Products

Filter by technology

Wide Belt Sanders

S211

The most compact, high-performance wide belt sanding machine for woodwork in its category

Wide Belt Sanders

S1

The wide belt sanding machine for wood that combines high performance standards with reduced working dimensions.

Wide Belt Sanders

S2

This wide belt sanding machine for wood offers superior levels of performance for a modest investment

Wide Belt Sanders

OPERA 5

Opera 5 is the modular finishing centre that can be used in any type of application; it represents the ultimate expression of configurability

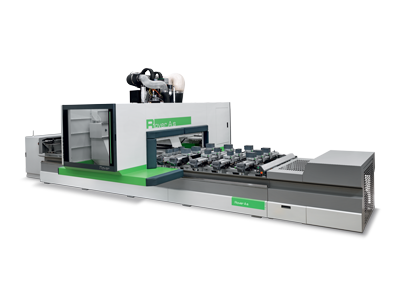

Wide Belt Sanders

OPERA 7

A finishing center designed for large enterprises that enables processing operations to be performed using high-productivity automatic production systems, ensuring consistent performance quality.

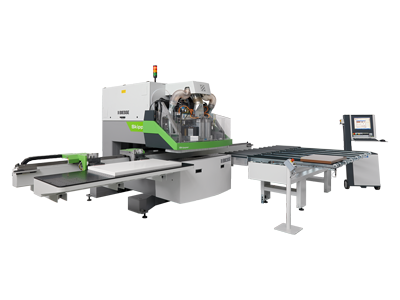

Wide Belt Sanders

OPERA R

This woodworking wide belt sanding machine is unique, offering levels of machinability, precision and quality never before obtained with the technology of this sector.

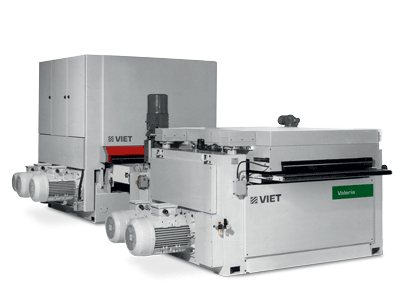

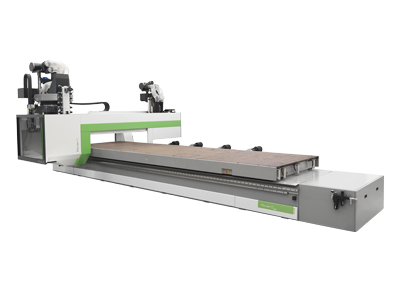

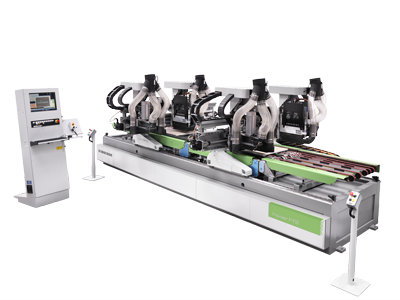

Wide Belt Sanders

VALERIA

Valeria is the calibration-sanding center designed for large-scale industry applications. It is ideal for heavy-duty processing, allowing precision machining on high-speed production lines.

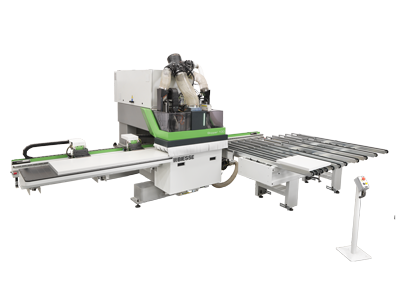

Wide Belt Sanders

NARROW

The finishing center designed for big industry, that allows for the machining and sanding of long, narrow pieces of wood (skirting, wood flooring, strips, frames, building beams, windows).

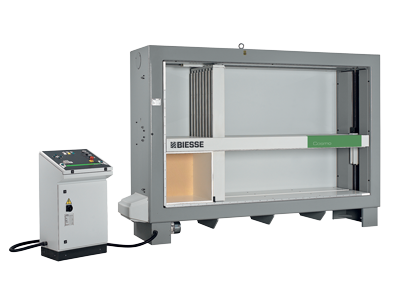

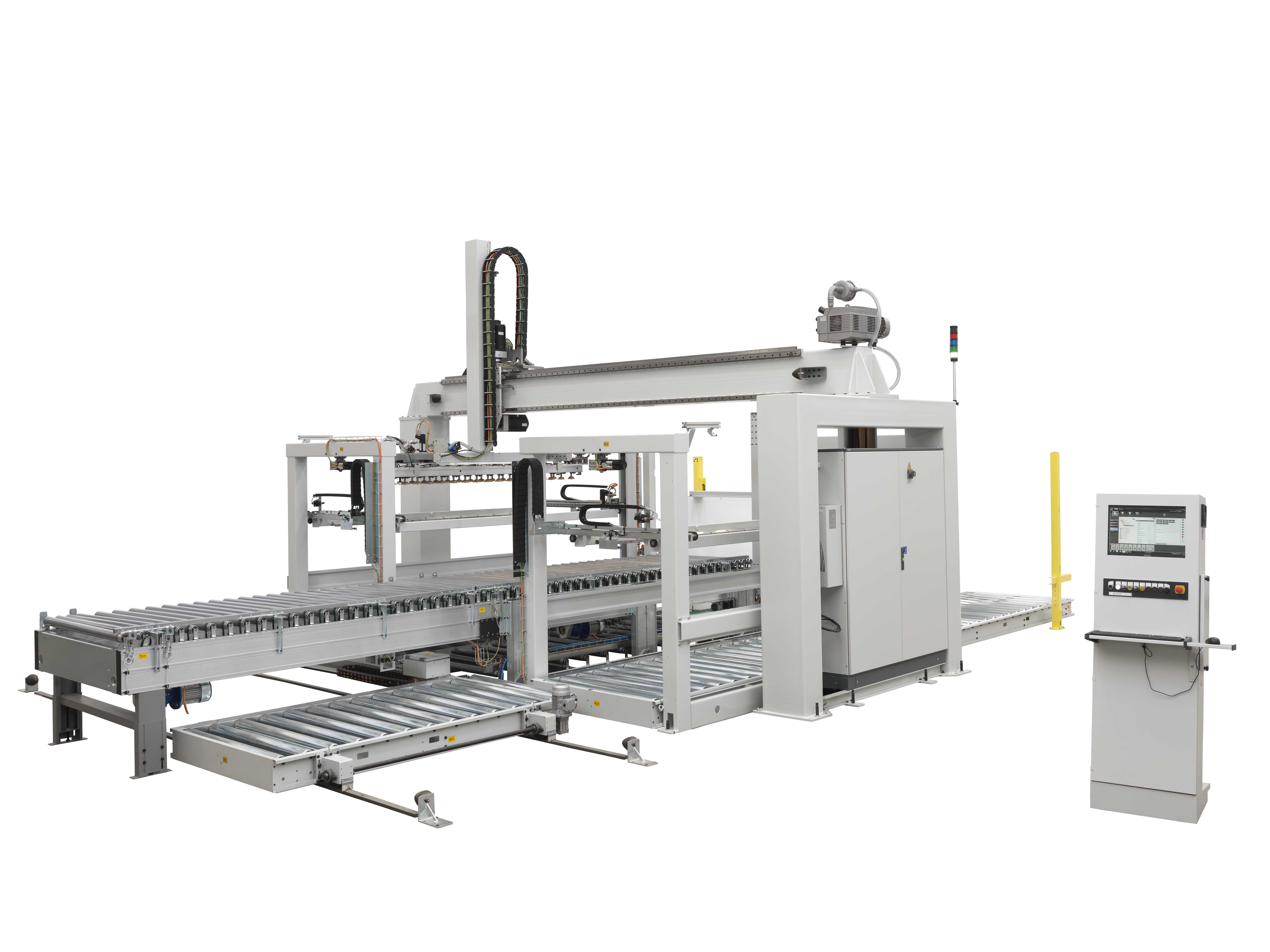

Case Clamps machine

COSMO

The ideal solution for meeting all assembly needs for furniture both for the artisan and in the made-to-measure production departments of the industry.

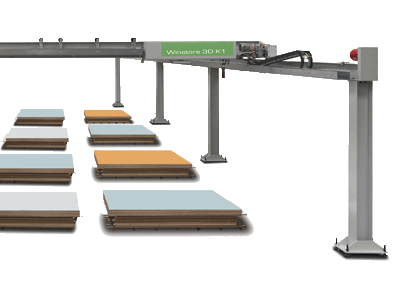

Material Handling Systems

WINSTORE

The automated material handling magazine for the optimized management of panels for large contract manufacturers, which guarantees production with reduced times and costs.

Material Handling Systems

WINNER W4

The material handling loading system that's fully integrated with single-sided edgebanding machines for the automatic management of panels waiting to be edgebanded.

Material Handling Systems

WINNER W1

Winner W1 is the range of panel loading and unloading systems for high-performance, automated lines that are particularly suited to square-edgebanding and boring lines. Flexible confiurations that can be customised depending on the customer logistic setup.

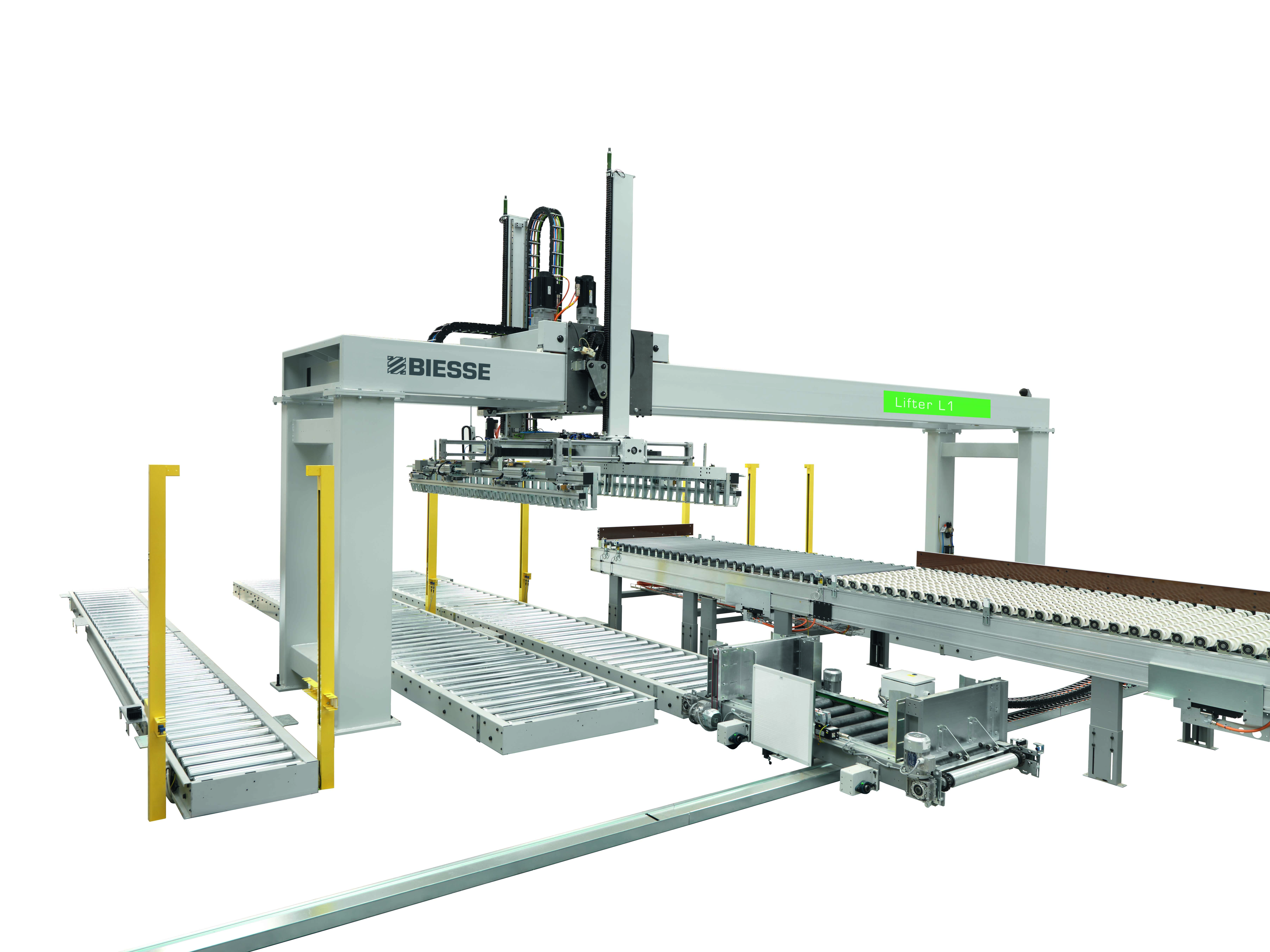

Material Handling Systems

LIFTER

Lifter, gripper unloading system for high-productivity angular cutting systems. Integrated software management for the perfect synchronization between cutting scheme and unloading configuration.

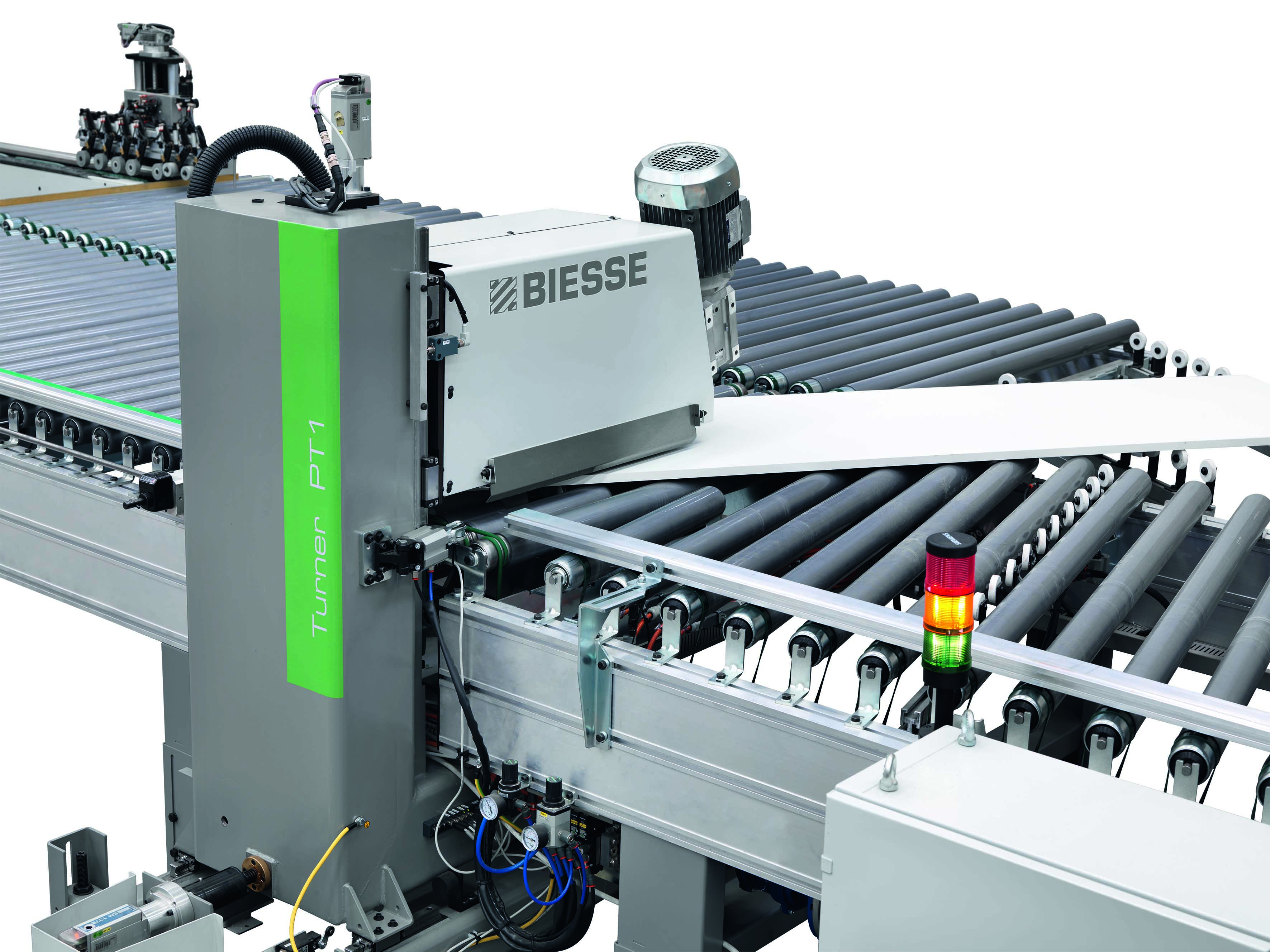

Material Handling Systems

Turner PT

Turner PT panel turners are ideal for high-productivity square-edging lines. 90° rotation achieved using two padded, motorized inverter-controlled cones.

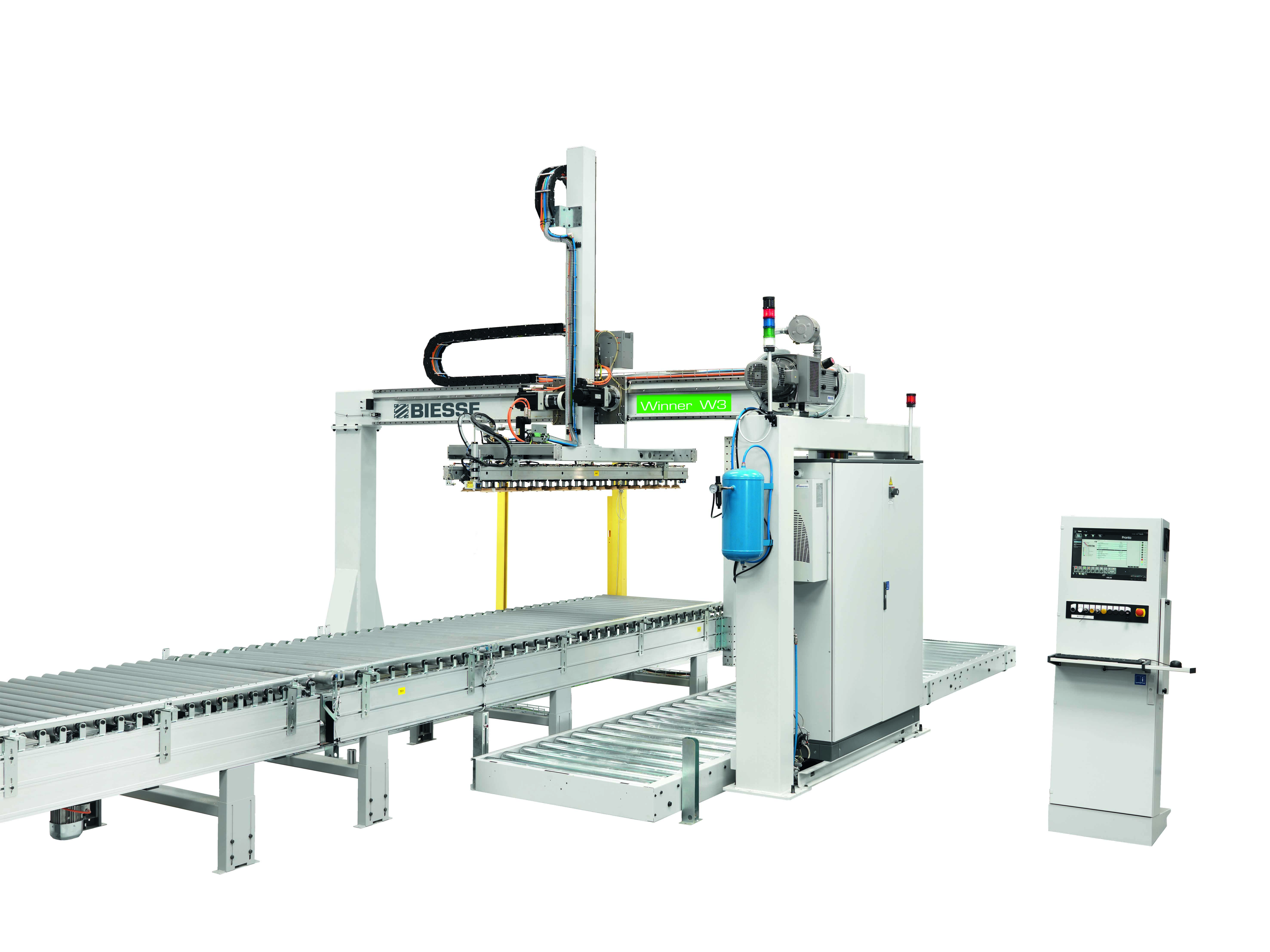

Material Handling Systems

Winner W3

This material handling system allows for the loading and uploading panels in lines with high machining flexibility to manage project stacks.

Material Handling Systems

WINNER W2

Winner W2 is the material handling solution for medium-high performance loading and unloading lines, where high handling speed and security of panel detachment are the pre-requisites for loading continuity. Ideal for flexible boring processes, where required productivity is of 22-26 panels per minute.

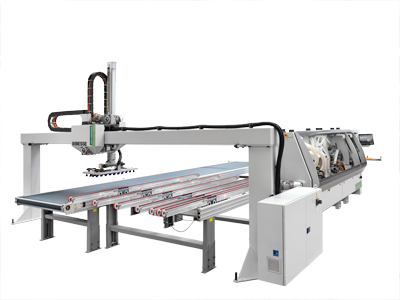

CNC Machines for Windows and Doors

ROVER A 16

The CNC machining center for the manufacturing of furniture, window frames, and door frames

CNC Machines for Windows and Doors

ROVER B

The CNC machining center designed for both skilled craftsmen and largescale industry

CNC Machines for Windows and Doors

ROVER C

The new CNC machine for manufacturing furniture, staircases, and door and window components of any shape, size, and thickness with ease

CNC Edge banders

ROVER A EDGE 15/18

The new CNC edgebanding center with a gantry structure, designed to produce shaped, edgebanded panels on a single machine

CNC Machines for Windows and Doors

ROVER A

Rover A is the new CNC machine offering top performance and flexibility. It’s designed for the customer who wants to invest in a product that can process any type of element quickly and economically

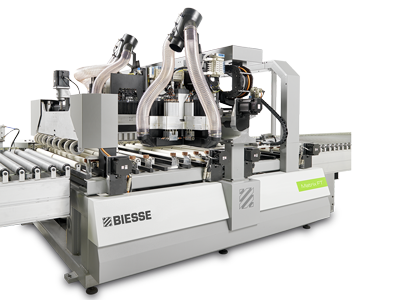

Cnc drilling and milling machine

ELIX

Elix is the hole boring machine for point-point dowels that is perfect for flexibly carrying out boring operations or boring and insertion operations for the manufacturing of kitchens, furniture, drawers, and small pieces.

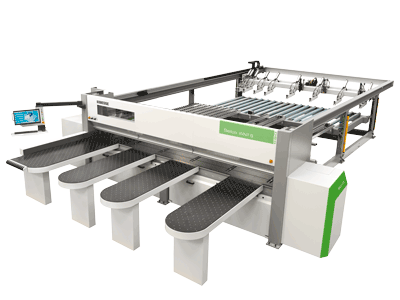

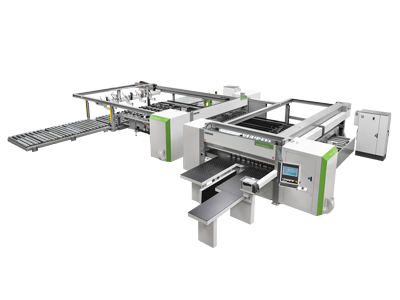

Panel Saws

SELCO SK 3

The range of horizontal panel and beam saws for panel sizing, able to satisfy the needs of small and medium companies, specifically designed for single parts production or small series.

Panel Saws

SELCO WN 2

The range of horizontal beam and panel saws for businesses making their first investment to improve production and machining quality by moving from conventional manual machinery to numerically controlled technology with high precision machining and reliability.

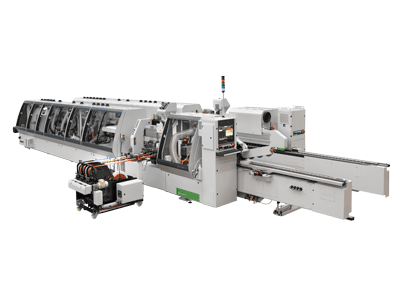

Edgebanding Machines

AKRON 1100

The smallest automatic single-sided edgebanding machine of the range and the only one of its kind on the market. This edgebanding machine is designed for small-scale artisans and companies looking for user-friendliness and optimum quality - common features of all Biesse machines

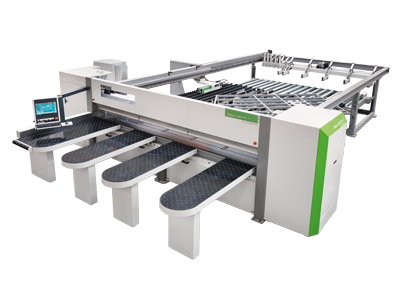

Panel Saws

SELCO SK 4

SELCO SK 4 is the range of horizontal beam and panel saws designed to satisfy the needs of small to medium production. It is easy to use with advanced technical solutions making it the reference point in its sector.

Edgebanding Machines

JADE 200

A range of automatic single-sided edgebanding machines purposely created for craftsmen and companies looking for user-friendly, customized production and flexible solutions in a limited space

Edgebanding Machines

JADE 300

The range of automatic single-sided edgebanding machines designed for artisan craftsmen who want to improve and automate production, or for industry sectors manufacturing made-to-measure products

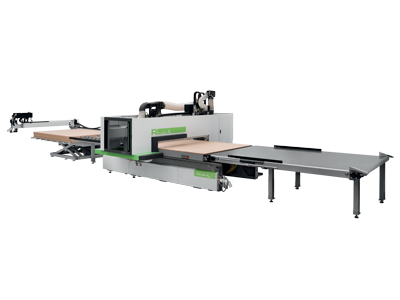

Panel Saws

SELCO WN 6

The result of a project developed with the latest technologies. This beam saw adopted revolutionary technical solutions that increase yield and overall machining quality.

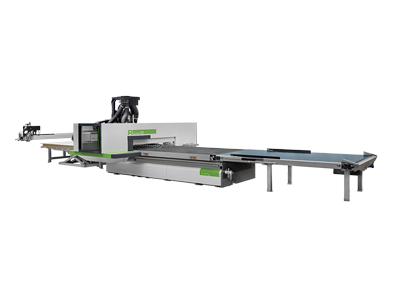

Panel Saws

SELCO WN 7

The top of the range of horizontal beam saws with one cutting line: high performance in reduced times to meet the needs of medium and large production requirements.

Edgebanding Machines

AKRON 1300

A range of automatic single-sided edgebanding machines purposely created for craftsmen and companies looking for a flexible solution that is user-friendly, and has the ability for customized production in a limited space

Edgebanding Machines

AKRON 1400

A range of single-sided edgebanding machines for the application of edging in either rolls or strips

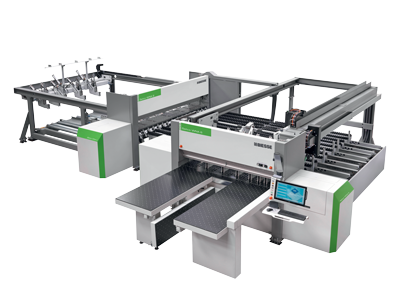

Panel Saws

SELCO WNA 6

A range of cutting systems offering two fully independent cutting lines with automated loading that respond to the requirements of the furniture and semi-finished product industries.

Edgebanding Machines

STREAM A SMART

Stream A SMART is the new range of automatic single-sided edgebanding machines, designed for artisan producers and small companies looking for ease of use and customized production.

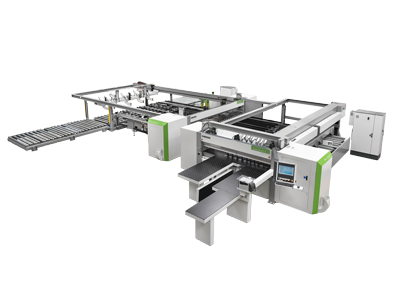

Panel Saws

SELCO WNA 7

A range of cutting systems offering two fully independent cutting lines with automated loading that respond to the requirements of the furniture industry.

Edgebanding Machines

STREAM A

The new range of automated single-sided edgebanding machines aimed at medium size companies who wish to increase their production capacity

Edgebanding Machines

STREAM B

A single sided edgebander that meets the needs of large companies for high productivity

Panel Saws

SELCO WNA 8

A range of sizing systems with two fully independent cutting lines and automatic loading. Ideal for the needs of major businesses that not only produce large batches but also focus on the dynamic, personalized production of small batches.

Edgebanding Machines

STREAM C

The range of square and edgebanding machines which enables both squaring and edgebanding operations to be carried out using a single system, on both the transverse and longitudinal sides of a panel

Panel Saws

NEXTSTEP

The only solution on the market that combines two processes in one: the flexibility of a machine with a router and the precision of a squaring machine.

CNC Edge banders

ROVER A EDGE 16

A CNC edgebanding machining center that supports the machining of shaped panels, which can be edgebanded on a single, compact, high performance machine

Edgebanding Machines

STREAM B MDS

Stream B MDS is the flexible single-sided squaring and edge banding machine ideal for small batches, which responds to the total flexibility needs of medium and large industries, performing squaring and finished measurement of panels of different formats. It allows you to work on batch-1 in a simple and rational way because it is designed to minimize space constraints, costs and impacts on the factory.

CNC Edge banders

ROVER B EDGE

Edgebanding CNC machining centers from the Rover B Edge range allow users to carry out machining operations to shape and edgeband panels on a single machine.

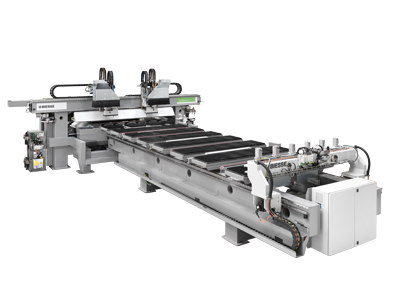

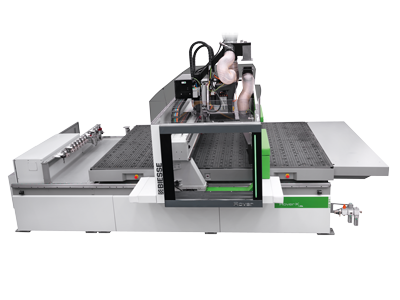

CNC Routers

ROVER K FT

Easy and compact machining center for high quality NC nesting production.

CNC Routers

ROVER A FT

Biesse's new high-performance CNC router table for nesting operations. Created for companies looking for a compact yet efficient router that offers top-of-the-range technology and guarantees optimum precision in every machining operation

CNC Machining Centers

ROVER GOLD

The compact machining centre designed for high performances capable of meeting various levels of production requirements

Cnc drilling and milling machine

BREMA EKO 2.1

The compact and versatile vertical boring machine that supports the machining of different thickness and size formats within a reduced footprint.

CNC Routers

ROVER B FT

The Rover B FT machining center for nesting raises the quality and productivity standards in this sector. Thanks to its structure and the variety of possible configurations, it can keep abreast of the work rhythm of medium and large companies for the production of pieces for every type of application.

Edgebanding Machines

Stream Edge Pro

Stream Edge Pro is the ideal flexible single-sided squaring and edgebanding machine for small batches that can be integrated into automatic production lines. It guarantees increased productivity, squareness and finished panels of different shapes and sizes. Designed to minimize factory floor footprint, costs and impact, it allows users to perform Batch-one operations both simply and effectively.

CNC Routers

ROVER B FT HD

ROVER B FT HD is the new high performance router table dedicated to nesting operations. Designed for high speeds and optimum accelerations, it takes its position as the most productive machine on the market.

CNC Routers

Rover C FT

The new stand alone 5 axis and 4 axis CNC Router has been designed not only for wood nesting, but also for processing thick panels, mixed and complex production runs, as well as machining aluminium and other technological materials.

CNC Machines for Windows and Doors

WINLINE

Flexible and productive solution for windows and doors application.

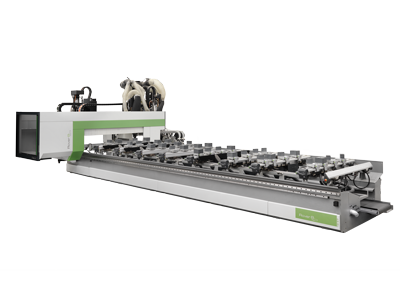

Cnc drilling and milling machine

BREMA EKO 2.2

The new compact and versatile vertical boring machine with a reduced footprint, for machining panels of different thickness and sizes.

Cnc drilling and milling machine

SKIPPER 100

The innovative CNC boring processing center that can process panels of different formats in sequence and in “real time”.

CNC Machining Centers

ROVER K SMART

This CNC machine for wood is suitable for artisan and small to medium sized businesses looking for simple solutions and reliability.

Cnc drilling and milling machine

SKIPPER 130

A CNC processing center that allows the processing of panels of completely different formats in sequence and without interruptions

CNC Machining Centers

ROVER AS 15

Our new CNC wood milling machine offering top performance and flexibility. It's designed for the user who wants to invest in a wood CNC Machine that can process any type of element quickly and economically

Cnc drilling and milling machine

INSIDER FT2

A numerically controlled wood boring and drilling machine for production without set-up times.

Cnc drilling and milling machine

MATRIX

Matrix is the NC drilling and inserting machine for line installation that combines versatility, flexibility and performance to manage "on demand" production in the best possible way.

CNC Machining Centers

ROVER A SMART 16

A simple yet efficient wood milling machine. This 5-axis CNC machine is used for producing any type of furnishing item.

CNC Routers

Rover AS FT

Rover AS FT is the CNC router for nesting operations designed for the customer who wants to invest in the growth of their business and the evolution of the production process, obtaining high performance and productivity.

Cnc drilling and milling machine

INSIDER FTT

This flexible wood boring machinery combines the high productivity to the capacity of processing small batches in sequence.

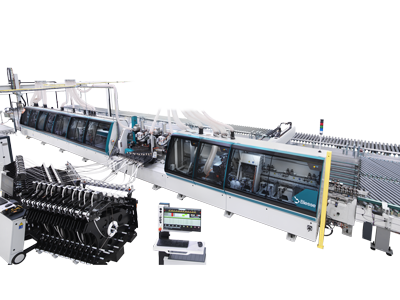

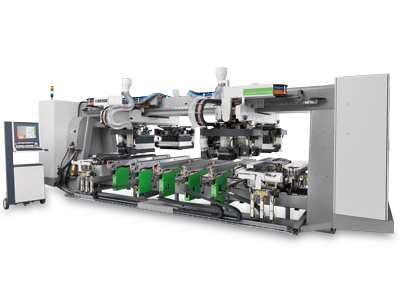

Cnc drilling and milling machine

TECHNO LINE

The Techno series, consisting of Techno FDT, Techno F, Techno S and Techno SDT, is the line of automatic boring and inserting crosswise machines for the processing of top and bottom panel surfaces and its four sides.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

.png)

_400x300.png)

.png)