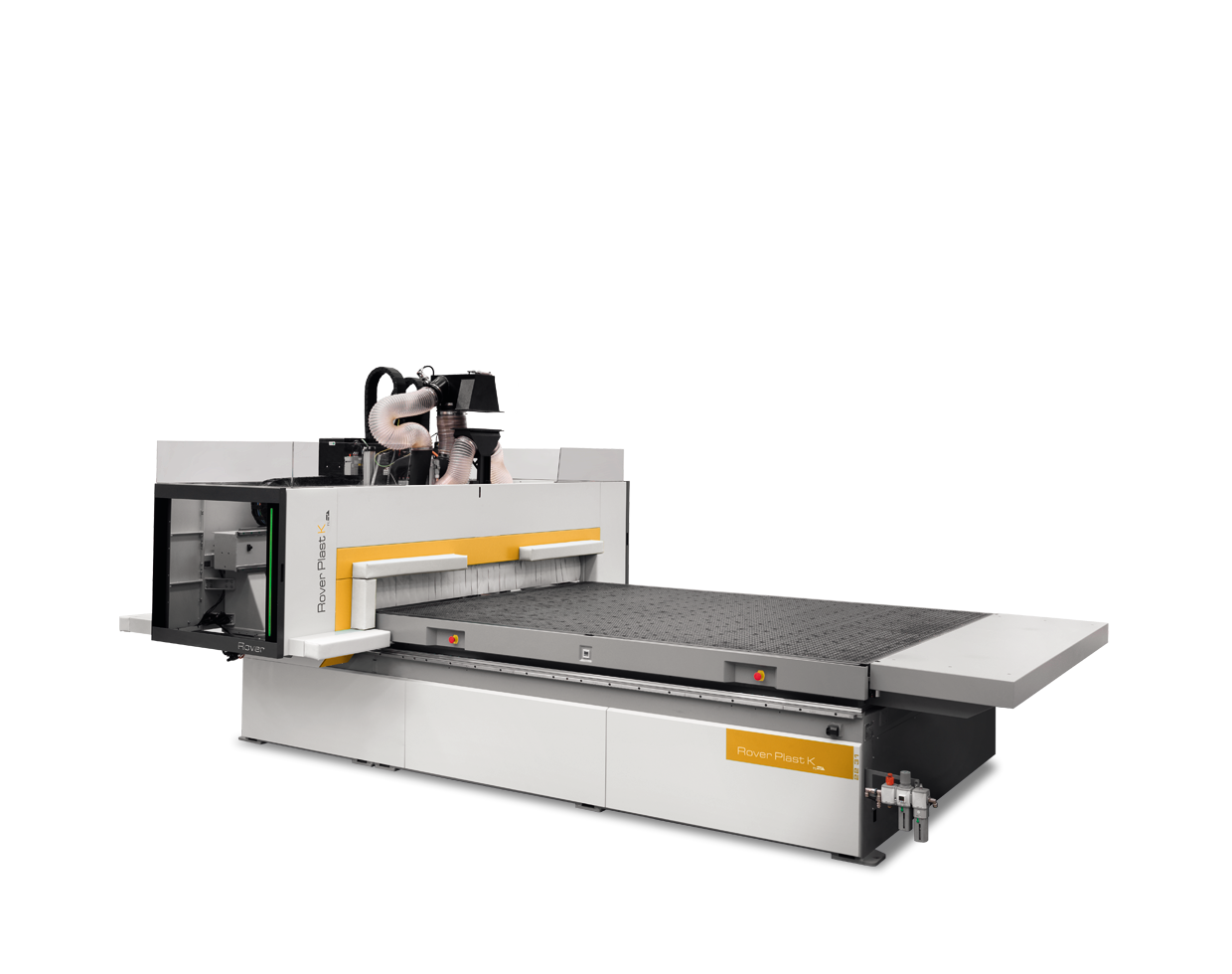

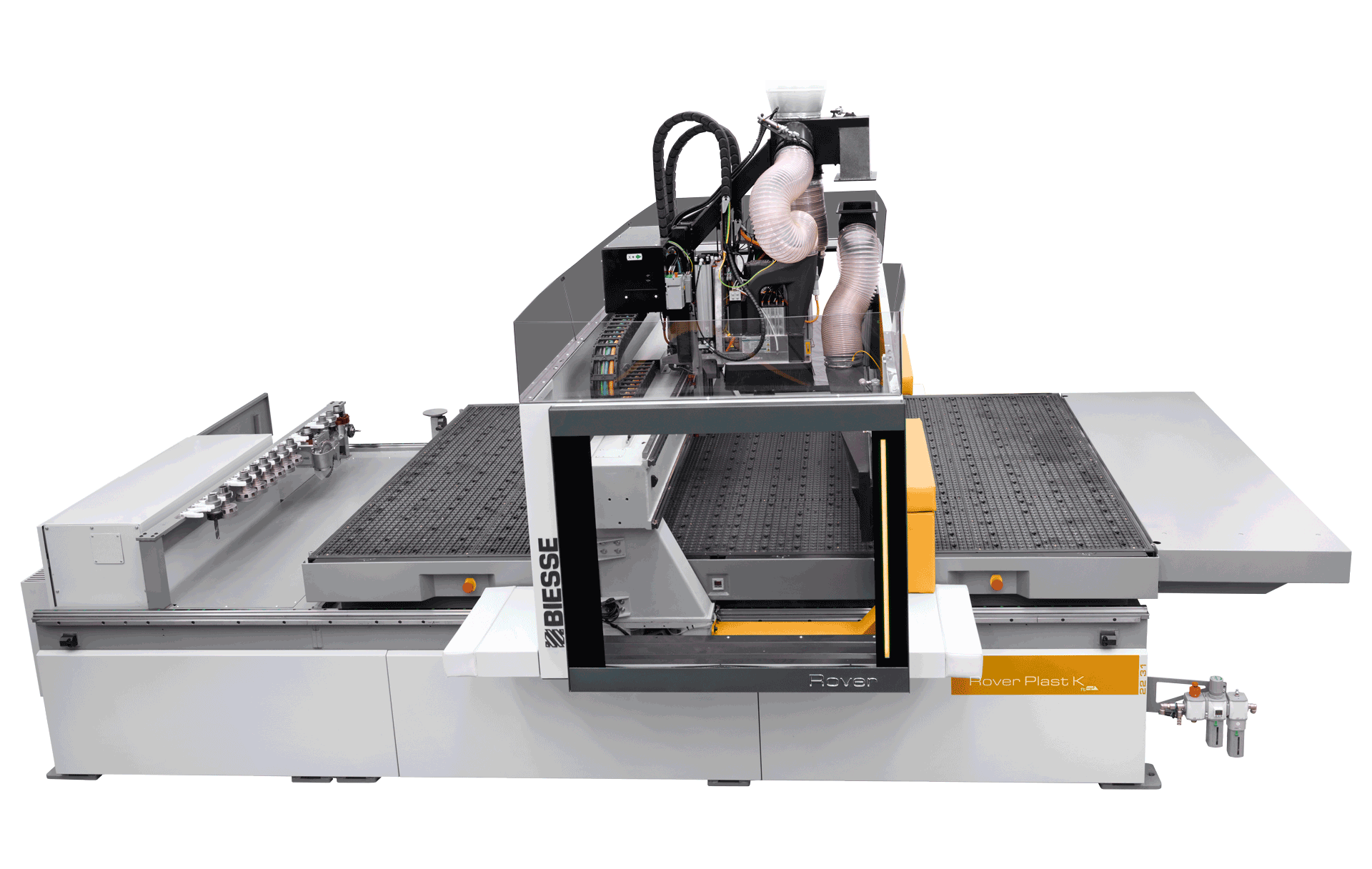

Compact and high-performance solution for milling and cutting of plastic and technological materials

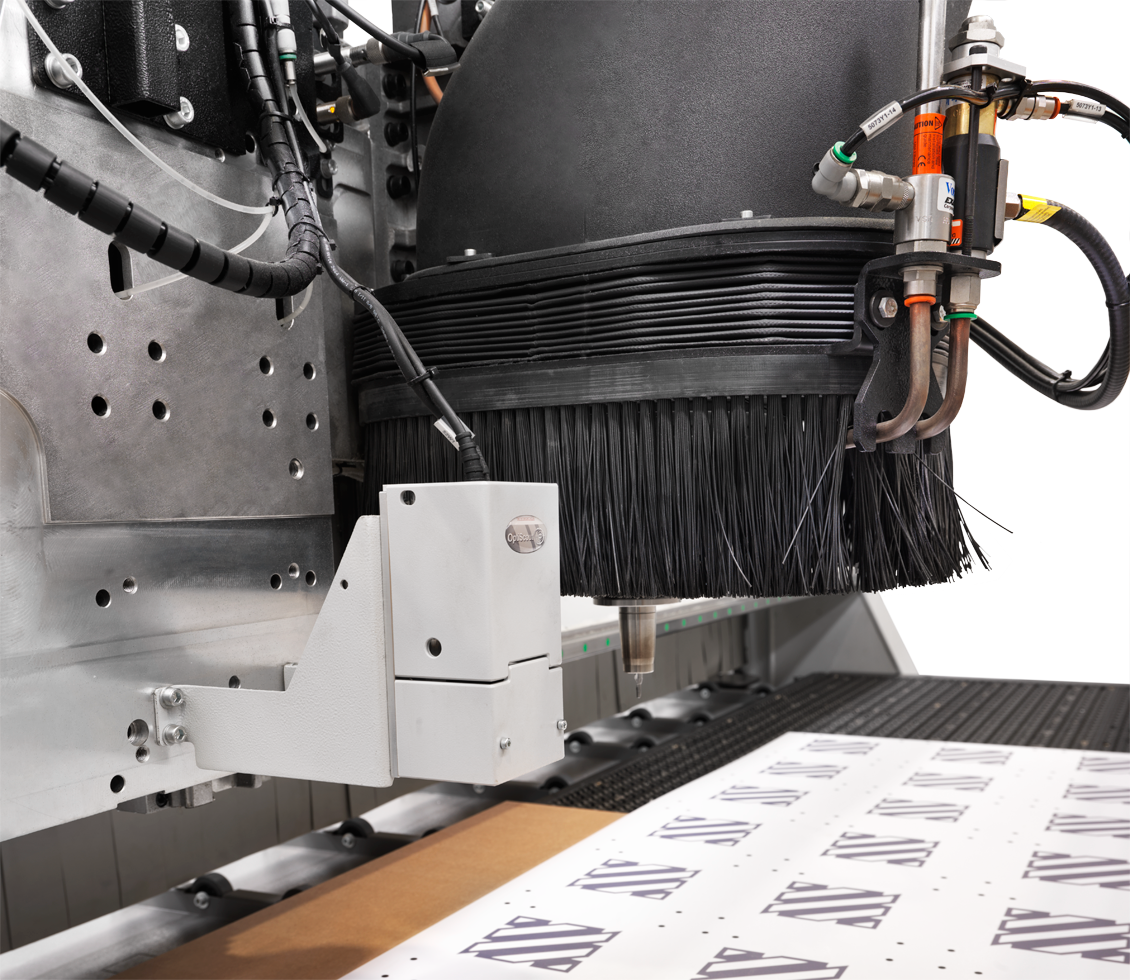

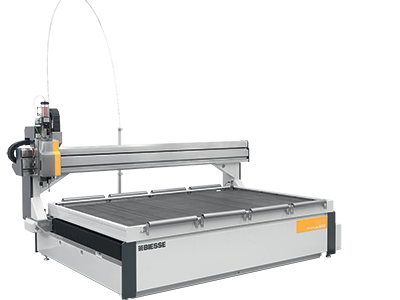

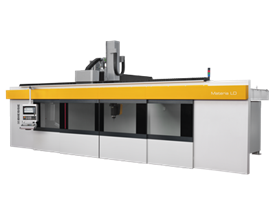

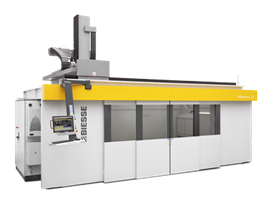

Rover Plast K FT is the new Biesse numerical control machining centre with Gantry structure - the most compact on the market - designed to machine advanced and technical materials used in such sectors as: prototyping, technical articles and visual communication. Rover Plast K FT is the ideal solution for businesses which require flexibility and ease of use within a limited production space.

Мы упрощаем процесс изготовления изделий, чтобы раскрыть потенциал любого материала.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil