We simplify your manufacturing process to make the potential of any material shine.

Classic Poly

Classic Poly apply finish coatings to a range of products for the kitchen and bathroom; living spaces and other architectural applications. From a modest factory in the Sydney suburb of Smithfield, George and his son Joey produce polyurethane and metallic finished products for what many in the industry feel is a difficult market. For George and Joey, using the right equipment is the only way to produce the quality their customers have come to expect, in the time they want it delivered. Their customers rely on Classic Poly and Classic Poly rely on Biesse Group. Only a year ago now they installed a Viet Opera 5 wide belt sanding machine and it’s transformed their business, and their lives.

George Al Khoury hails from Lebanon in the Middle East and like many hard-working migrants, he calls Australia home. Arriving in Australia in 1991 just after the civil conflict there ended, George set about to continue his trade in an environment he knew would reward him and his family, provided they put the effort into the industry. He tells us, “In Lebanon it was very difficult, there is no technology there and most of the work is done by hand. The civil war stopped many companies importing machinery, so we did most of our work on the bench.”

George started out in Australia at James Hardie where he worked for two and a half years, every day he would put in a full shift there and then drive to Botany where he would do his second job. He was building on his skills and learning how things were done in his new country. In 1994 he had enough saved and decided to start out on his own in Chipping Norton, near Liverpool. Like all new businesses it was tough going but he set about servicing his customers with good quality products that were delivered on-time. This way of business was hard to maintain, and he would often lose a job he couldn’t guarantee delivery on. This was the way it had to be; he would never promise a customer a delivery date that he knew he couldn’t meet.

One of George’s biggest concerns was his labour-intensive production. Mistakes were often made, and panels needed to be re-sprayed. Back then he only had a few people working for him and a day off for any of them meant George worked long into the evening to get the job finished. George admits, “I was very stressed. I worried about my customers; I didn’t want to let them down. Once a customer goes somewhere else, it’s very hard to get them back.” Twelve-hour days were fairly common for George, but his customers came first. He battled through and in 2002 moved to their present location in Smithfield with five employees.

In the new factory George was able to grow the business and soon he had more people working at the company. His stress levels didn’t improve now there were more people to look after. George says, “We were using hand-held, portable sanders to sand the panels before spraying. Imagine what your employees are feeling, using this equipment all day? And when we looked at the maintenance costs, we were shocked. We were spending at least three hundred dollars a week!” George was also struggling to produce work he could do for the right price, a price his customers would pay for the quality Classic Poly was able to produce. Something had to change.

In 2009 George’s son, Joey started to work in the factory part-time while he completed his studies. Joey began to understand the issues George was facing. The company was growing slowly and by 2016 had grown to ten people. Joey had started full-time the year before and was now taking an active role in management. Turnover had almost doubled in the previous six years, but the headaches continued. Three years ago, George said to Joey, “You know, wouldn’t it be good if we had a machine to do all this work?” Joey knew Biesse by reputation of their CNC processing machines he’d seen at their customers’, so he did some research and found out they produced a wide range of machines for many applications. They originally looked at the Viet Opera R but when they talked to Biesse they learnt the Viet Opera 5 was the best fit for their needs.

George was impressed with Biesse Group’s advice and was pleased to learn there was a machine in stock but like most small businesses, their primary concern was cost. Joey says, “When you buy a machine, especially one that to us, cost a lot of money, you always think about the price first. We were surprised that it wasn’t as much as we thought it would be, but for our business, it was a big step. But when the machine starts producing and we realised what it was doing for our business, you put the cost into perspective.” George adds, “On the day it was installed, just before we turned off the lights to go home, we ran a large panel through the machine and we just stood there and laughed.”

“We knew that panel would have taken almost fifteen minutes to sand by hand and the machine did it in under ten seconds. I was in love with the machine from that moment,” George said. Joey adds, “It takes two hours to sand twenty square metres of surface area, an average kitchen. The Viet Opera 5 can do it in ten minutes. When you understand what the technology can do for your business the price fades away and you look at the long-term benefits. Looking back, we would have paid twice as much, the Opera 5 is that good. It’s so important to our business, you can’t put a price on it.”

Other significant benefits Classic Poly gets from the Opera 5 is the consistent quality and guaranteed output. There’s no longer any repeat work; the quality can be guaranteed, and the delivery times can be forecast because they know exactly when the panels can be sent to the spray booths. George says, “It’s a big thing for our customers to know that the job we send them tomorrow is the same as the job we sent them last week. The machine brings new customers through the door. We save on labour, we save on maintenance, we save on materials and all these savings add up.” Classic Poly charge out their work for a fair price. George laments that other operators and under-charging and hurting the market. He says, “Our Opera 5 gives us a guaranteed finish that our competitors cannot match with low or no technology.” Joey adds, “The valued joinery shops respect the quality of our finishes and the finish comes directly from the Opera 5 sander.” Occasionally a customer will go somewhere else, but they usually come back for George and Joey service and honesty.

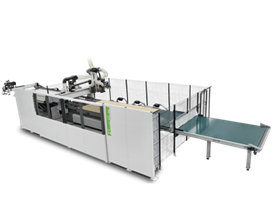

Classic Poly’s Biesse Opera 5 has four belts including cross sanding belts and electric pads with IPC controls. These limit the sanding time on the corners of the panel, preserving the most delicate portions of the panel's surface. The machine is quick too, something George and Joey think is a great benefit to them. “We have some big customers and they send us forty kitchens at a time, so we need to be able to process them fast without dropping the quality. The Opera 5 does this very well. We’ve never done a first job for a customer who hasn’t come back to us,” says Joey. “We’ve just had our first service; the machine is running beautifully, and we couldn’t be happier. We’ll move to a bigger factory one day and we’ll consider the Opera R, we think the Biesse sanders are that good,” adds George. The stress is gone, and George now has the time to concentrate on his artistic designer panels, a new range of products he hopes will continue the growth of the company he and Joey have put so much into.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil