We simplify your manufacturing process to make the potential of any material shine.

As a brand CROSA, originally CROSA & SASSERNÓ, dates back to 1897 and initially operated in the transportation sector; the business survived WWII by providing repairs and serving as a spare parts retailer and eventually shortened its name to C.R.O.S.A. (Commercio Ricambi Ogni Specie Auto). In 1962 Piero Sartore, father of current owners Giovanni and Francesca, acquired the historic brand. Over time Piero's three children joined the family-owned company, which expanded in new directions. Driven by attention to its staff and emphasis on growth, the company took the elevated skills it had developed over the years and its reputation for service in the vehicle spare parts sector and, at the dawn of the millennium, transitioned from being a parts dealer for cars to selling industrial components. In 2008 the company inaugurated a new machining operations department dedicated to plastics: a new business and the beginning of a long-term partnership with Biesse.

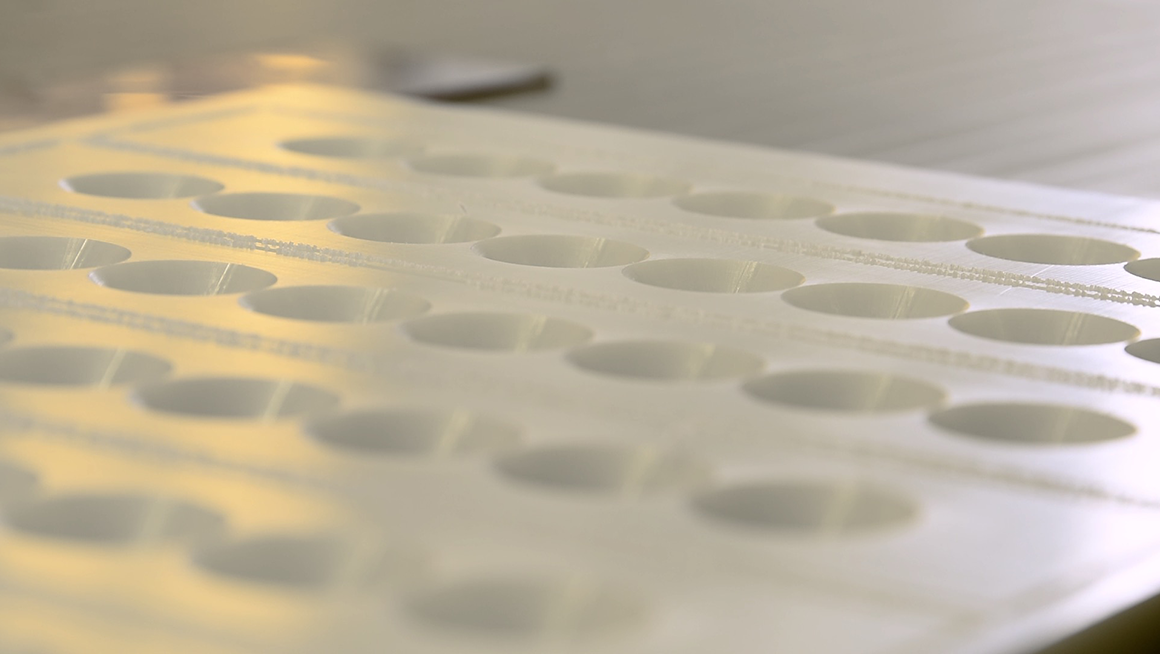

With over 15,000 customers across e-commerce and traditional sales channels, the Crosa warehouse provides more than 100,000 industrial spare parts and counts 32 customer service specialists. “These days CROSA mainly operates as a sales company, but that's not all we are. We also have a manufacturing unit dedicated to the production of plastics for the mechanical sector, and the food & beverage sector accounts for 90% of our activities," explained CROSA owner Giovanni Sartore. The company purchased two Biesse machines in 2018: a 3-axis machining centre, the Rover Plast A FT, and a 5-axis machining centre, the Materia CL. “Purchasing these two machines boosted our machining capabilities and helped us respond to the needs of our customers. The new technology also allowed us to create even more complex components”, Sartore continued.

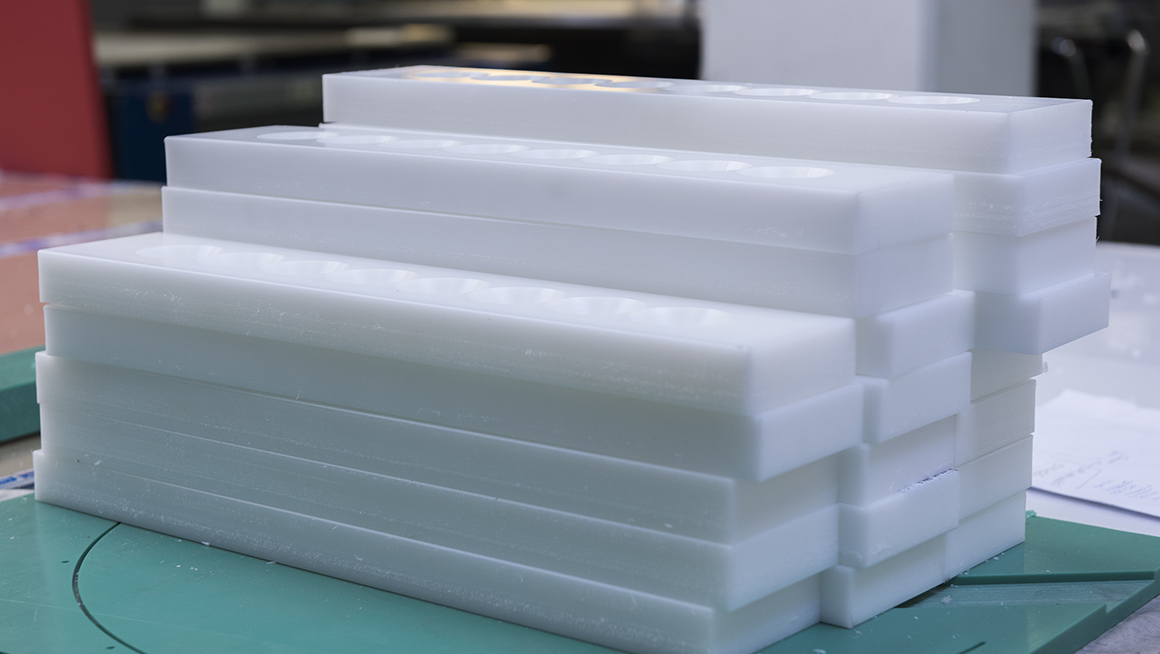

Precision machining, versatility and the capacity to cover every step in the creation of industrial technical components are some of the main advantages offered by the two Biesse machining centres. “We are able to handle the following machining operations for our customers: supplying the raw materials, supplying cut materials and supplying items processed from sheets of raw material. More specifically, thanks to the Rover Plast A FT we are able to achieve advanced nesting, while our pride and joy, the Materia CL, has opened us up to the processing of advanced materials, especially for the food sector”, explained Lorenzo, CROSA Production Manager. The company provides precise machining, milling and tapping for components used in the food & beverage sector. “Ever since we started using the Biesse machines, we have been able to offer higher quality and greater flexibility for our customers”, Lorenzo stated in closing. The industrial technical parts sector is full of challenges and opportunities: the production of complex industrial parts requires ultimate precision, a distinctive trait of Biesse technology. “I consider Biesse a partner for the coming future. The challenges will be increasingly complex, but I believe that we will have no trouble rising to the occasion together”, Sartore explained.

By opting for Biesse machining centres, we have introduced extremely innovative technology capable of taking on requests that entail the machining of parts with very complex shapes, sizes and materials, ensuring elevated precision, quality and reliability for our customers.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil