Leading technology for quality products

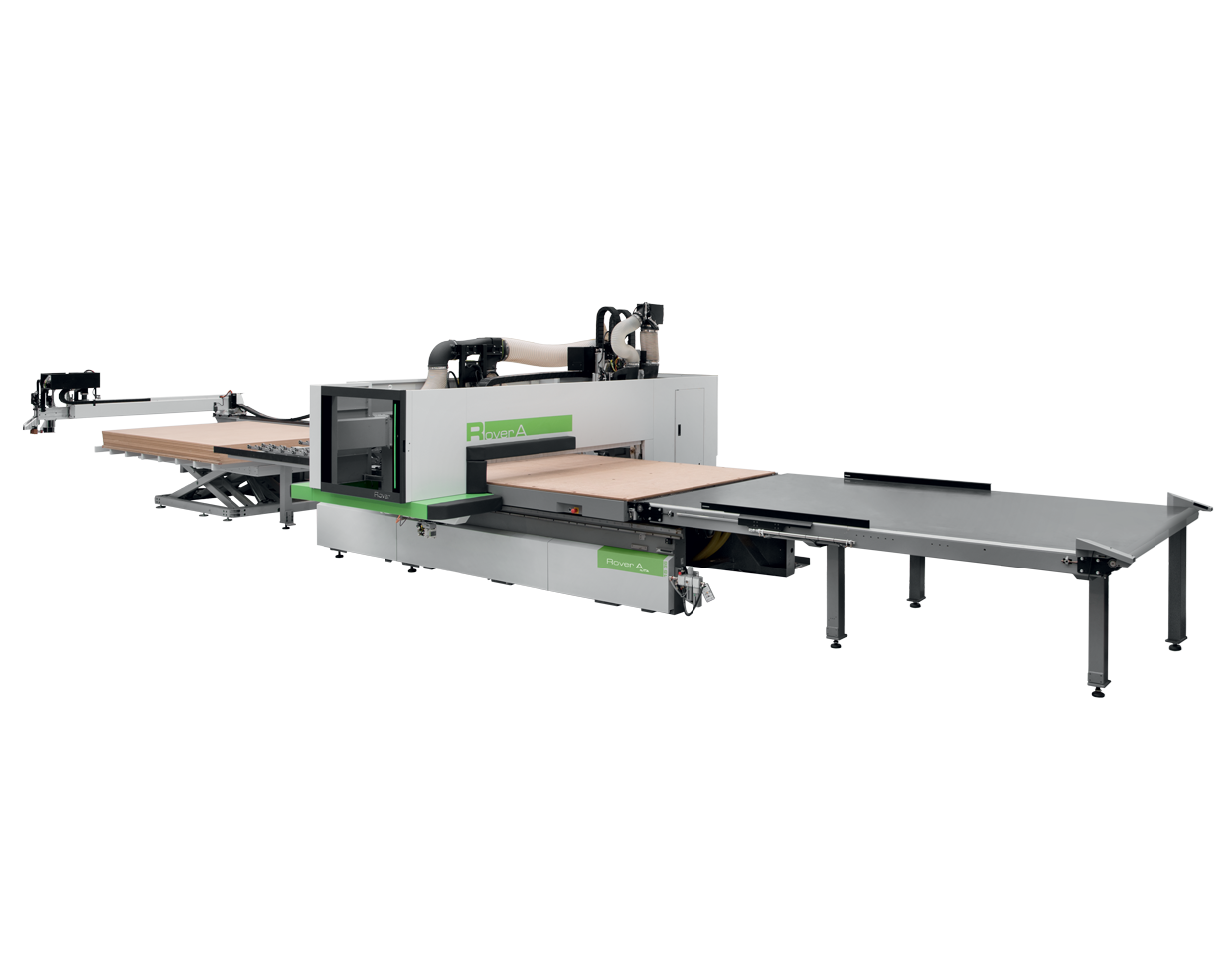

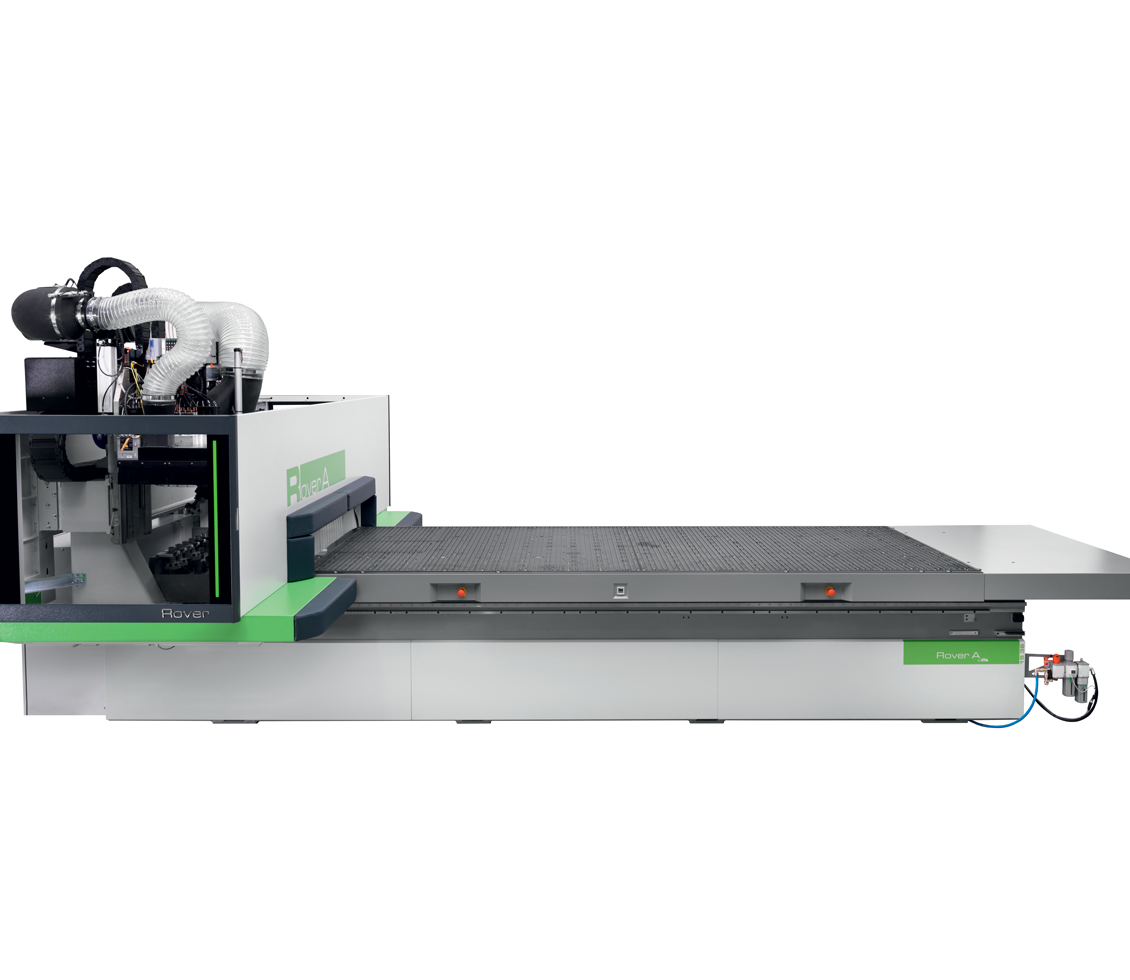

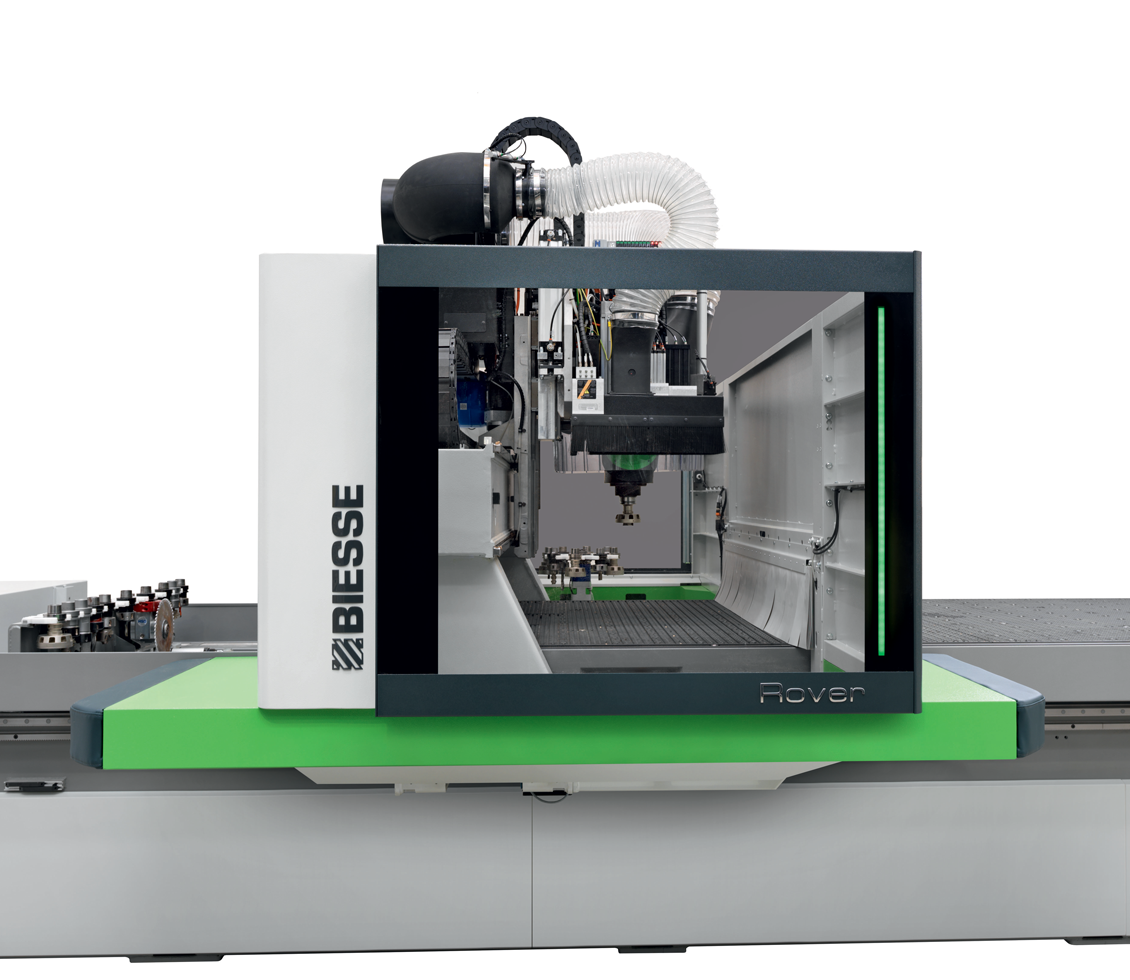

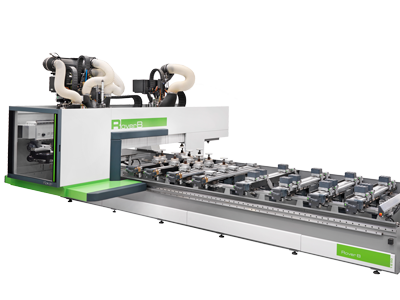

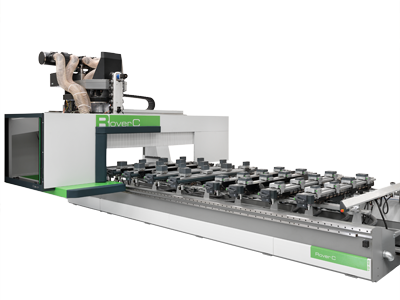

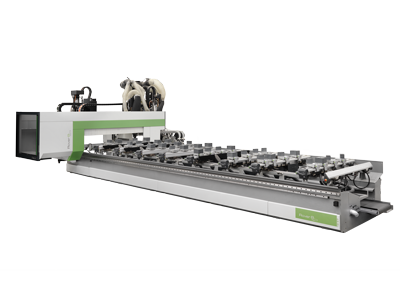

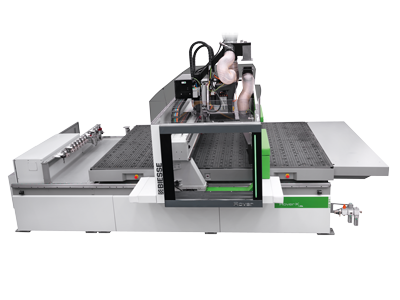

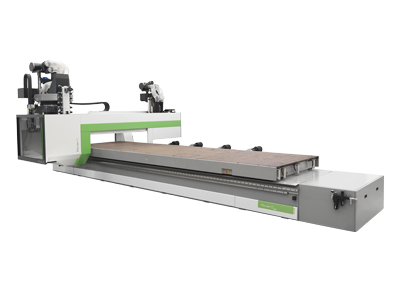

Rover A FT is the new high-performance CNC machining center for Nesting operations. Compact and efficient, with a gantry structure, the Rover A FT offers top-of-the-range technology and guarantees optimum precision in every machining operation.

COMPETITIVE CUSTOMIZATION

Made-to-measure turnkey factories, plus the integration of Biesse

Group solutions with complementary software and machinery,

with over 1000 systems installed worldwide.

Precision and reliability over time

All Biesse’s FT tables can adopt multi-zone technology, allowing the clamping area to be adapted to the panel format used.

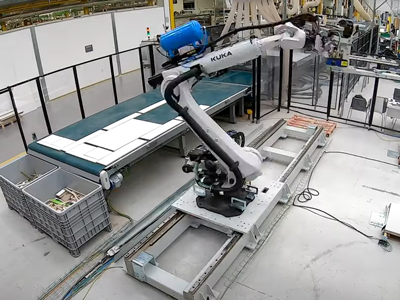

ROS

Integrated robot solutions.

Biesse offers its customers pragmatic solutions for factory automation.

ROS robotized solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

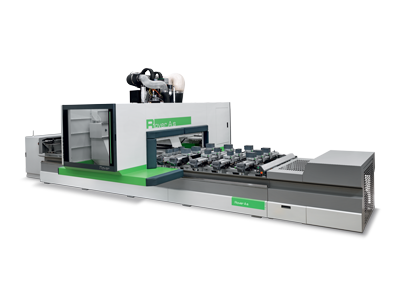

Maximum visibility of the working unit from any position

LED bar with 5 colours, in‑ dicating the machine status in real time, allowing the op‑ erator to check the machine status at any point.

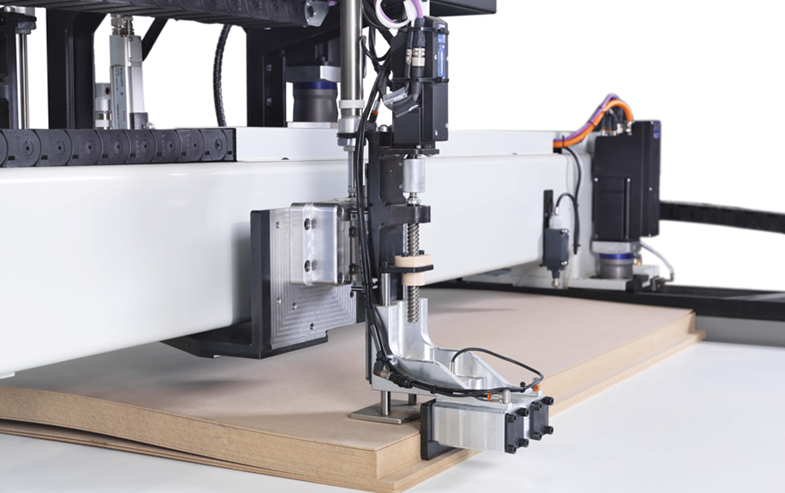

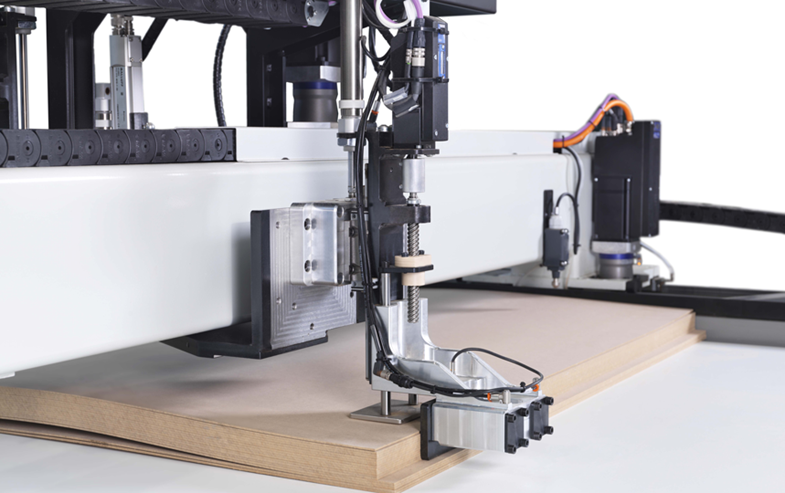

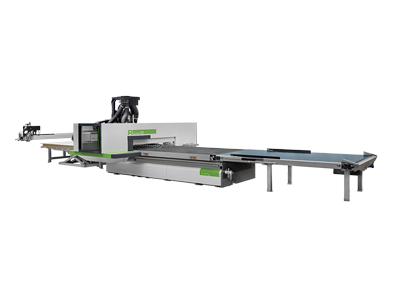

Roller press

Enables the processing of several overlapping panels of breathable material, up to 3 raw chipboard panels 18 mm thick.

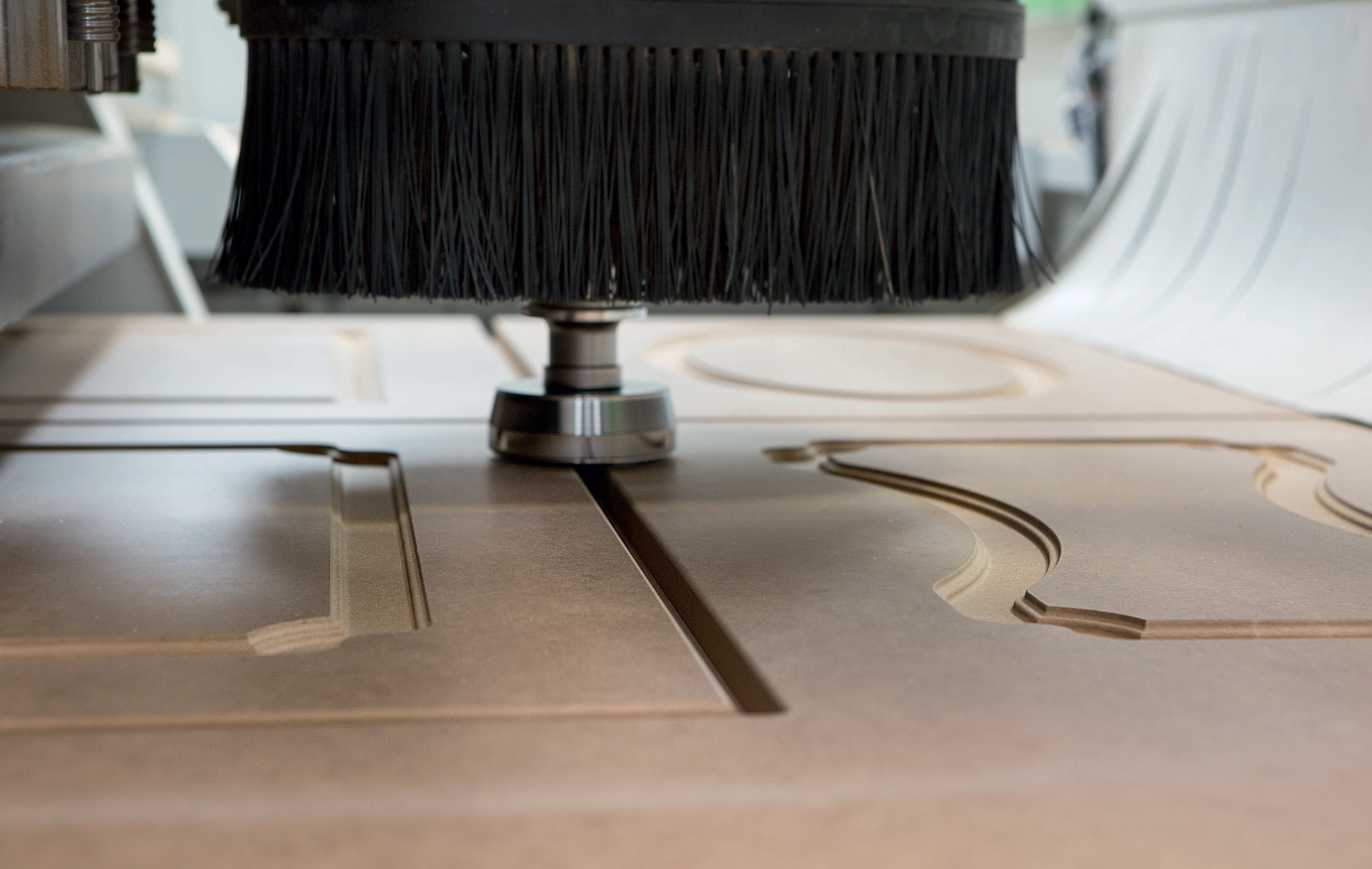

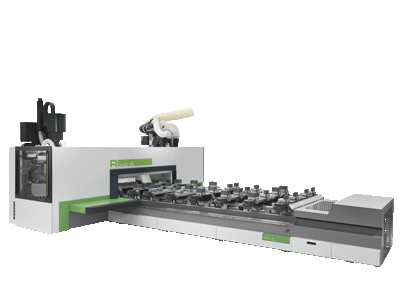

T-jet patented technology

T-JET is the solution patented by Biesse, for removing woodchips and dust during milling operations.

- LESS DUST AND FEWER WOODCHIPS ON THE TABLE, AVOIDING THE RISK OF DAMAGE TO THE SURFACE OF THE PANEL

- TOTAL CLEANING OF THE SIDE SURFACES OF THE PIECES

- EFFECTIVE SUCTION GUARANTEED EVEN AT HIGH FEED SPEEDS

- UNPRECEDENTED FINISHING QUALITY

.jpg)

Software for ROVER A FT

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

_400x300.png)