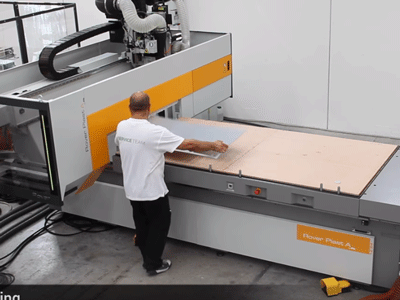

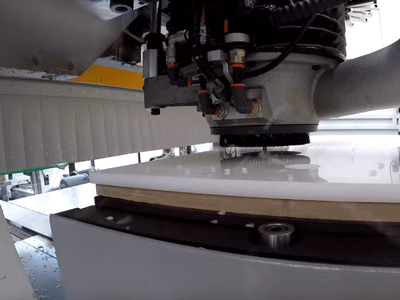

Rover Plast A FT - Alucobond Routing

See the Rover Plast A processing an alucobond component with its high speed electrospindle which grants a fast feedrate and a perfect finishing quality.

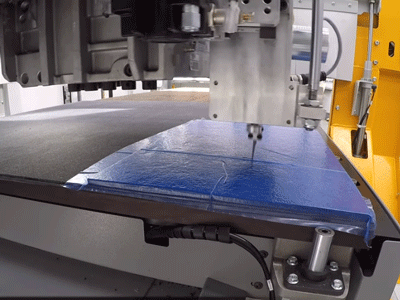

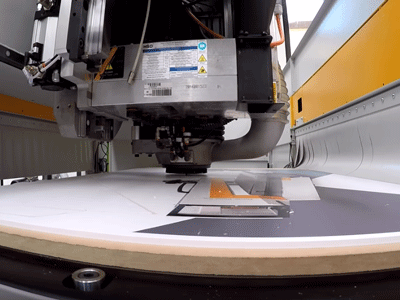

Rover Plast A FT - Felt Puzzle Cutting

See the Rover Plast A Cutting a felt Puzzle with its high speed oscillating knife.

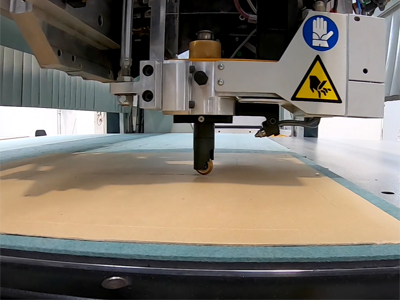

Rover Plast A FT - Foam Bottle Case

See the Rover Plast A Cutting and Pocketing a Foam bottle holder with its high speed electrospindle which grants a fast feedrate and a perfect finishing quality.

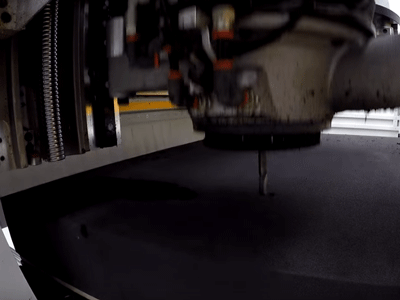

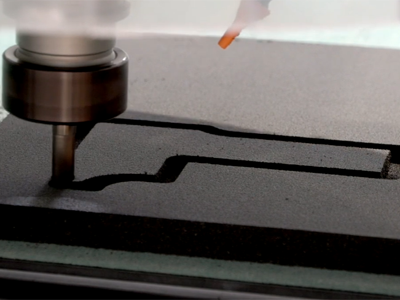

Rover Plast A FT - Foam Pattern Cutting

See the Rover Plast A Cutting a Foam component with its high speed oscillating knife.

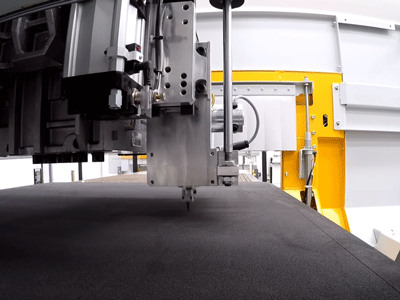

Rover Plast A FT - Honeycomb Paperboard Cutting

See the Rover Plast A Cutting a honeycomb paperboard component with its high speed oscillating knife.

Rover Plast A FT - Nylon Component Routing

See the Rover Plast A Cutting and Engraving a nylon component with its high speed electrospindle which grants a fast feedrate and a perfect finishing quality.

Rover Plast A FT - PVC Banner Routing

See the Rover Plast A routing an PVC banner with its high speed electrospindle which grants a fast feedrate and a perfect finishing quality.

Rover Plast A FT - Acrylic Routing

See the Rover Plast A Cutting and Engraving an acrylic component with its high speed electrospindle which grants a fast feedrate and a perfect finishing quality.

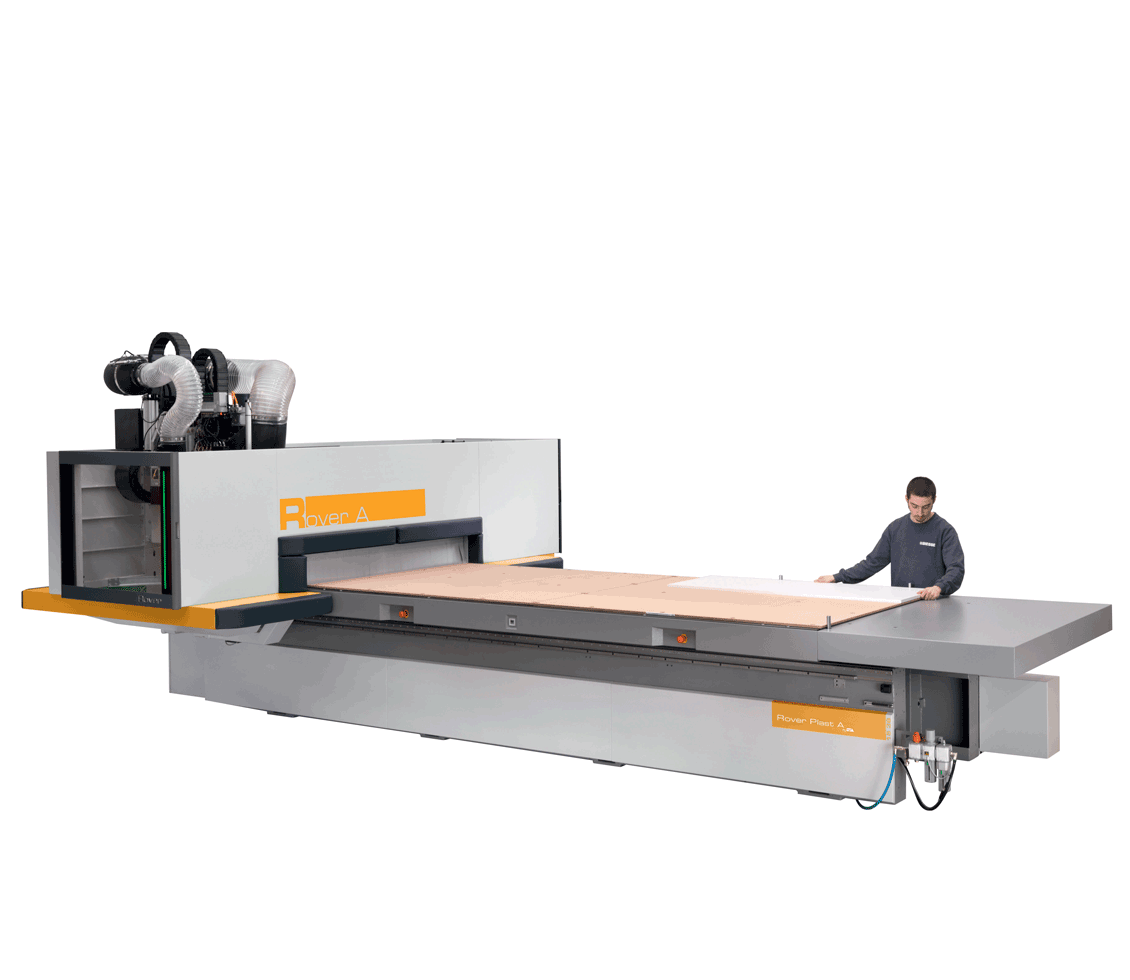

Rover Plast - Machine Features

All the experience and DNA of BIESSE is brought to the Advanced Materials market segment to help customers with the most effective and technological solutions. Discover Rover Plast A FT, the 5-axis machining center dedicated to the processing of technological materials typically used in the following sectors: automotive, technical articles, construction and energy.

Rover Plast - Combined Routing and Cutting Machinings

Rover Plast A FT is the 5-axis machining center dedicated to the processing processing of technopolymers, composite materials, rubbers and foams. The only solution for performing routing and cutting machining on technological materials.

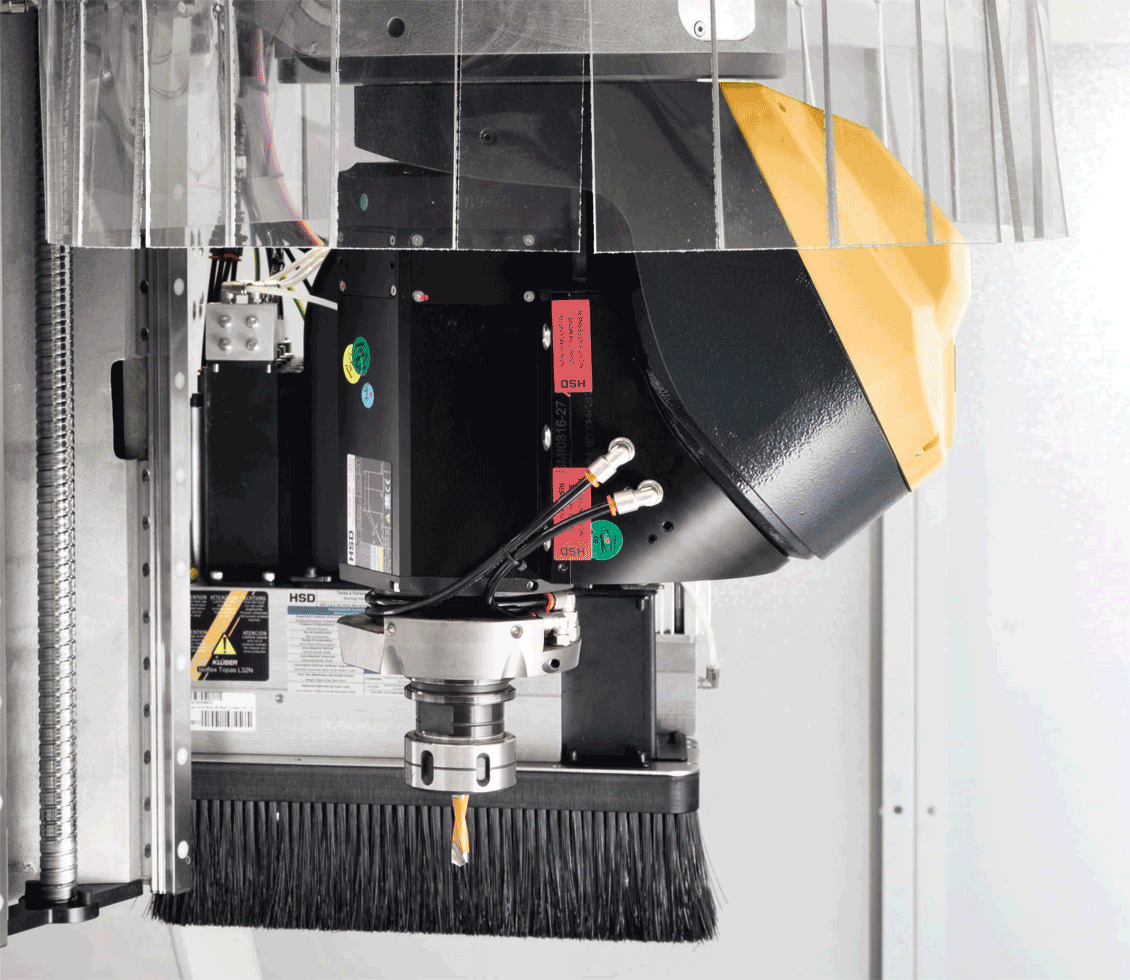

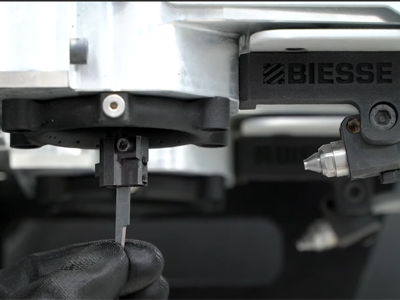

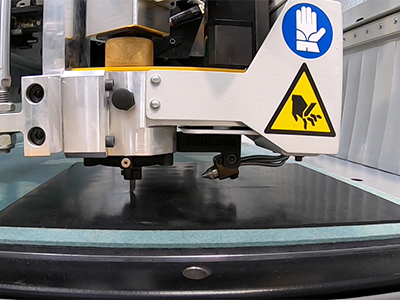

CNC Rover Plast - Knife System Change

Extremely quick and simple blade changes. The operator can make a blade change in just a few steps, limiting the machine downtime.

CNC Rover Plast - Creasing Wheel Application

The precision and quality typical of Rover's technology support the perfect execution of all standard machining center processing operations. Rover Plast can be equipped with cutting units with blades of different types.

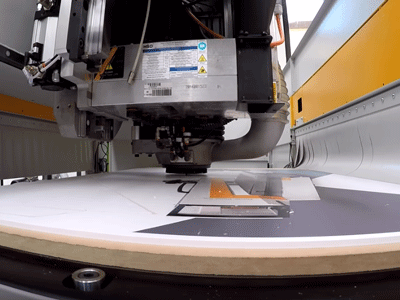

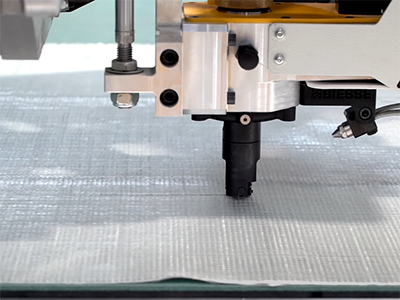

CNC Rover Plast - Glass Fibre Cut

Rover Plast is the 5-axis machining center for processing the most common materials requested by the market: PE, PP, PVC and PMMA, but also compounds, technopolymers, rubber, extrusions and foams. Watch now how the machine cuts the glass fibre.

CNC Rover Plast - Kiss Cut Application

The Rover Plast is the ideal solution for machining materials of different formats, size, thickness and density. The extremely rigid and well-balanced structure is designed to withstand notable machining strain and ensure high levels of precision

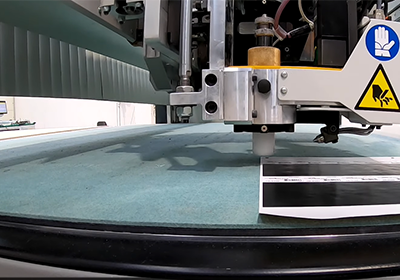

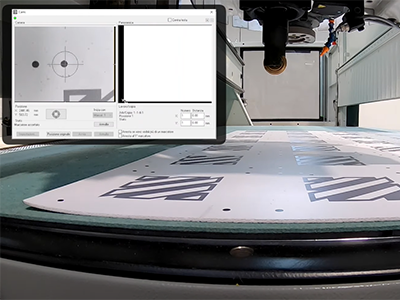

CNC Rover Plast - Machining of Printed Panel With Markers Recognition

Rover Plast can be equipped with cutting units with different types of blade and geometry, to meet every type of requirement. The cutting unit can also house the video camera for the optical recognition of the print markers, which is a particularly useful feature in the graphic sector.

CNC Rover Plast - Machining Rubber Gasket With Long Stroke Cutting Unit

The precision and quality typical of Rover's technology support the perfect execution of all standard machining center processing operations. Watch a rubber gasket machining in our Rover Plast, processed with the cutting unit.