Technologies

Filter by technology

Reset filter

Material Handling Systems

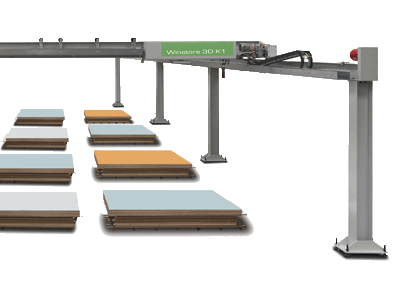

WINSTORE

The automated material handling magazine for the optimized management of panels for large contract manufacturers, which guarantees production with reduced times and costs.

Material Handling Systems

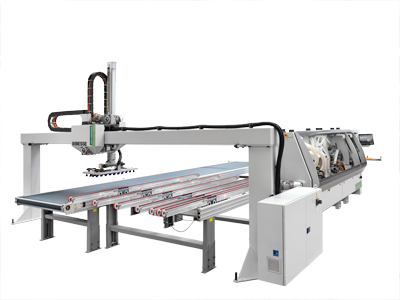

WINNER W4

The material handling loading system that's fully integrated with single-sided edgebanding machines for the automatic management of panels waiting to be edgebanded.

Material Handling Systems

WINNER W1

Winner W1 is the range of panel loading and unloading systems for high-performance, automated lines that are particularly suited to square-edgebanding and boring lines. Flexible confiurations that can be customised depending on the customer logistic setup.

Material Handling Systems

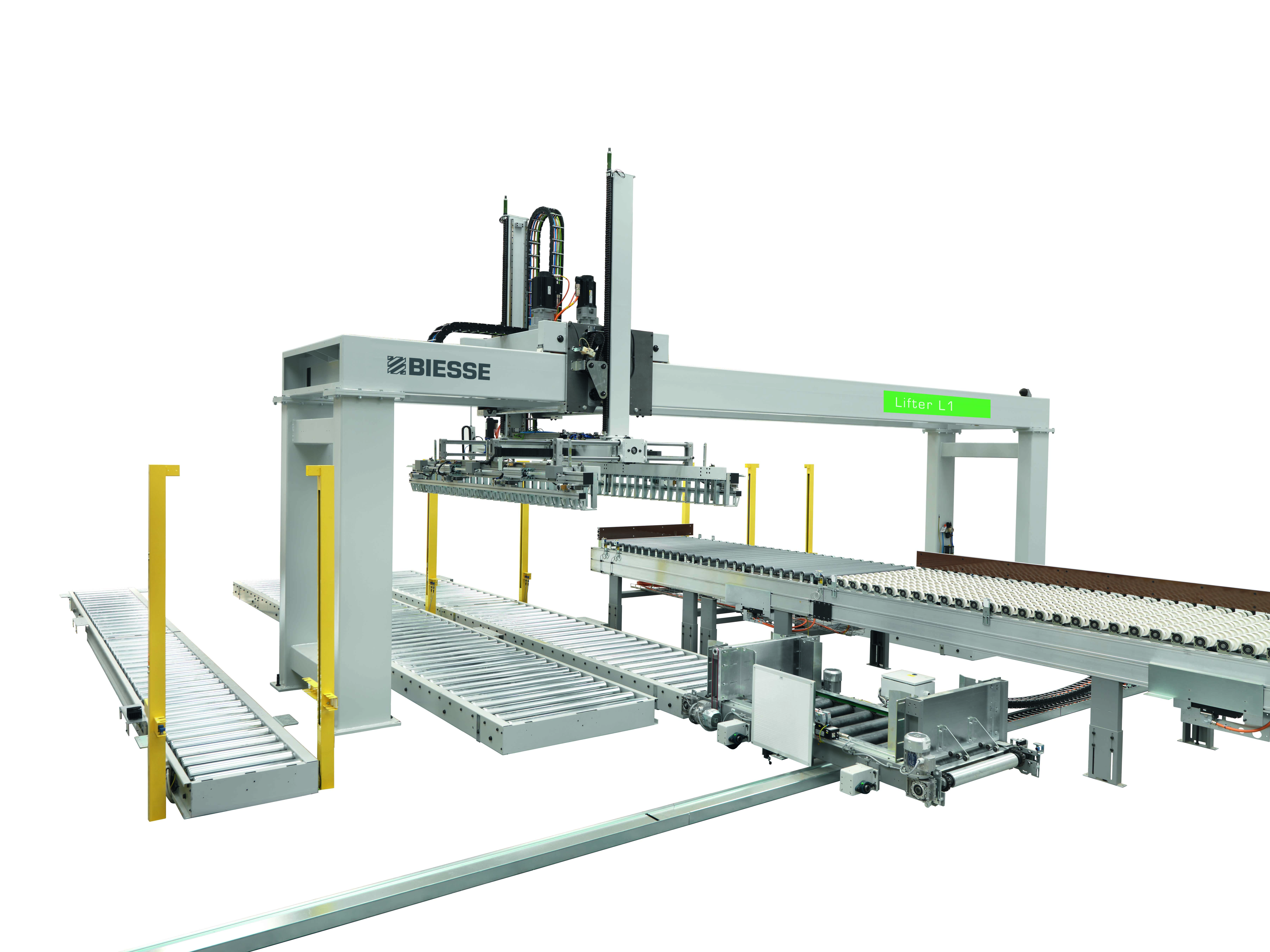

LIFTER

Lifter, gripper unloading system for high-productivity angular cutting systems. Integrated software management for the perfect synchronization between cutting scheme and unloading configuration.

Material Handling Systems

Turner PT

Turner PT panel turners are ideal for high-productivity square-edging lines. 90° rotation achieved using two padded, motorized inverter-controlled cones.

Material Handling Systems

Winner W3

This material handling system allows for the loading and uploading panels in lines with high machining flexibility to manage project stacks.

Material Handling Systems

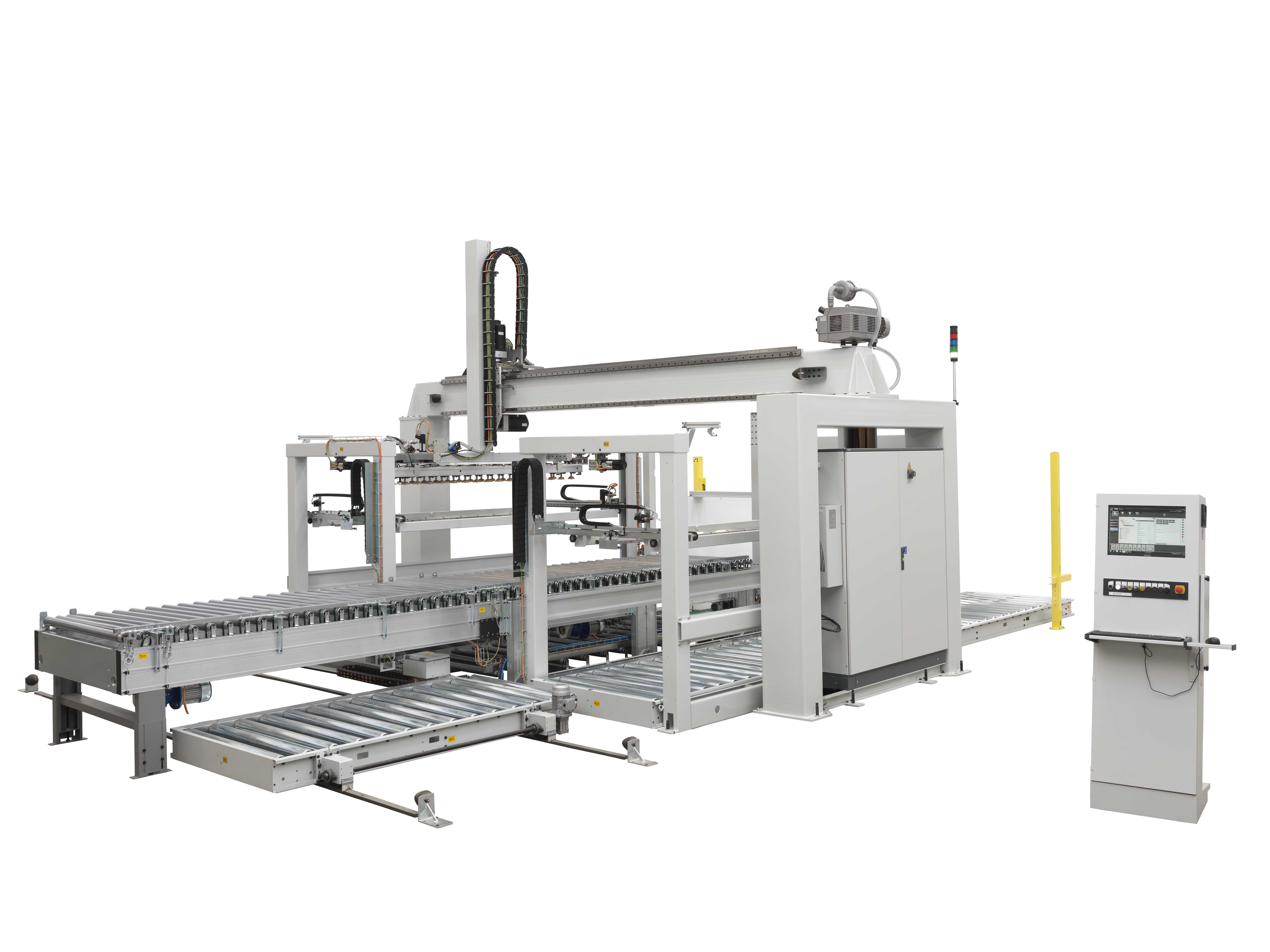

WINNER W2

Winner W2 is the material handling solution for medium-high performance loading and unloading lines, where high handling speed and security of panel detachment are the pre-requisites for loading continuity. Ideal for flexible boring processes, where required productivity is of 22-26 panels per minute.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil