We simplify your manufacturing process to make the potential of any material shine.

Small step, big success.

A great game starts with a great move. Designed to deliver optimal results in an exceptionally compact solution with minimum working dimensions.

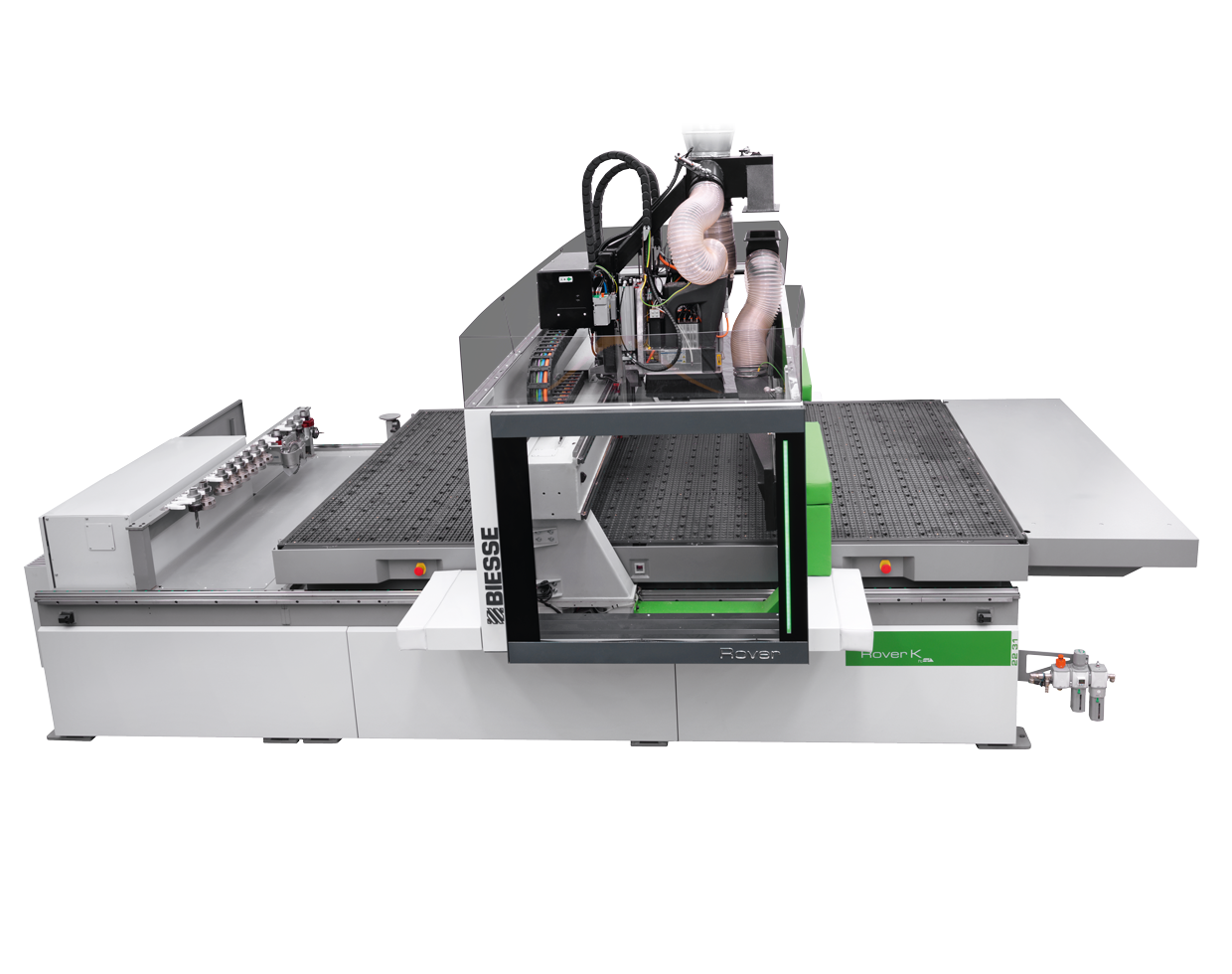

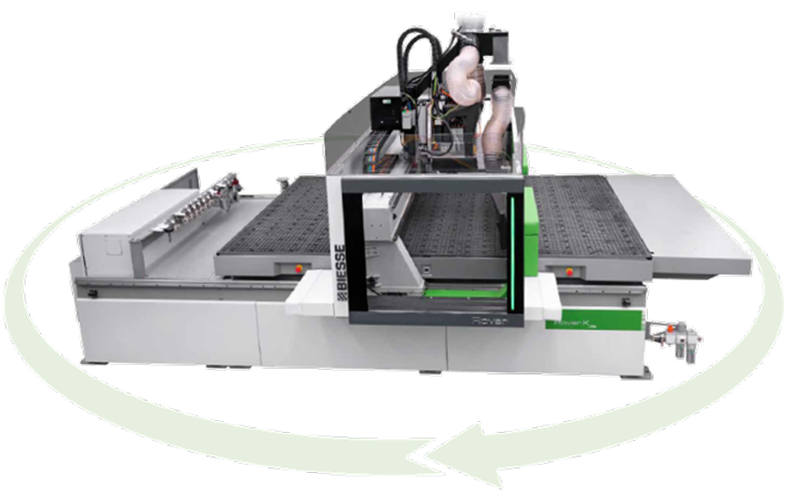

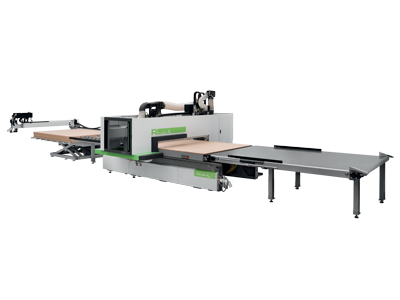

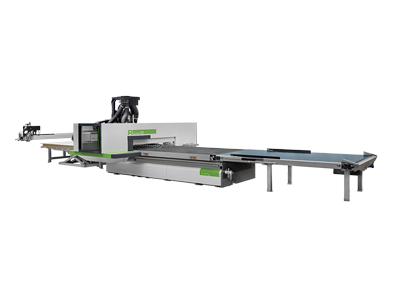

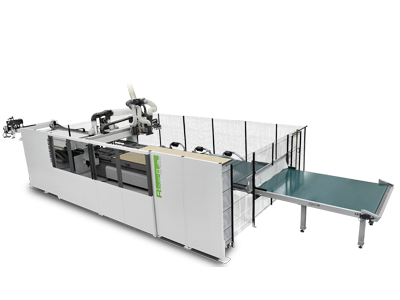

ROVER K FT

Easy and compact machining center for high quality NC nesting production.

Safety first

A dedicated safety control unit manages high reliable sensors to ensure the highest safety standard.

.png)

Simplification

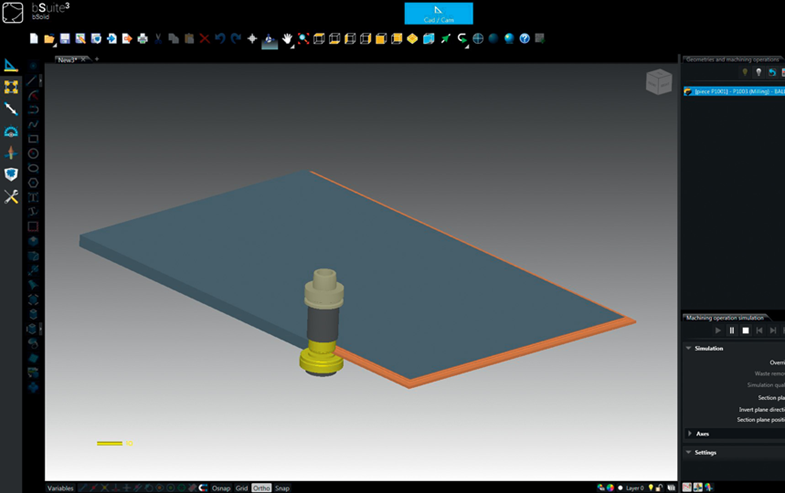

From CAD-CAM software straight to finished part, through an automated NC machine.The simulation feature allows to estimate production times and to improve production scheduling, keeping costs under control.

.png)

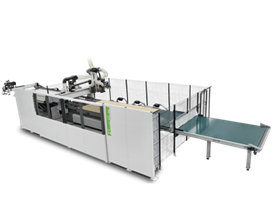

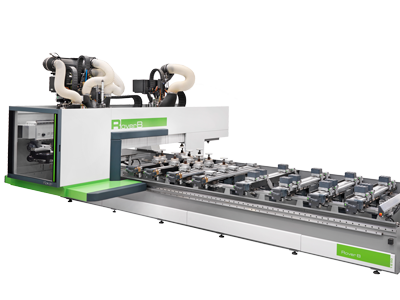

Flexible solution

Most of the processing of your furniture elements in a single automatic machine, with absolute precision and different sizes to fit to your needs.

.png)

Product quality

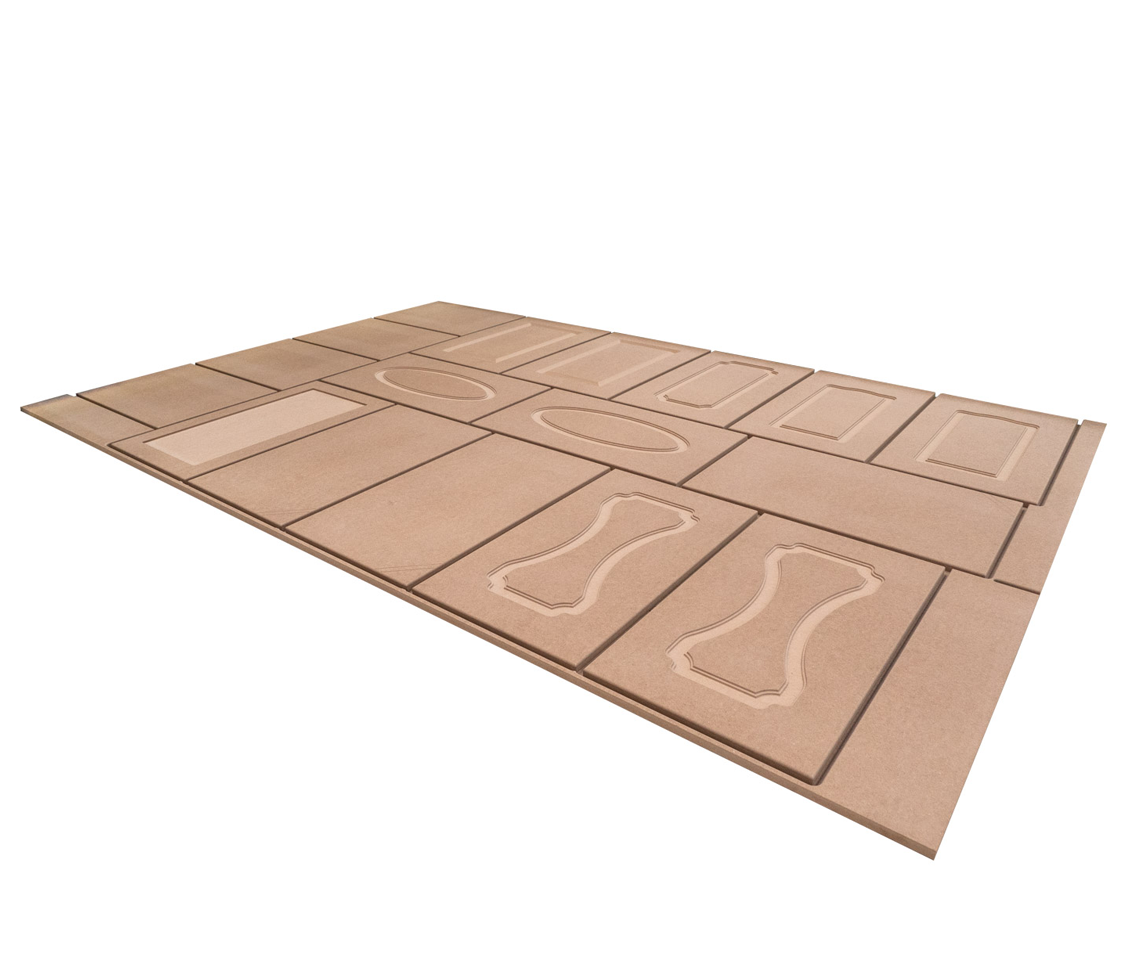

Finished parts produced with high precision, without dimensional errors, avoiding reworking detected during assembly phases. NC machining ensures highest repeatability on finished products.

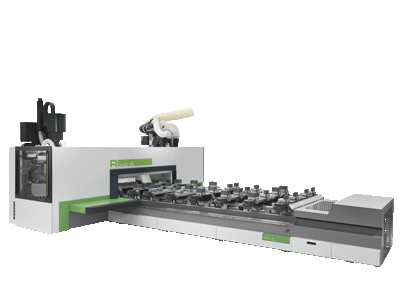

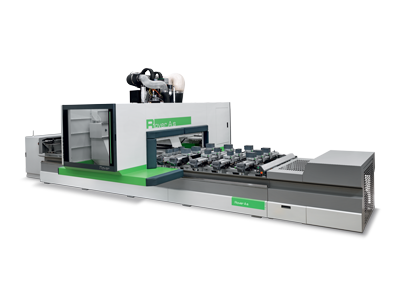

Reduced setup time

Tools and aggregates always available on machine to reduce setup time, for all type of machining operations. No operator intervention to change tool for different machinings.

Waste reduction

The optimized cutting path of the elements allows you to maximize the raw material, eliminate errors, make the result repeatable and reliable.

.png)

Integrated B_SOLID, CAD-CAM software

B_SOLID is available from design to nesting optimization, with all the features and additional modules available for upper class models.

Autonomy

The machine processes all elements for you, so you can focus on higher-value tasks.

.gif)

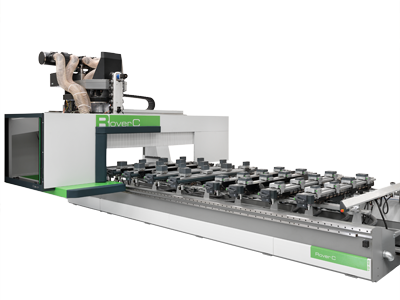

High-end quality

Rover K FT is available with components and element typical of upper-class models, to ensure high quality to manufacturing processes.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

.png)

.png)

.png)

.png)

_400x300.png)