We simplify your manufacturing process to make the potential of any material shine.

Honing a keen eye for quality and sensitivity to the customer's needs.

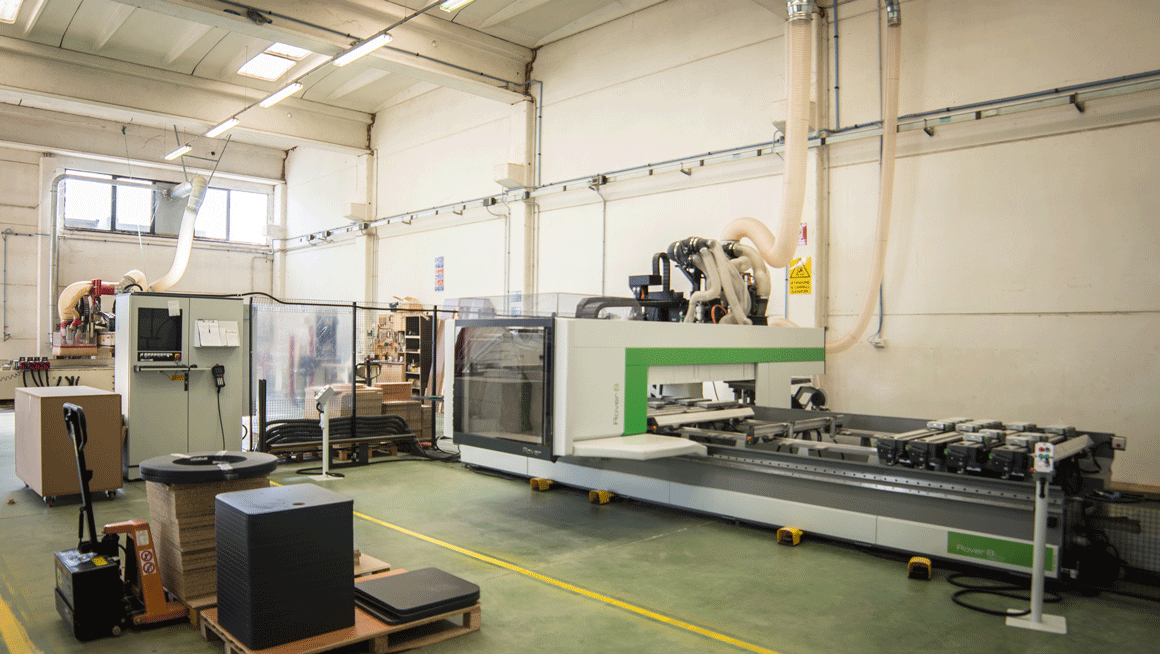

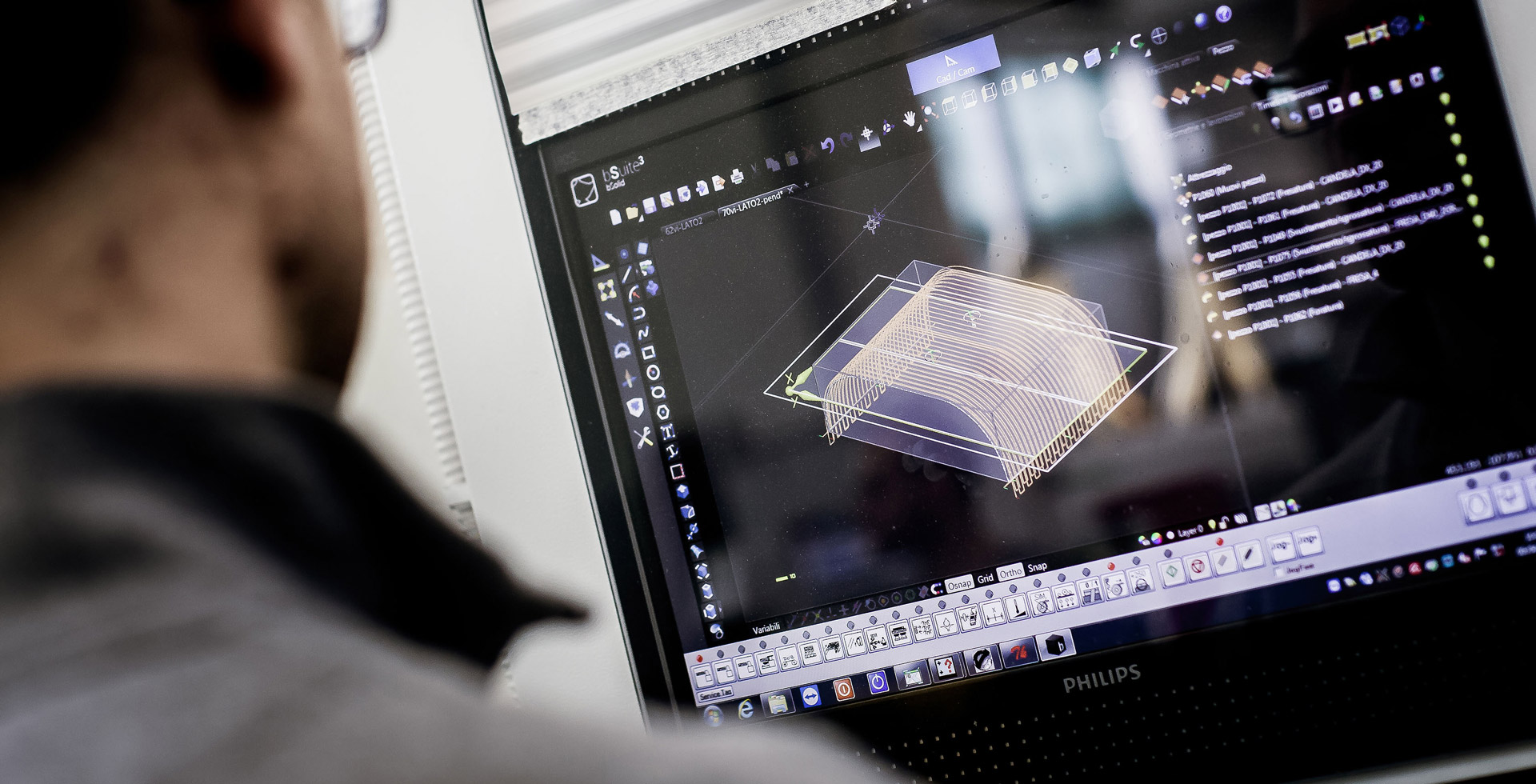

Originally an artisan carpentry business, over time Grottaroli found that the introduction of cutting-edge machinery made special project's possible and helped the company meet customers' needs. ‘Our workshop evolved as it addressed the specific needs of the wood furniture industry and executed machining operations for third parties. We are now equipped to handle the production of small to medium batches of furniture items that are often unique, complex and subject to repeat orders over time. Our company offers a complete service: from the prototype to the assembled finished product’, says Andrea Zenobi, the Head of Production and a partner in the company. Every step and every product is handled with great precision and care, the marks of distinction of an artisan carpentry, and the company offers customers high quality products, ‘We handle all phases of production for our customers. We select the suppliers and the components, industrialise the process, plan and manage production, assemble, package and ultimately deliver the finished product to the contractor or the end customer’, Andrea Zenobi continues.

The flexibility and ease-of-use, offered by the Rover B machining centre, helped us achieve faster delivery and maintain constant quality standards over time

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil