Bolstering performance

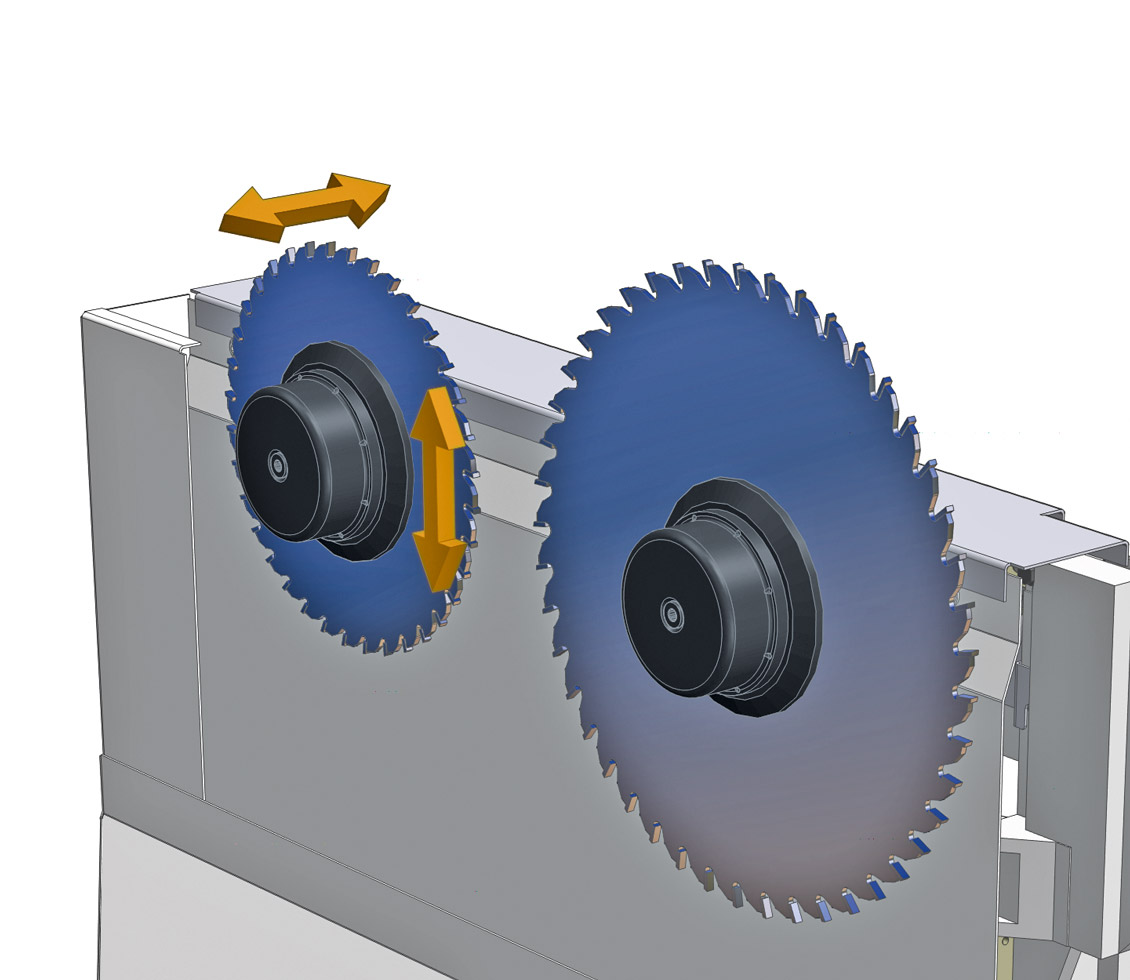

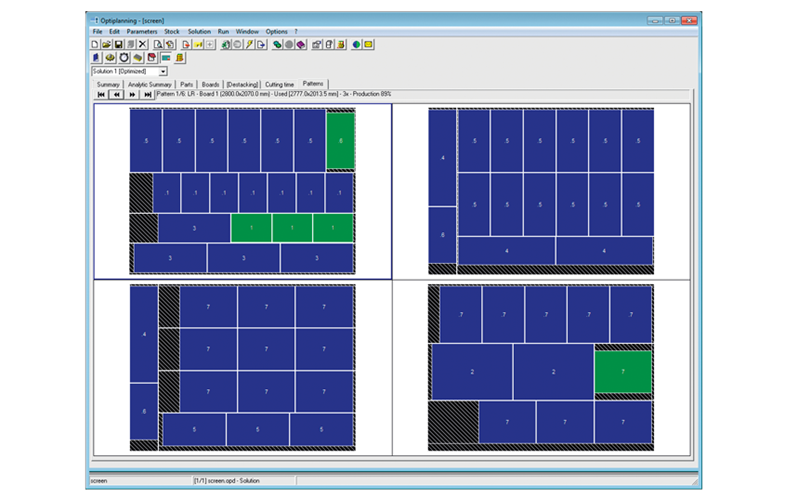

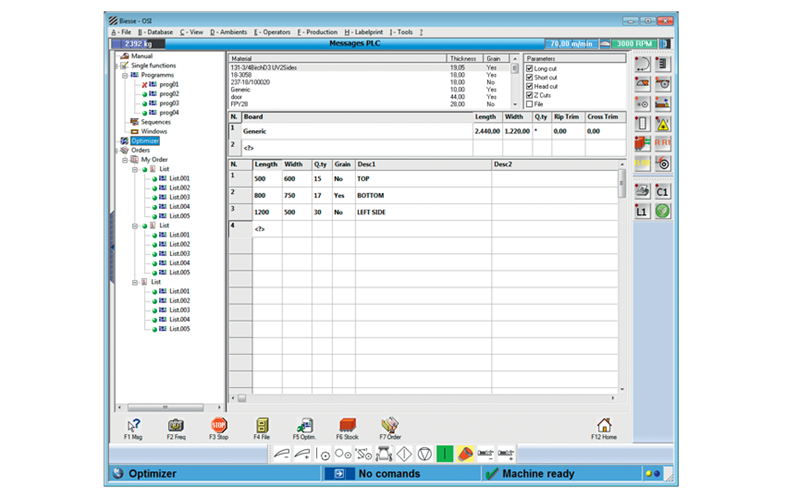

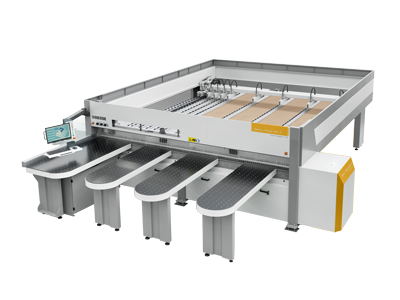

SELCO PLAST WN 7 is positioned at the top of the range of beam saws with one cutting line: high performance in reduced times, to meet the needs of medium and large companies.

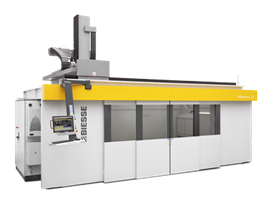

We simplify your manufacturing process to make the potential of any material shine.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil