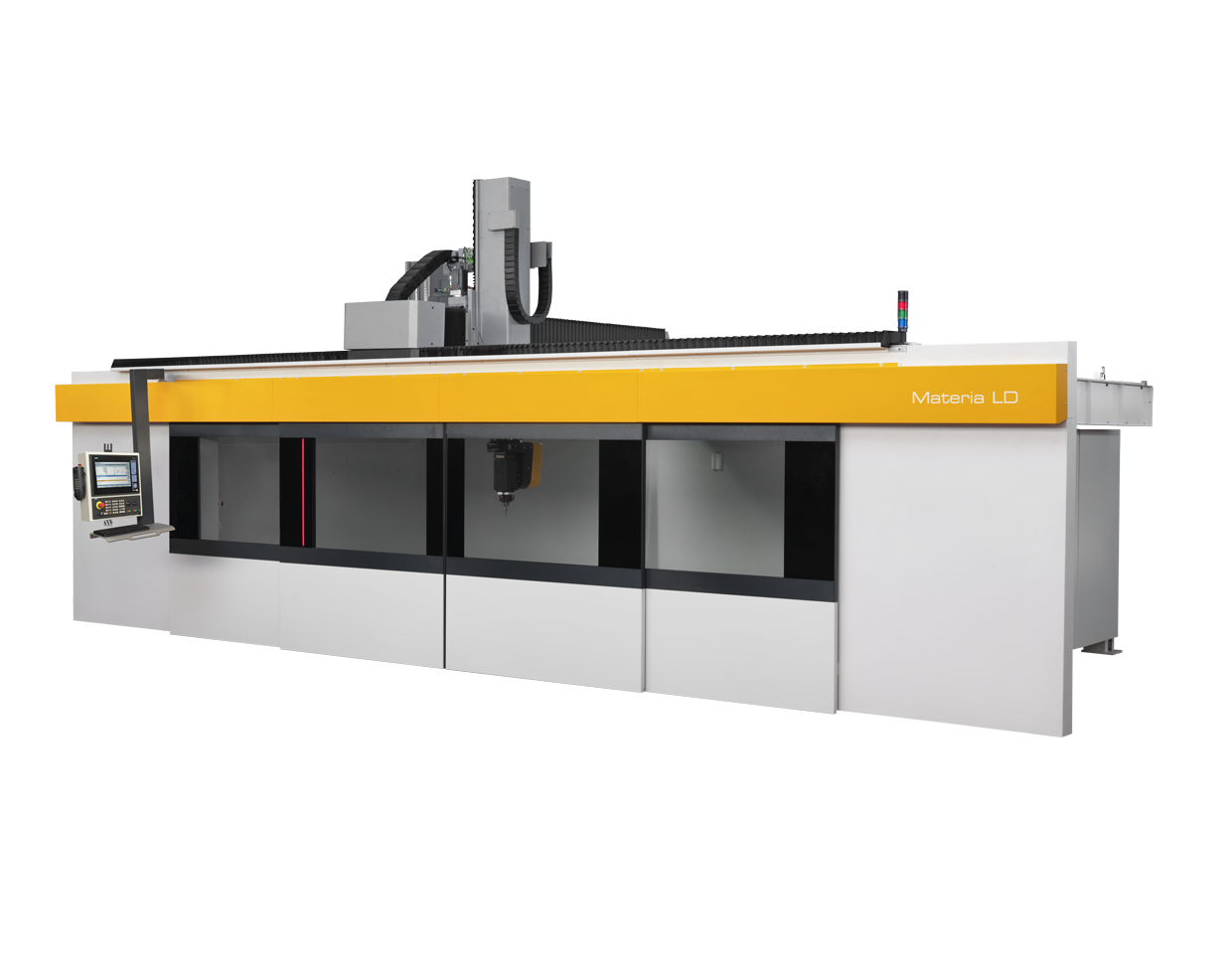

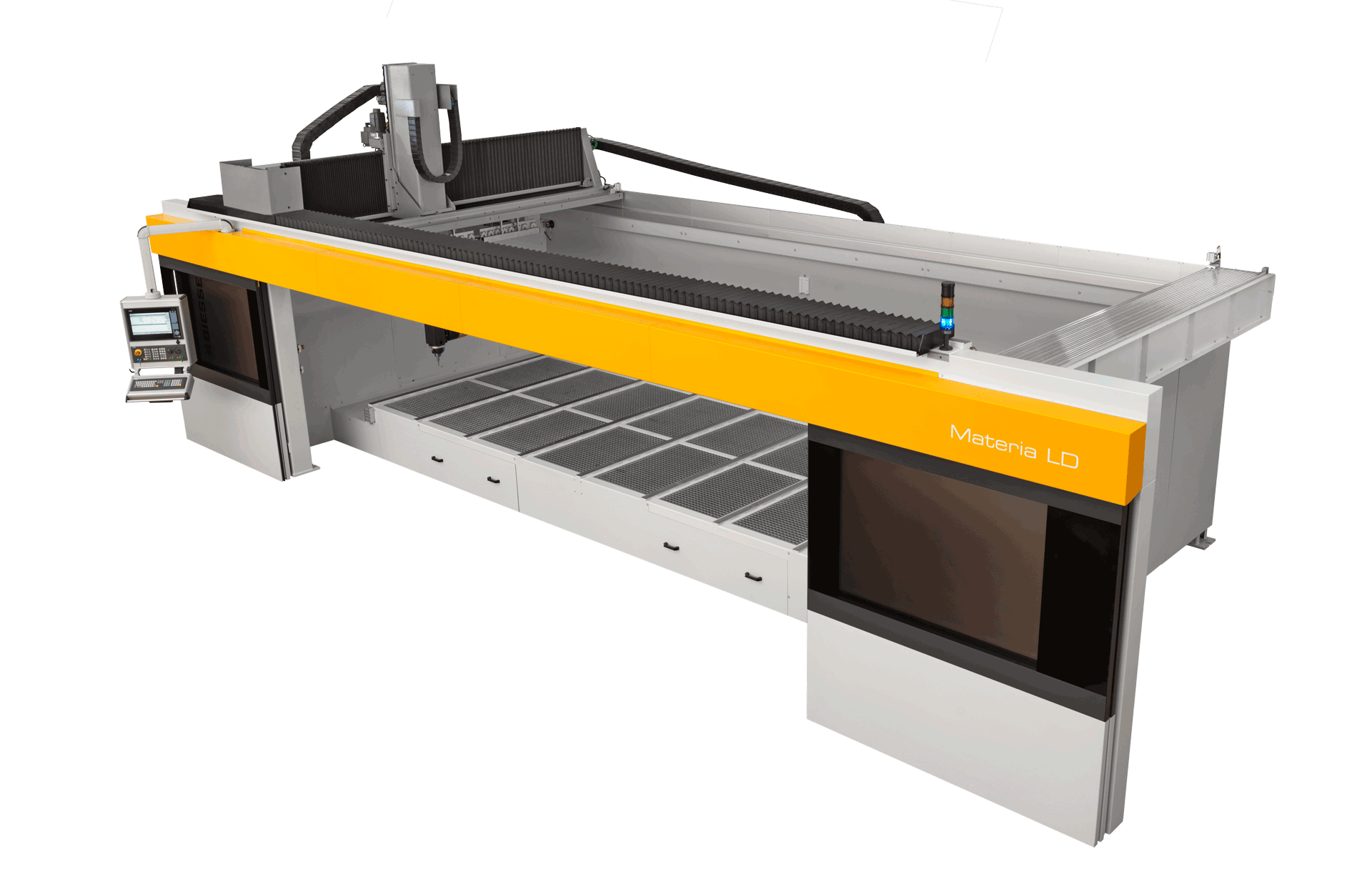

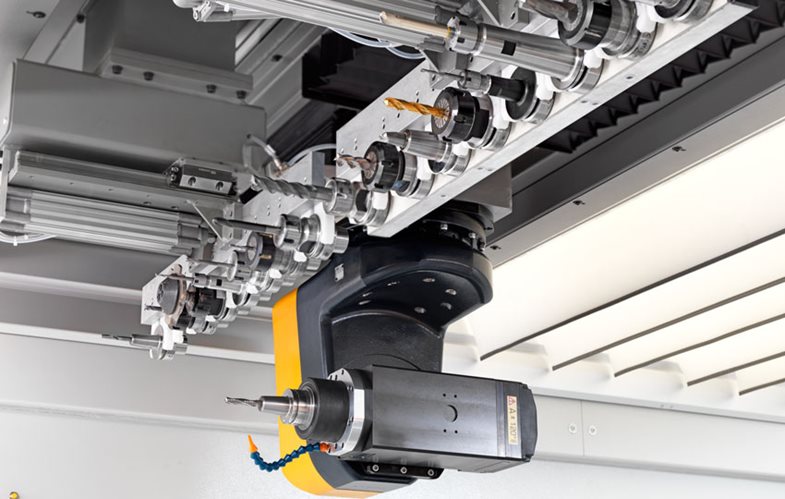

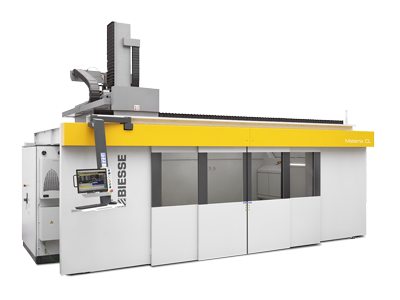

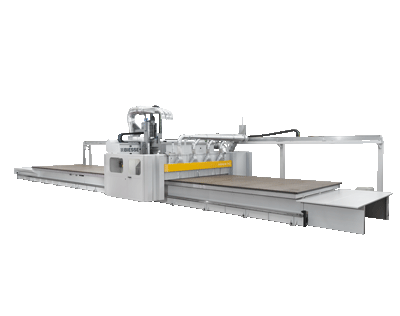

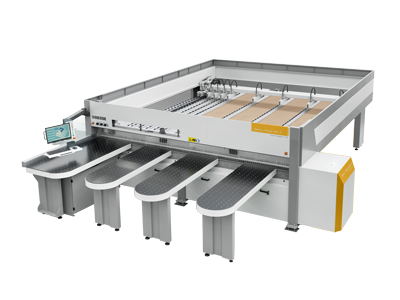

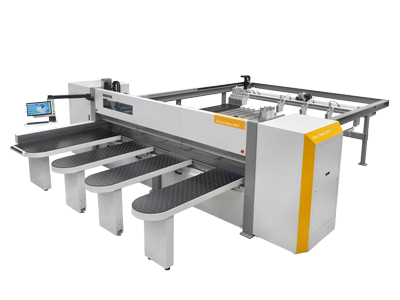

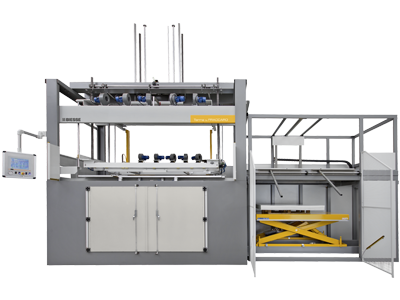

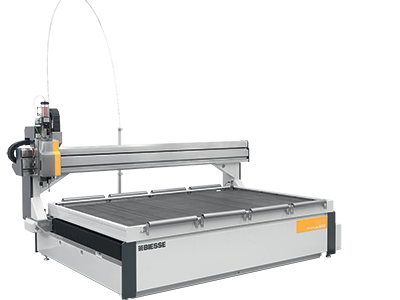

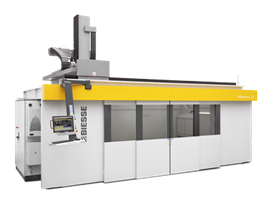

Materia LD, an extremely versatile and multifaceted 5-axis machining centre and gantry processing centre is equipped with a mobile crossbar, designed to meet dynamic and speedy machine requirements in the field of plastic and composite double edge trimming, high-speed milling of resin or aluminium models, and the prototyping of moulds. Catering industries like automobile, aerospace, nautical, motor-sport and moulding sectors, the centre strives to work towards delivering with quality. Ensuring automated processing, Materia LD is better when compared to 3-axis machine processing as it assists a lot more operations than usual. It is growing rapidly in the dynamic industry environment where machining requirements are complex. It is currently in demand for its facility to access up to five sides of a prismatic part in a single setup. Started in the 1950s, the 5-axis machining centre and the technology behind it is no new innovation. It was initially started to accurately process countered air foils for military aircraft wings and helicopter blades. As it has evolved in its technology, it has been able perform high-quality tasks and has replaced traditional cutting tools and milling machines. These help you increase productivity as they can be efficiently scheduled, which is why they’re growing immensely in the industry. 5 axis cnc milling machining have also contributed to fulfilling general and complex machining requirements and has benefited as an economical measure for organizations, as it saves time and labour. Its ability to access a maximum of five sides and effortlessly intricate work pieces helps optimize production and operations.

We simplify your manufacturing process to make the potential of any material shine.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil