We simplify your manufacturing process to make the potential of any material shine.

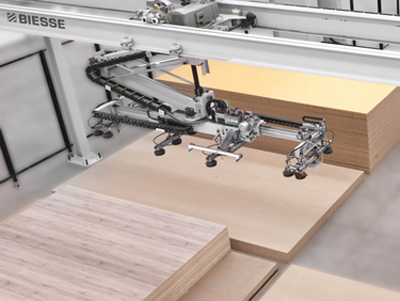

In Southeast Asia, we have successfully established ourselves as a key player in the woodworking and furniture manufacturing industry, providing comprehensive solutions tailored to the needs of the local manufacturers. The region's growing economy has created significant opportunities for our company to expand its operations and market share.

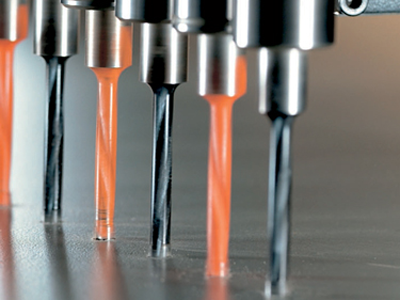

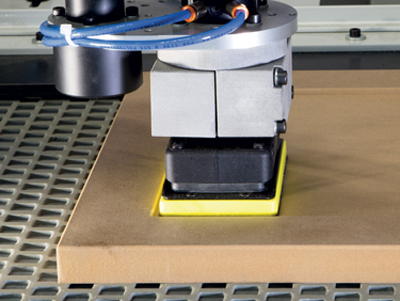

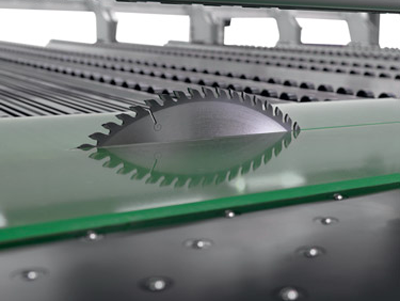

Having extensive experience and expertise in innovating technological solutions, we are leveraging our capabilities to offer solutions beyond wood working. Now manufacturers working with glass, stone and composite materials, including plastic, can benefit from our cutting-edge technologies and high-quality machinery. As a global solution provider, we recognise the immense potential of this market and are committed to providing comprehensive solutions that combine precision, efficiency, and reliability. With a wide-spread portfolio for wood, glass, stone and plastic, we are poised to meet the diverse needs of manufacturers operating in various sectors across Southeast Asia.

With two regional hubs with a fully operational office, Tech Centre and warehouse in Malaysia and Indonesia, alongside our very own experts and specialists providing professional services, we pledge our unwavering commitment to serve our stakeholders in the countries of the Southeast Asian region.