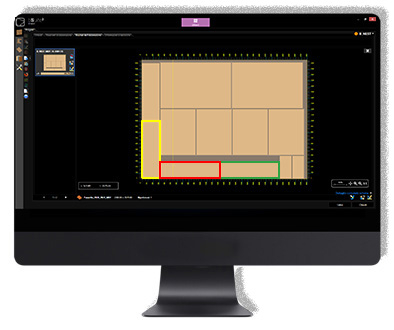

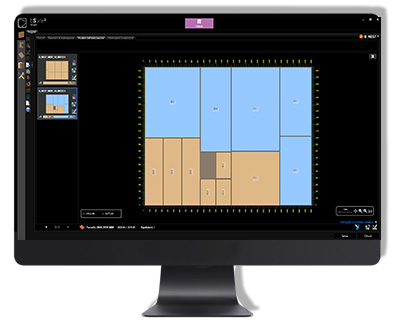

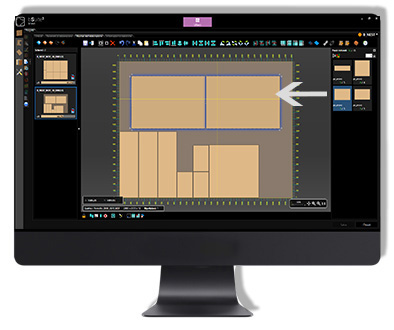

STANDARD ALGORITHM

This is the nesting mode typically used for rectangular pieces. Next, they are cut by the milling cutter, which follows the contours of each individual piece, guaranteeing an excellent finish.

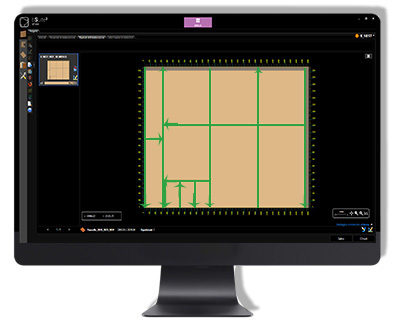

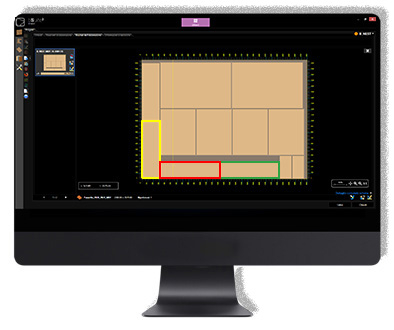

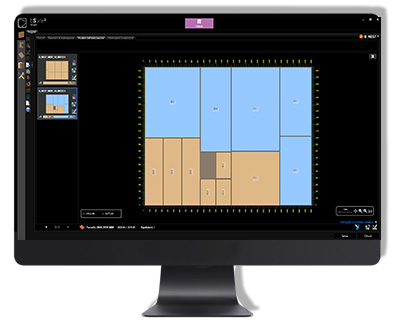

COMMON CUT ALGORITHM

This function was designed for cutting rectangular pieces that are generally of different sizes. Machining time is reduced by positioning the pieces so that the mill only needs to pass once between pieces that have sides, or part of a side, in common.

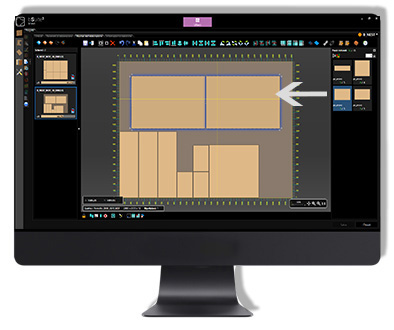

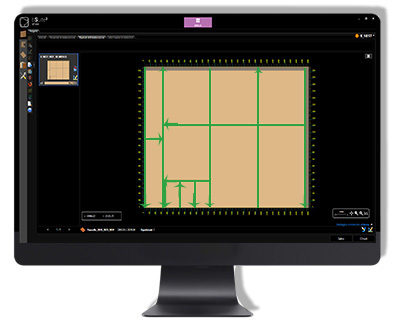

GUILLOTINE CUT ALGORITHM

This solution recreates the tool path of a panel saw. The time it take to execute the programme is reduced since the longitudinal and transverse milling of the sheet simulates the behaviour of a panel saw.

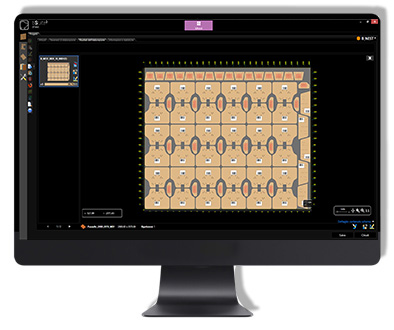

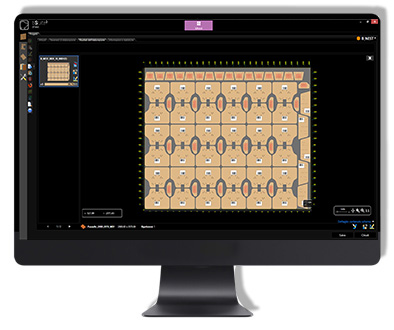

FREE SHAPE ALGORITHM

This algorithm allows for optimal nesting, with minimal waste, of non-rectangular pieces (Free Shapes).

The Free Shape algorithm has additional advanced features to improve the positioning of the pieces.

- Cluster Management + Grid Fit: this option allows for the pairing of pieces whose shapes are complementary (reducing the area occupied by the pieces) and then optimising the nesting of such groups (Clusters) by means of a virtual grid.

- Dynamic selection of corners and directions: this feature uses more computing power to generate a higher number of combinations before determining which results are the most efficient and selecting the best option.

- Identifying and filling apertures: for filling in the areas inside the pieces with slotting.

GRAPHIC EDITOR FOR THE NESTING RESULTS

This optional feature allows the user to make manual changes (moving, adding or removing pieces) to the nesting results produced thanks to an intuitive and easy to use environment.

GRAIN MATCHING AND ASSEMBLY MANAGEMENT

This further optional module allows for the nesting of “groups” of pieces. It is commonly used by those who need to maintain the continuity of the grain across pieces or, more generally, by any user who wishes to nest groups of pieces whose spatial relation to each other must remain unaltered.

WASTE MANAGEMENT

Thanks to the Waste Management module unused portions of the sheet can be automatically recovered to produce scraps for subsequent use.

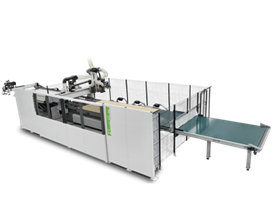

B_NEST: numerous options for optimising your manufacturing process.

For more information contact your local service representative!

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil