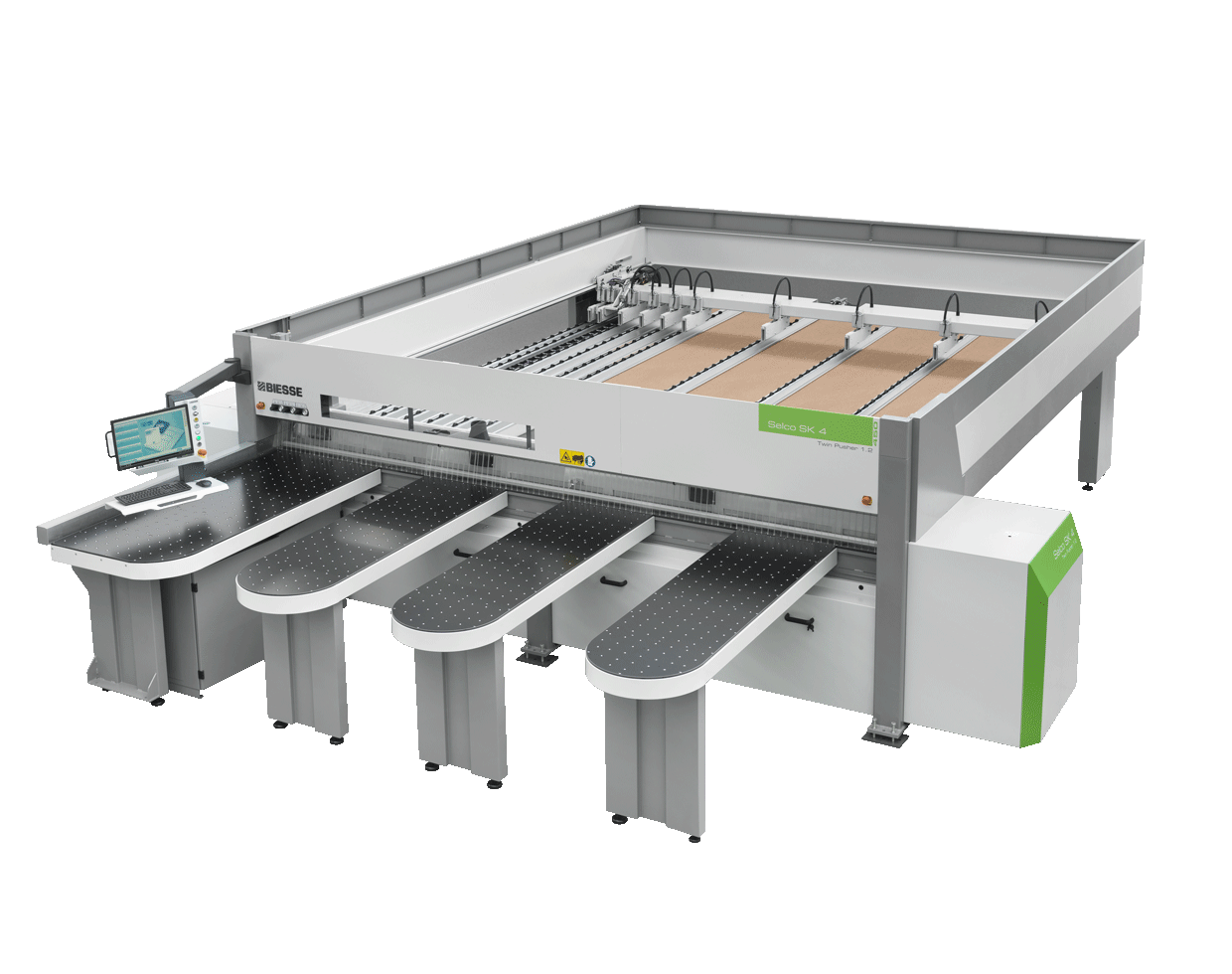

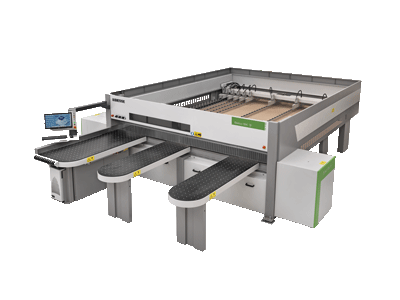

Intuitive cutting-edge technology with reduced footprint

SELCO SK 4 is the range of cutting centres designed to satisfy the needs of small to medium-sized enterprises. It is easy to use, has advanced technical solutions and features great standard equipment.The SELCO SK 4 has become the reference point in its sector.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil