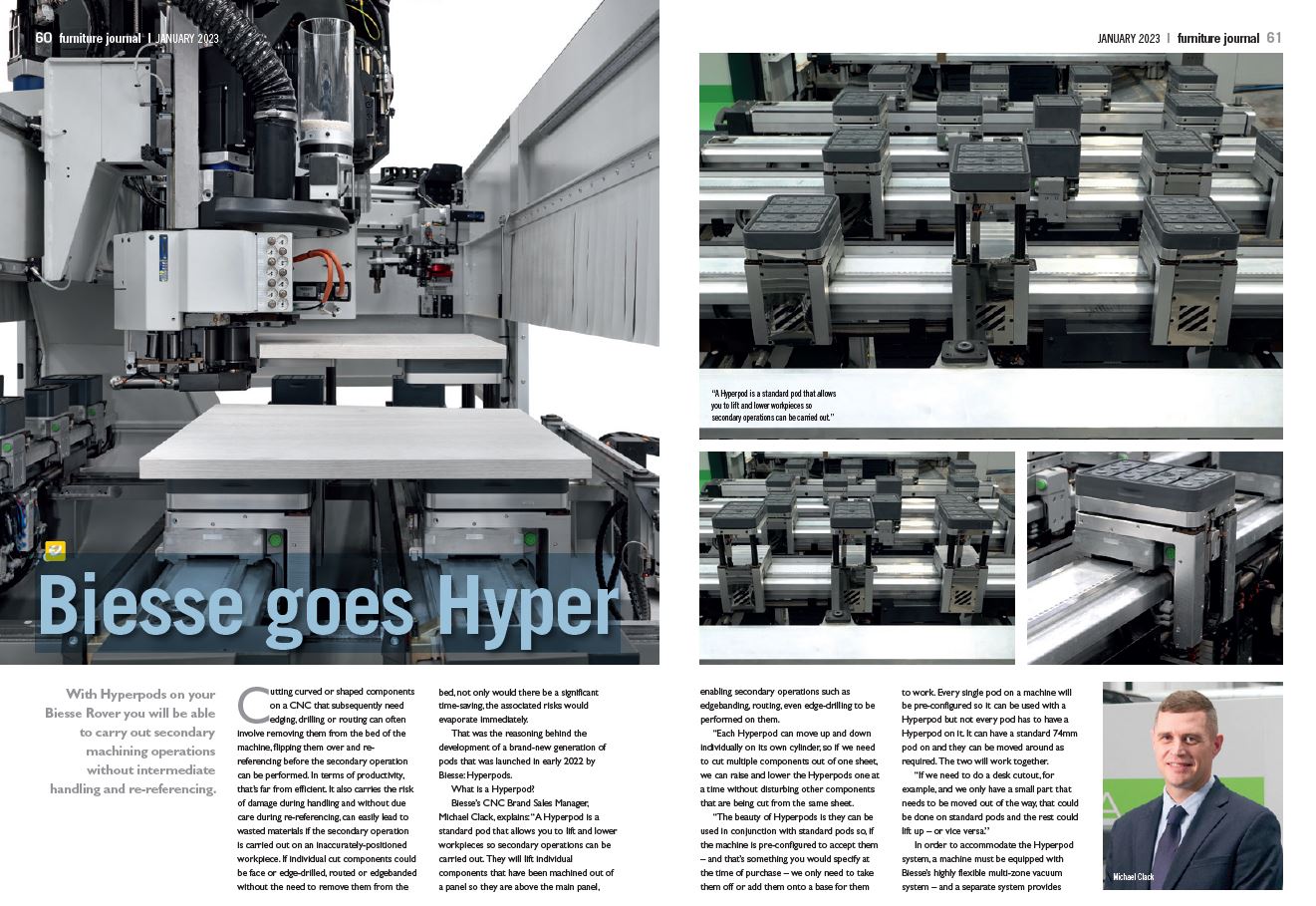

With Hyperpods on your Biesse Rover you will be able to carry out secondary machining operations without intermediate handling and re-referencing.

Cutting curved or shaped components on a CNC that subsequently need edging, drilling or routing can often involve removing them from the bed of the machine and re-referencing. In terms of productivity, that’s far from efficient and can easily lead to wasted materials if the secondary operation is carried out on an inaccurately-positioned workpiece.

If individual cut components could be face or edge-drilled, routed or edgebanded without the need to remove them from the bed, not only would there be significant timesaving, the associated risks would evaporate immediately.

That was the reasoning behind the development of a brand-new generation of pods that has been launched by Biesse called 'Hyperpods'.

A Hyperpod is a standard pod that allows you to lift and lower workpieces so secondary operations can be carried out.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.jpg)