We simplify your manufacturing process to make the potential of any material shine.

We simplify your manufacturing process to make the potential of any material shine.

Biesse offers its customers pragmatic solutions for factory automation.

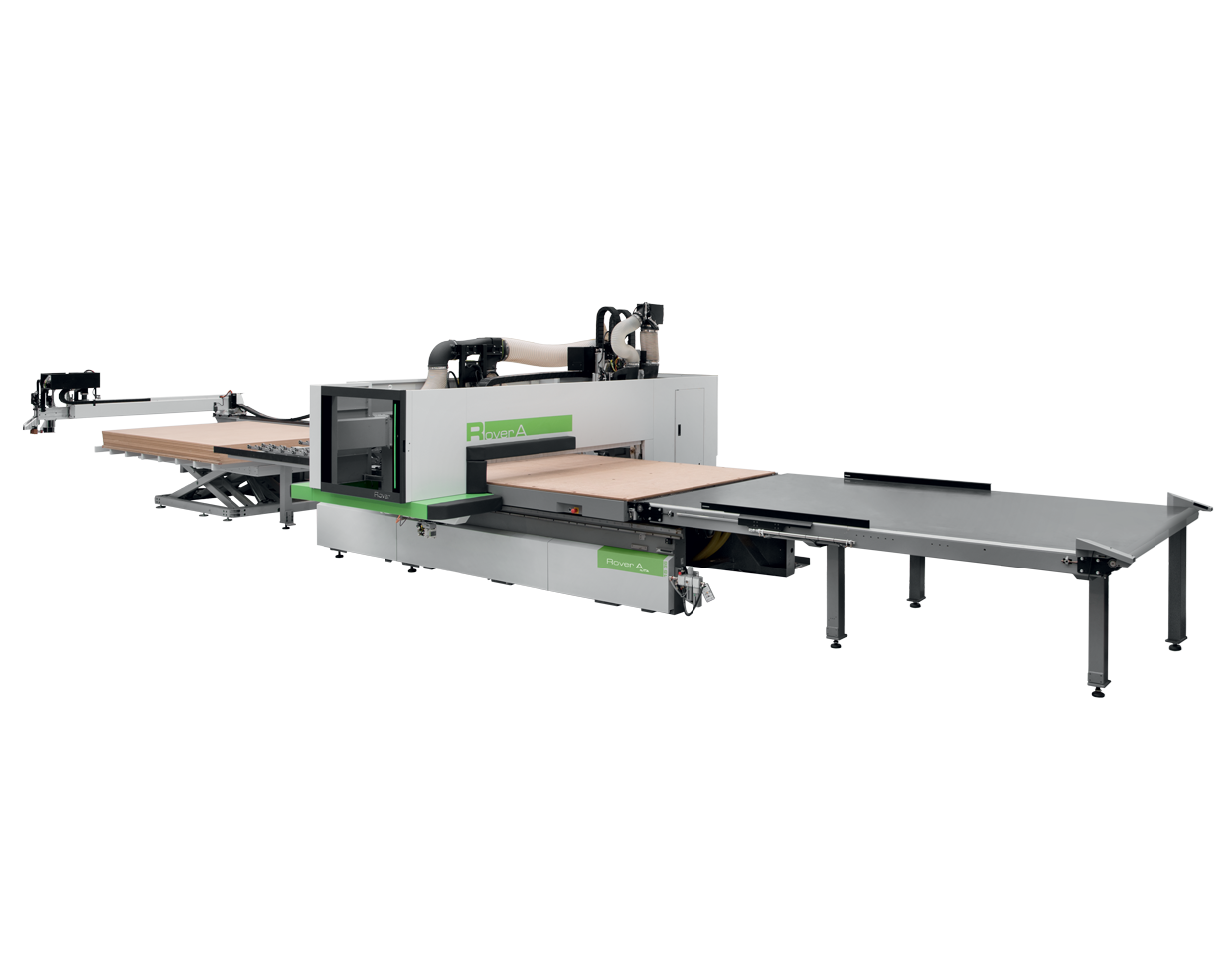

ROS robotised solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

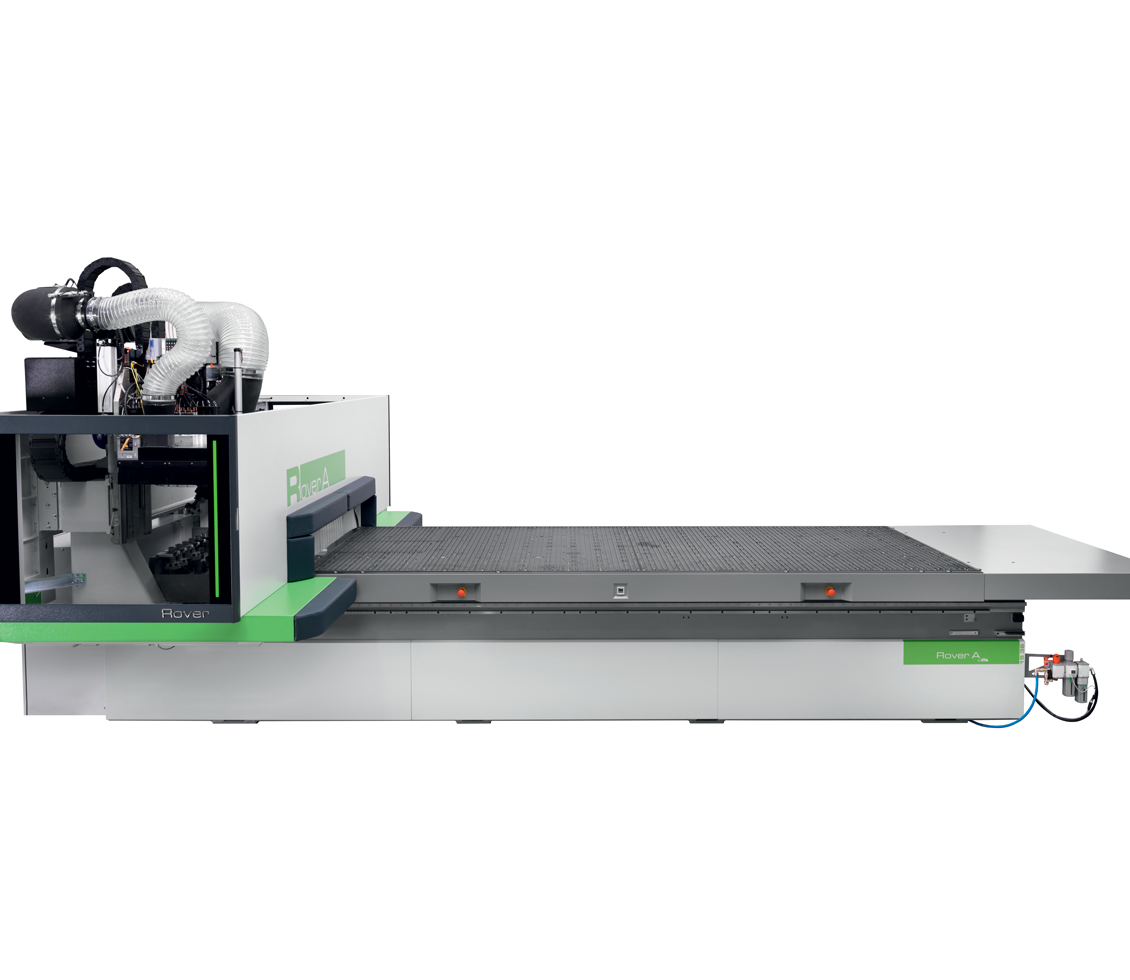

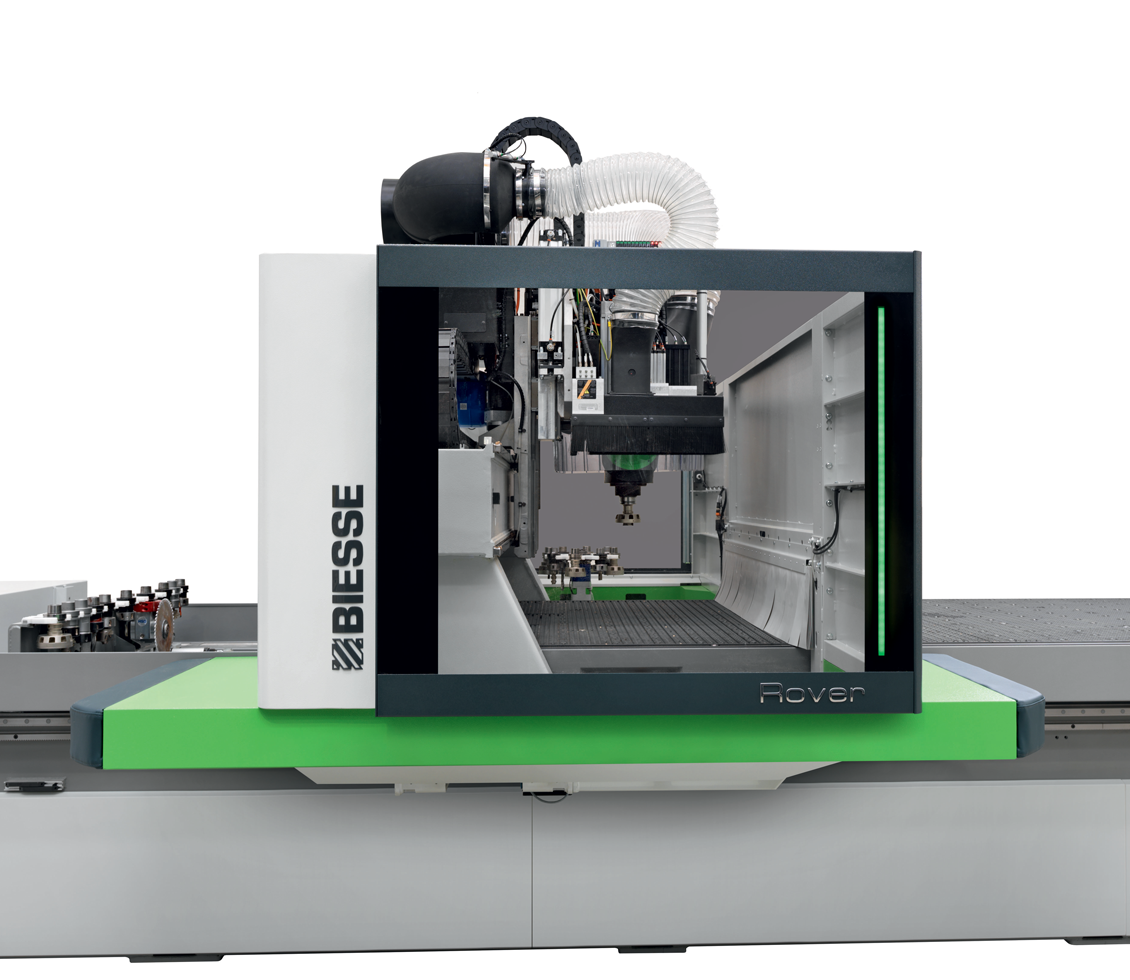

LED bar with 5 colours, in‑ dicating the machine status in real time, allowing the op‑ erator to check the machine status at any point.

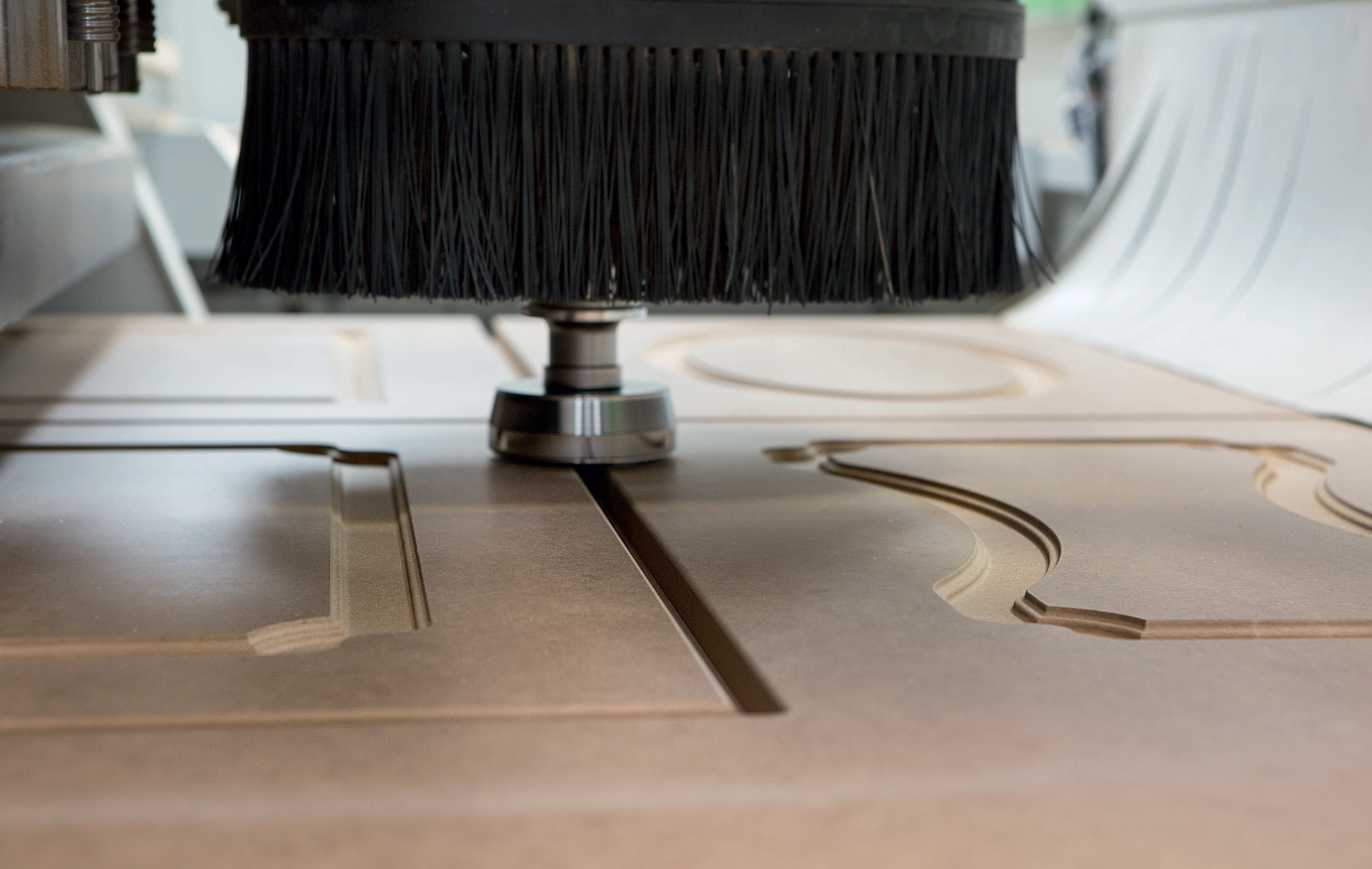

T-JET is the solution patented by Biesse, for removing woodchips and dust during milling operations.

- LESS DUST AND FEWER WOODCHIPS ON THE TABLE, AVOIDING THE RISK OF DAMAGE TO THE SURFACE OF THE PANEL

- TOTAL CLEANING OF THE SIDE SURFACES OF THE PIECES

- EFFECTIVE SUCTION GUARANTEED EVEN AT HIGH FEED SPEEDS

- UNPRECEDENTED FINISHING QUALITY

.jpg)