HOME > Products >

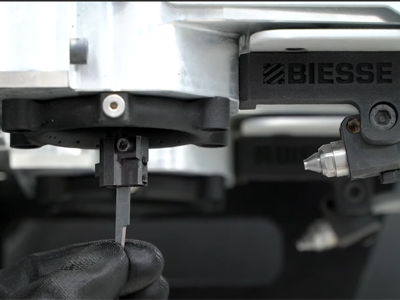

CNC - Plast

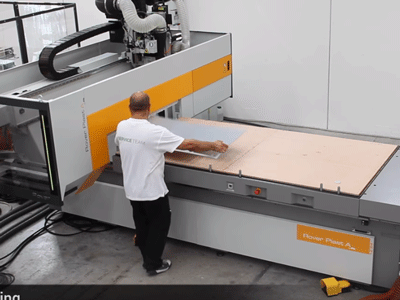

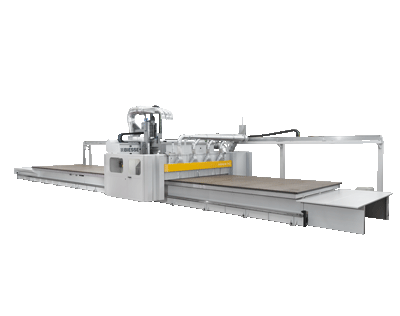

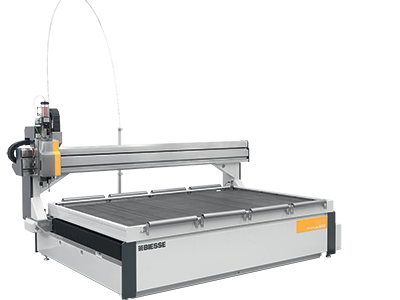

ROVER PLAST A FT

CNC plastic machining center

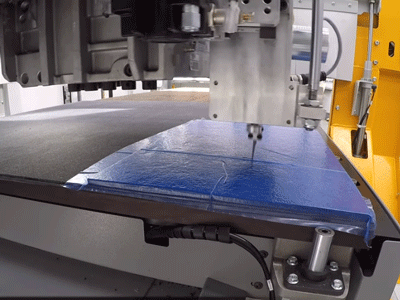

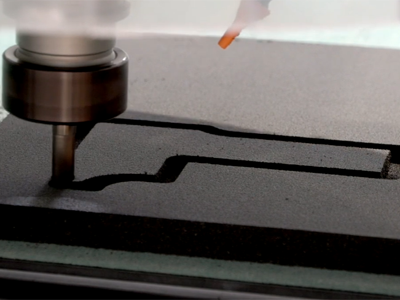

Technologies for the processing of technopolymers, composite materials, rubbers and foams.

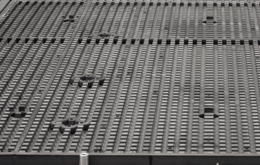

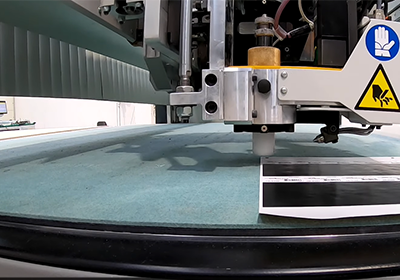

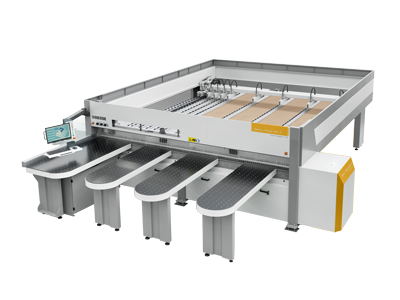

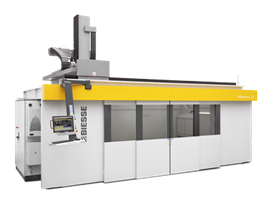

Biesse offers two types

of work surfaces, to satisfy the different

application and processing needs

of the client: HFT and FT PLUS.

RELIABLE TECHNOLOGY

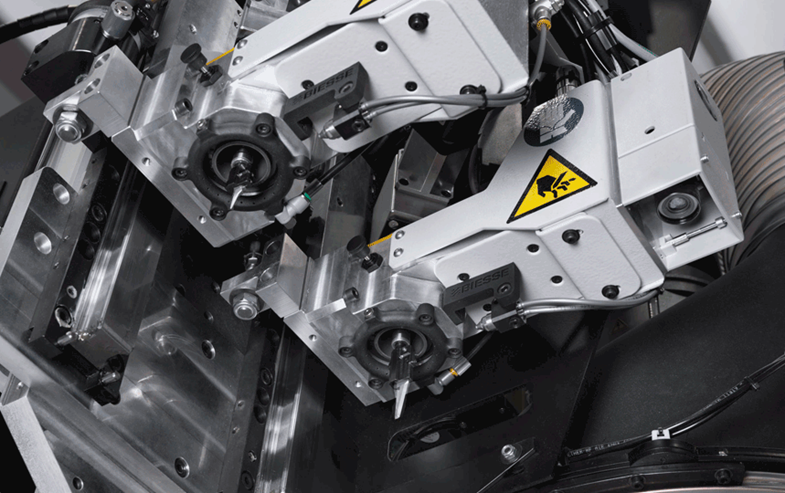

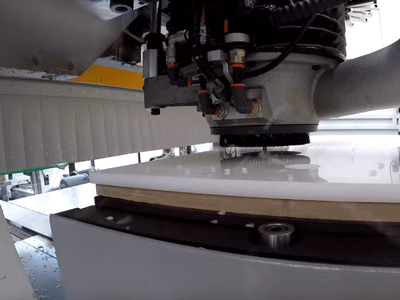

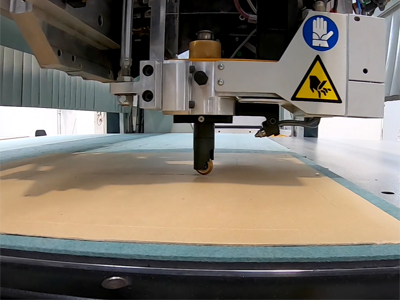

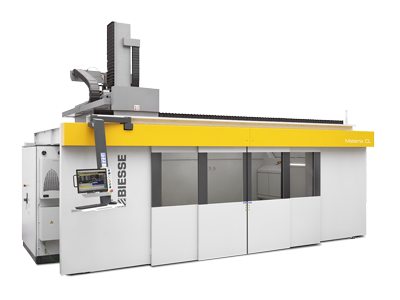

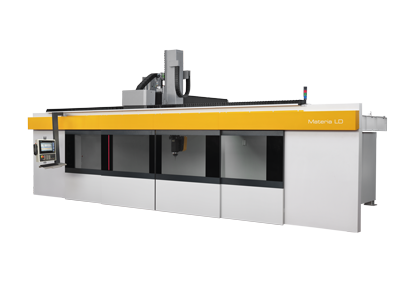

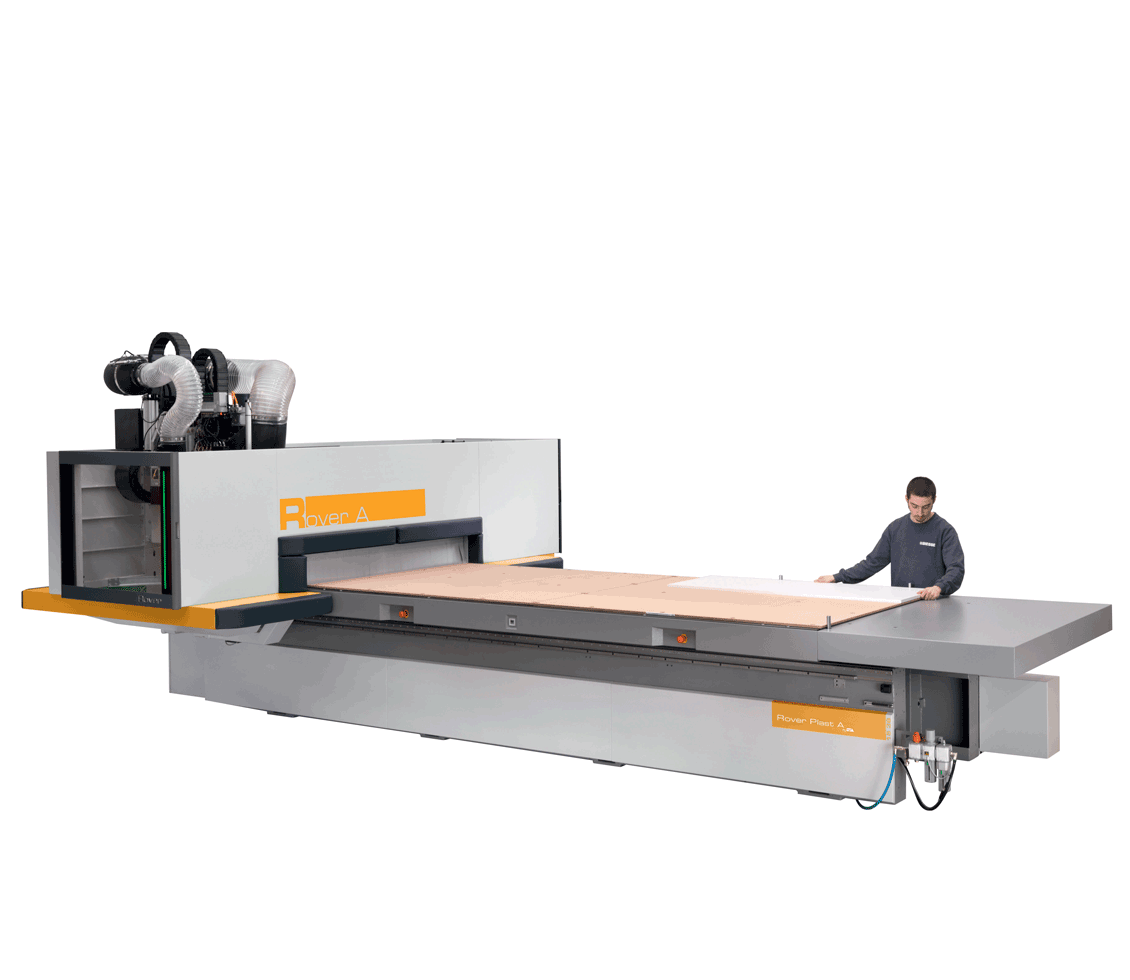

Rover Plast A FT is the 5-axis machining center dedicated to the processing of technological materials typically used in the following sectors: automotive, technical articles, construction and energy.

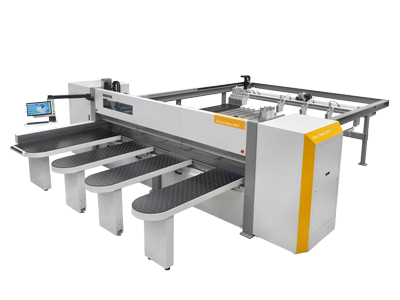

Performance without limits

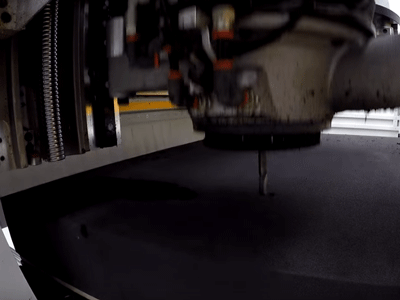

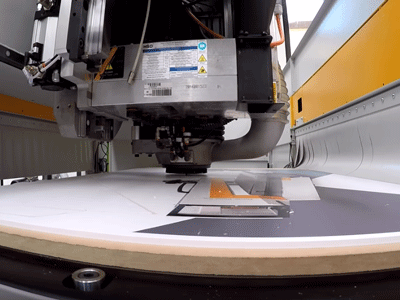

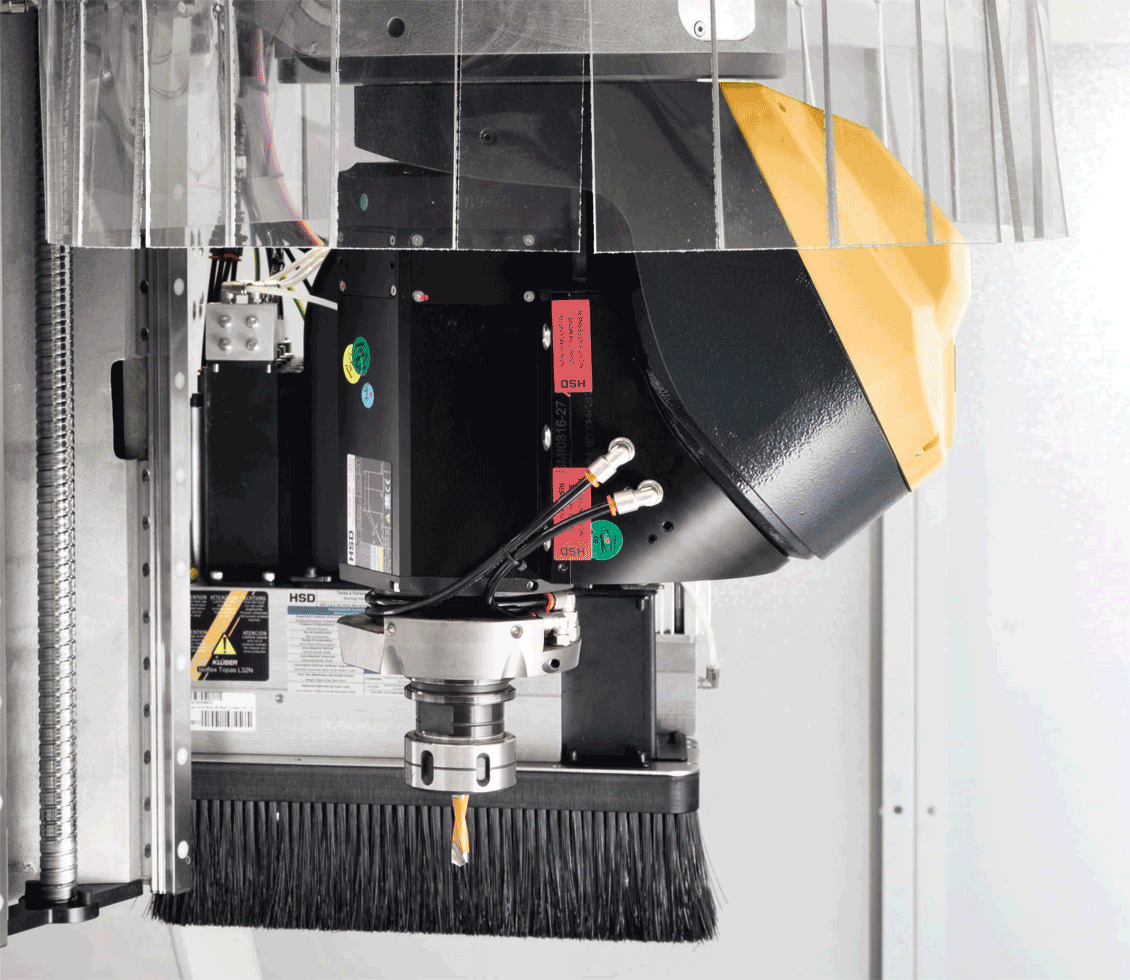

The only solution for performing milling and cutting

operations on technological materials.

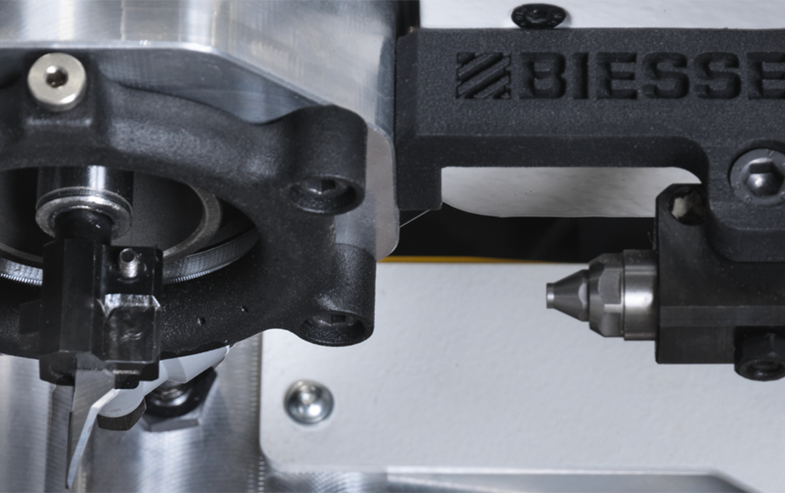

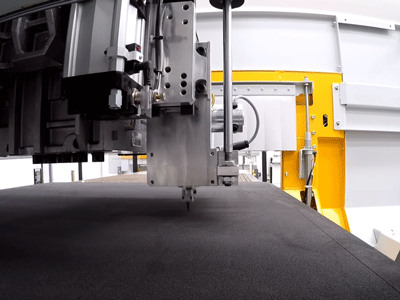

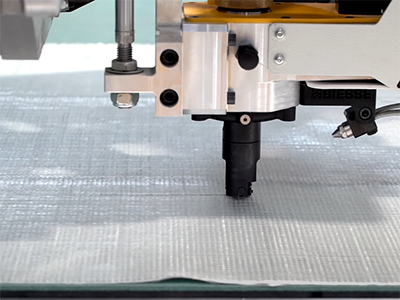

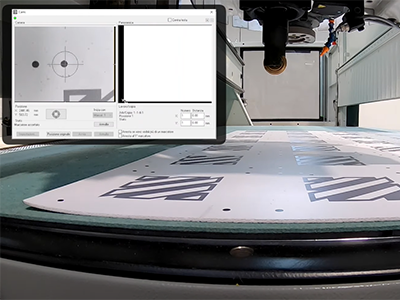

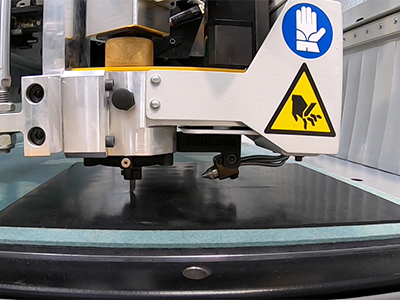

The tangential/oscillating blade combined with the video camera for the optical recognition of the print markers gives the machine greater versatility to adapt to every market need.

The precision and quality typical of Rover's

technology support the perfect execution of all

standard machining center processing operations.

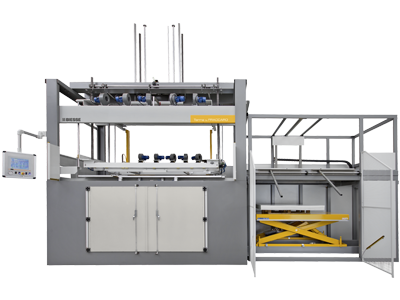

Long term precision and reliability

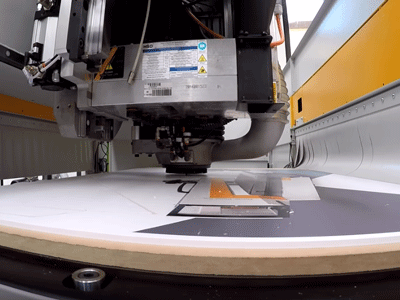

Rover Plast A FT in full bumper version is one of the most compact solutions on the market. It is designed to best adapt to the production space. It allows the operator to always access the machine from all sides, in total safety and without obstacles on the ground.

Effective dust extraction systems

The processing of technological materials requires complete and constant cleaning of the work area to achieve high-quality standards. Biesse offers various dust and chip extraction systems.

Software for ROVER PLAST A FT

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil