET mitigates the amount of residual dust that remains in the working environment.

Unitech Oxon says the combination of the T-JET and the new extraction system has created a vastly improved working environment.

“It is a different workplace,” notes Kevin. “Previously there was dust everywhere - in the offices, on the computer screens. Assisted by the T-JET, the new extraction system has eliminated the issue of dust in the workplace.”

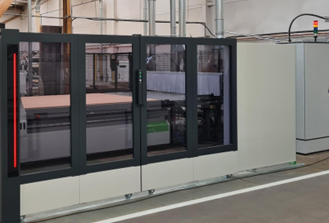

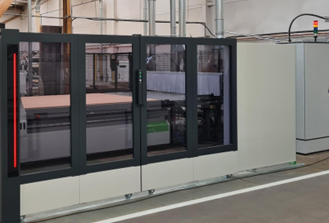

Stream A Smart: gaining an edge

On the back of its positive experience with the Rover B, Unitech Oxon has placed an order for a Stream A Smart edgebander equipped with Biesse’s innovative AR70 corner rounding unit.

Its aim is to enhance the finish on the doors it produces for the contract market whilst improving efficiency. Historically, edging was applied using coloured glues, which meant different colours for different boards. The new edgebander will facilitate the switch to a transparent PUR glue that can be used across all doors, resulting in a thinner, more moisture resistant glue line and a faster process.

The decision to change its approach to gluing came from attending a Biesse Edgebanding Masterclass. “Although I have been in the industry a long time, I am essentially self-taught - there is no ‘university of edgebanding’ - so it has been great to learn from Biesse. The team there has been generous in sharing its knowledge and has supported us in the implementation of its technology every step of the way,” says Kevin.

He adds: “The Rover B and the Stream A Smart are part of an investment strategy that will streamline the business and get us in the best shape to grow and move forward.”

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil