We simplify your manufacturing process to make the potential of any material shine.

HOME > Products >

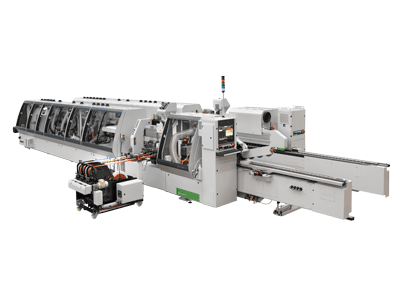

Single-sided edgebanding machines

STREAM A

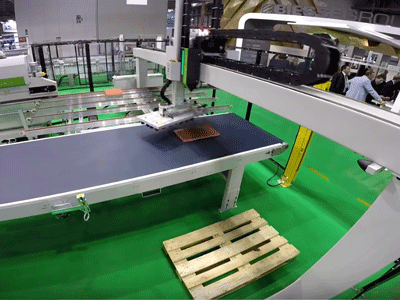

Automatic single-sided edgebanding machines

Tailor-made edgebanding

Stream A is the new range of automated single-sided edgebanding machines aimed at craftspeople and small enterprises who wish to increase their production capacity. It enables users to ramp up production up to 2 work shifts. It seamlessly adapt to any machining needs thanks to its configuration possibilities.

AIR FORCE SYSTEM

AirForce System is evolving, becoming ever more

efficient with reduced energy consumption and noise

levels.

AFS, available on Biesse edgebanding machines, is

based on the physical principle of convection. By using

a compressed hot air system, the edge bonds perfectly

with the panel guaranteeing resistance to water and

heat and an excellent long lasting quality finish.

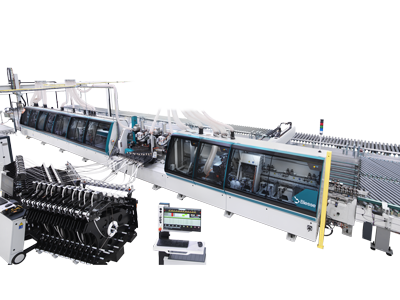

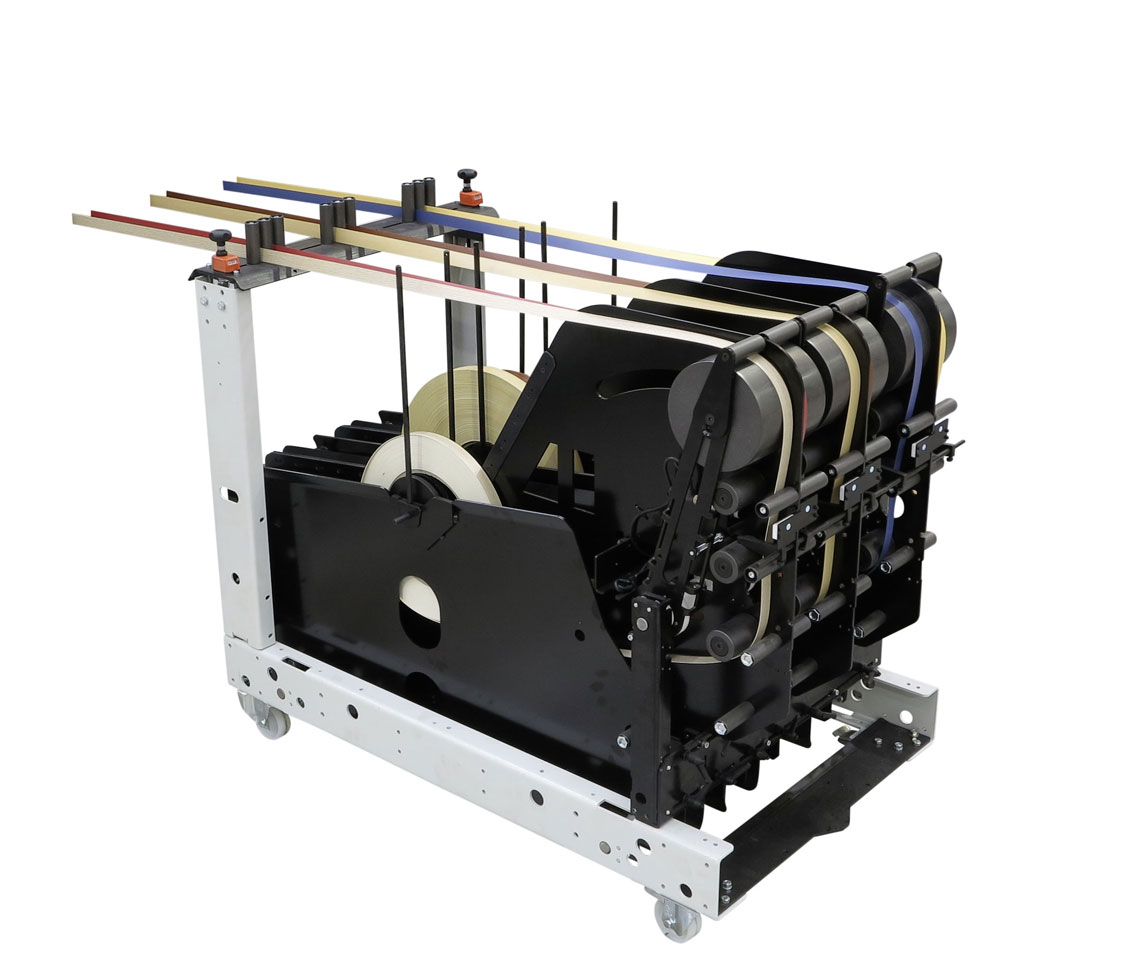

Edge warehouse

APPLICATION OF EDGEBANDING OF ANY SIZE

Greater flexibility and reduced tooling

time thanks to the 2- or 6 -place magazine

for automatic edge switchover in

real time.

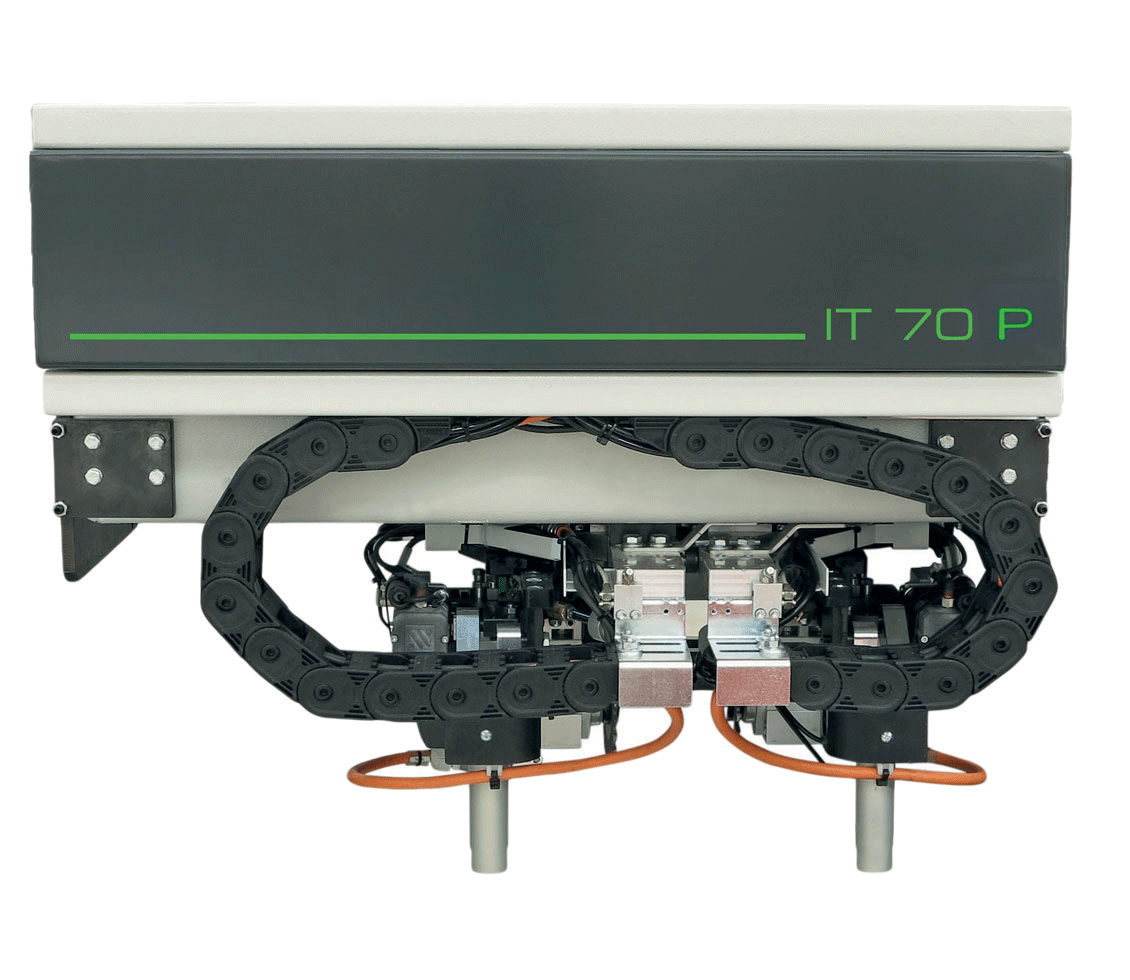

IT 70 P

Maximum visibility of machining operation

Linear edge trimming unit with stepper

movement. Solid wood machining up to

12 mm, speed up to 25 m/min.

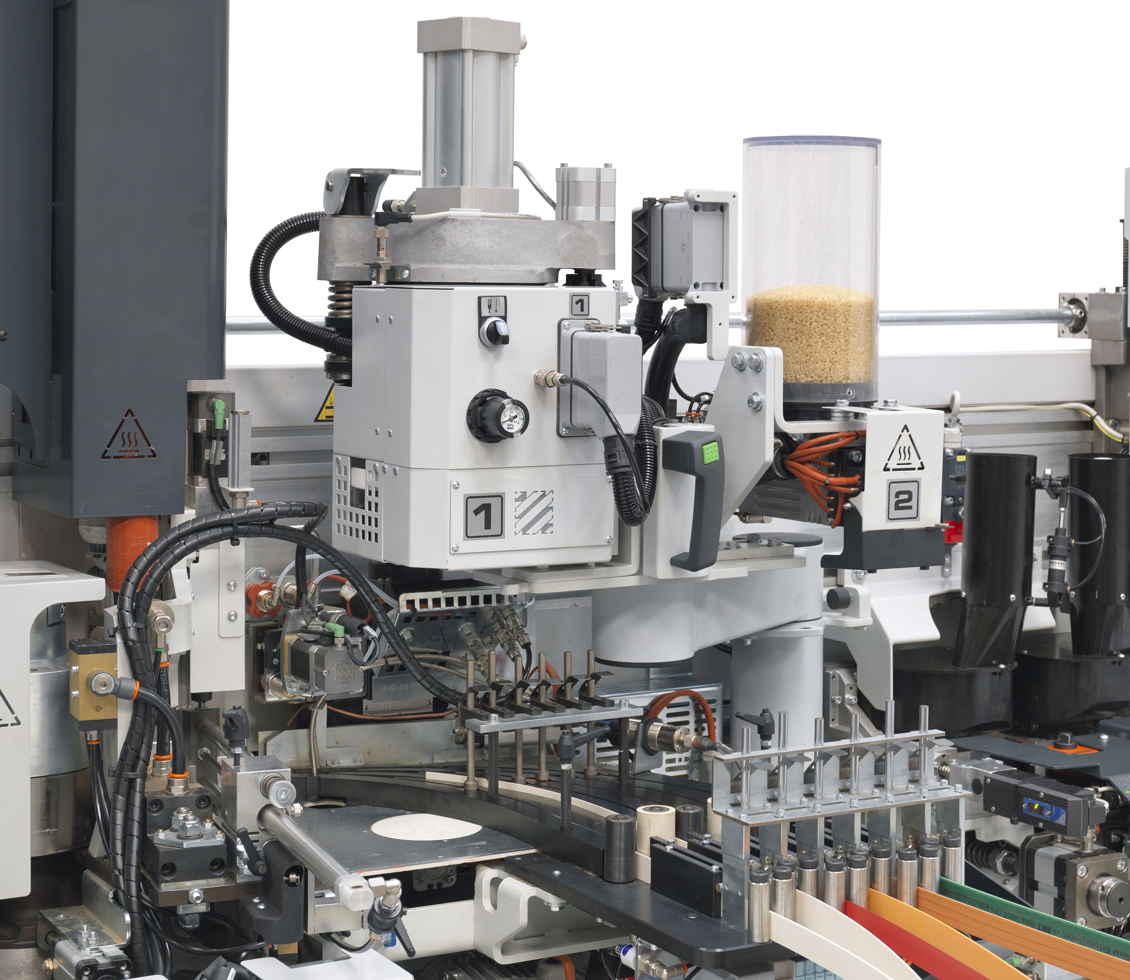

TWIN PRE-MELTERS

Maximum machining flexibility and efficiency

Thanks to the new gluing device designed for Stream A, the gluing

unit can now house 2 pre-melters that can be alternated

with just a few steps.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil