Nous simplifions vos procédés de fabrication pour faire briller le potentiel de n'importe quel matériau.

Founded in the early 1980s, Carbon-Werke Weißgerber GmbH & Co KG now has more than 20 employees. Over the course of more than four decades, the company has grown from a supplier into a highly specialised high-tech manufacturer of carbon fibre products. The innovative company offers carbon panel and tube production as well as solutions and manufacturing technology for various industries including mechanical engineering, aerospace, automotive and medical. Carbon-Werke also fosters close relations with colleges, universities and research institutions to ensure know-how transfer to future generations and to stay on top of the latest scientific advances.

Franz Weißgerber, Head of Development at Carbon-Werke, has a wealth of experience in the production of carbon fibre components and their applications. His belief is to try to make the impossible possible for his company's customers. "In addition to our standard products, we manufacture parts for high-precision systems that require higher accuracy and low thermal expansion. Therefore, we rely on optimal equipment for our production." The state-of-the-art machinery was a great asset when a customer presented the carbon fibre specialists with a specific request: to manufacture a high-quality component with a curved surface and some additional features. This sounds deceptively simple but required a very fast and effective production process. Weißgerber contacted Biesse and together, they solved the task in a short time to the satisfaction of all involved.

Partners in carbon

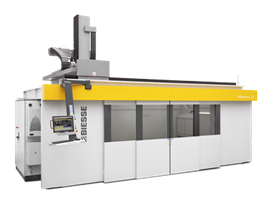

That was 13 years ago; since then, an intensive collaboration has developed. "Biesse has a high level of expertise in modern materials and much experience in the processing of a wide range of materials. The required production steps were mapped with one of their 5-axis Primus waterjet cutting machines, and ever since then, we have been in close contact," says Weißgerber. That both partners appreciate the cooperation is confirmed by Andreas Lohse, Director Technology Applications and Product Manager for the wood, stone, glass and advanced materials divisions at Biesse. He has been working with Carbon-Werke from the very first enquiry. "The most valuable part of this intensive partnership is that both parties grow with it. We have enhanced our machines based on feedback from Carbon-Werke. Our joint experience has directly influenced the design and revision of the following Primus generations."

Future-proof technology

All Biesse customers benefit from the experience gained: Primus, with its waterjet system, has been specially designed to meet the needs of companies that require maximum versatility in the processing of plastics, composites, non-metallic alloys, titanium, aluminium and other metals and is ideal for cutting various materials and any shape, no matter how complex – precisely and with high-quality, sharp edges.

The state-of-the-art machine also includes simple but effective fastening and adjustment systems, which minimise set-up times and, in combination with the other features, contribute to the optimisation of cutting costs. Biesse provides a comprehensive range of accessories and individual special equipment to meet all customer needs. The Primus cutting system can be programmed with maximum flexibility thanks to the fully interpolating five-axis cutting head employing the patented Biesse system with an endless rotating C axis. It allows for the highest level of customisation, as its technology adapts to the evolution of materials and extremely versatile application requirements.

Outlook

Carbon-Werke is successful – so successful that the production and the shop floor will have to be expanded. At the heart of the planned extension is a new, 12-metre-long waterjet cutting machine. Of course, it will be a Primus from Biesse. "The series' noted advantages such as light weight and high rigidity have been even further enhanced in the new generation. Along with the three Primus models that have been reliably serving us for years, we will have higher capacities – and we will be able to create far more complex objects," says Weißgerber, looking forward to future tasks.

Biesse has a high level of expertise in modern materials and a lot of experience in processing and processing a wide variety of materials.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil