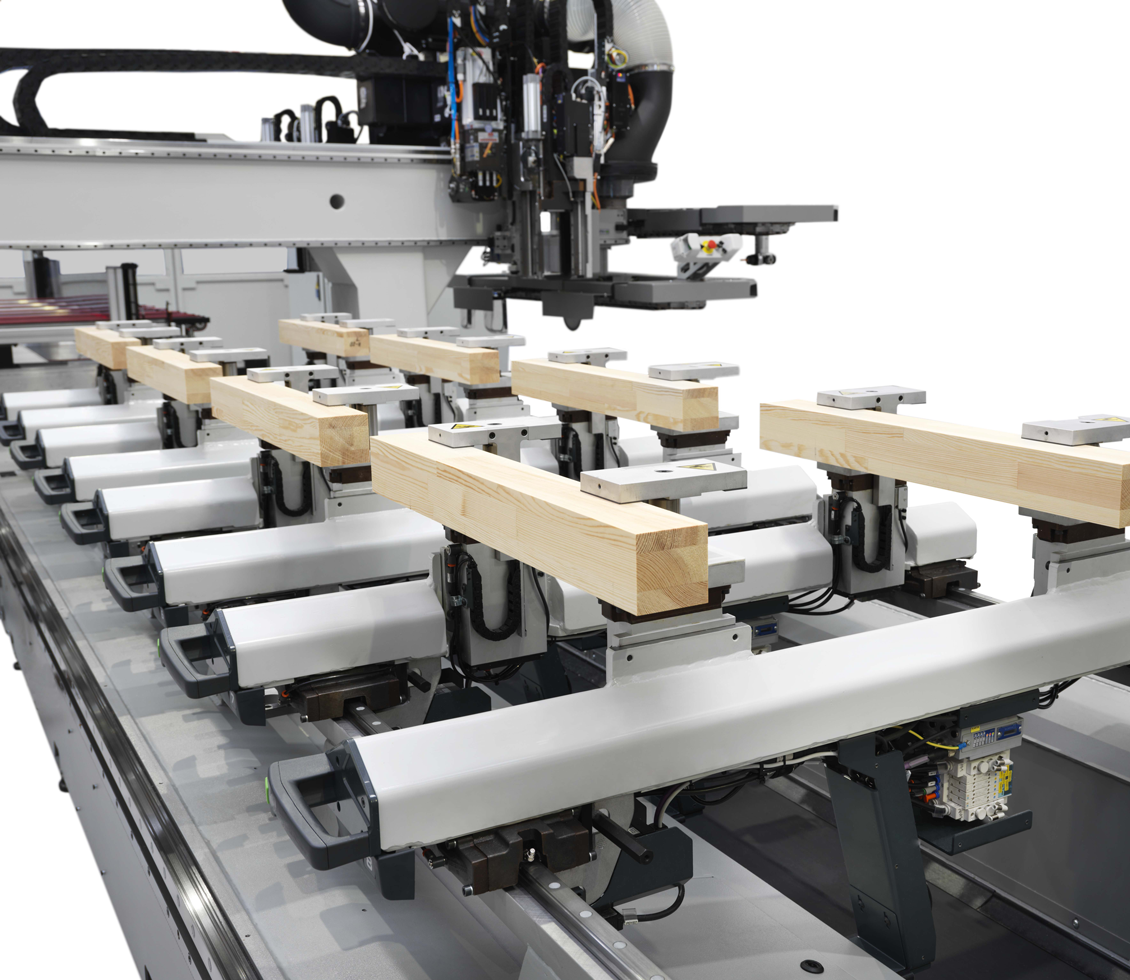

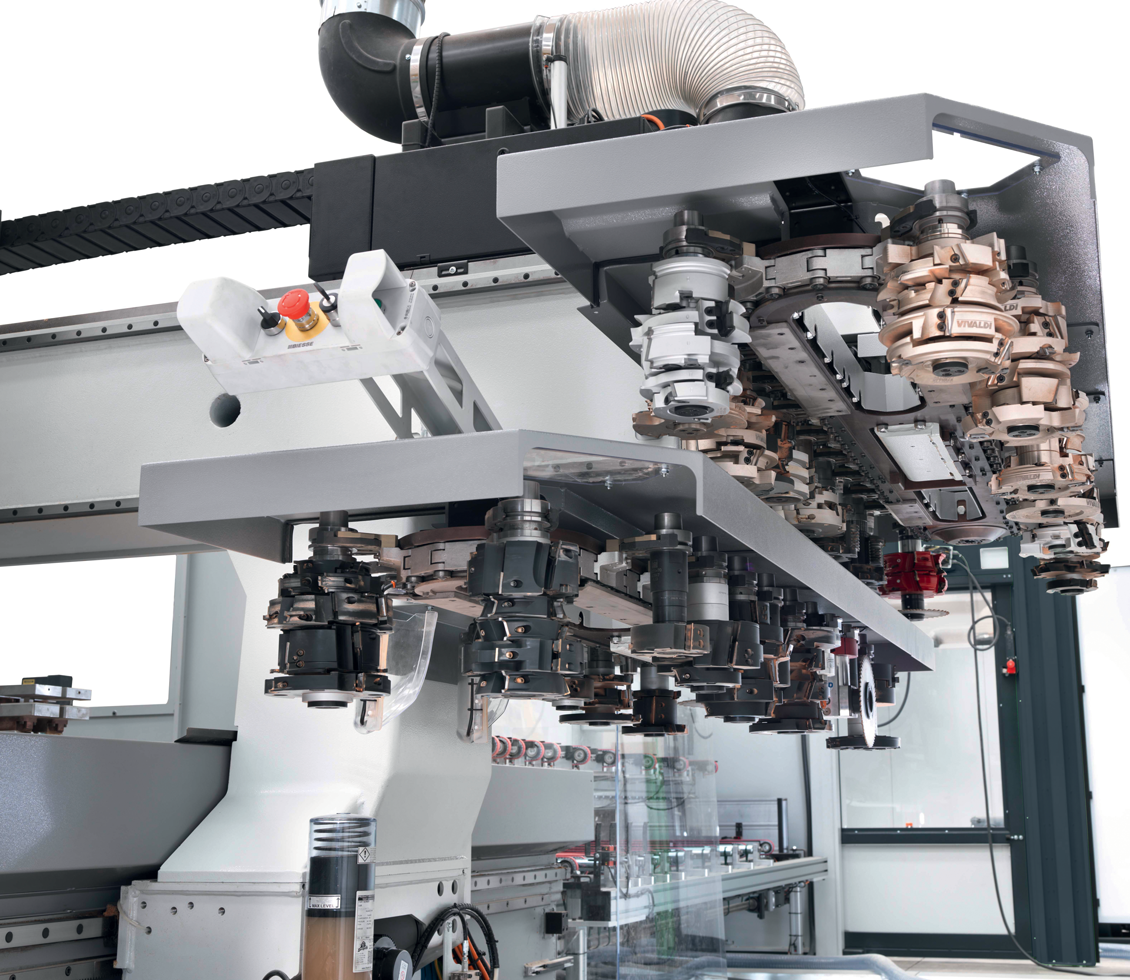

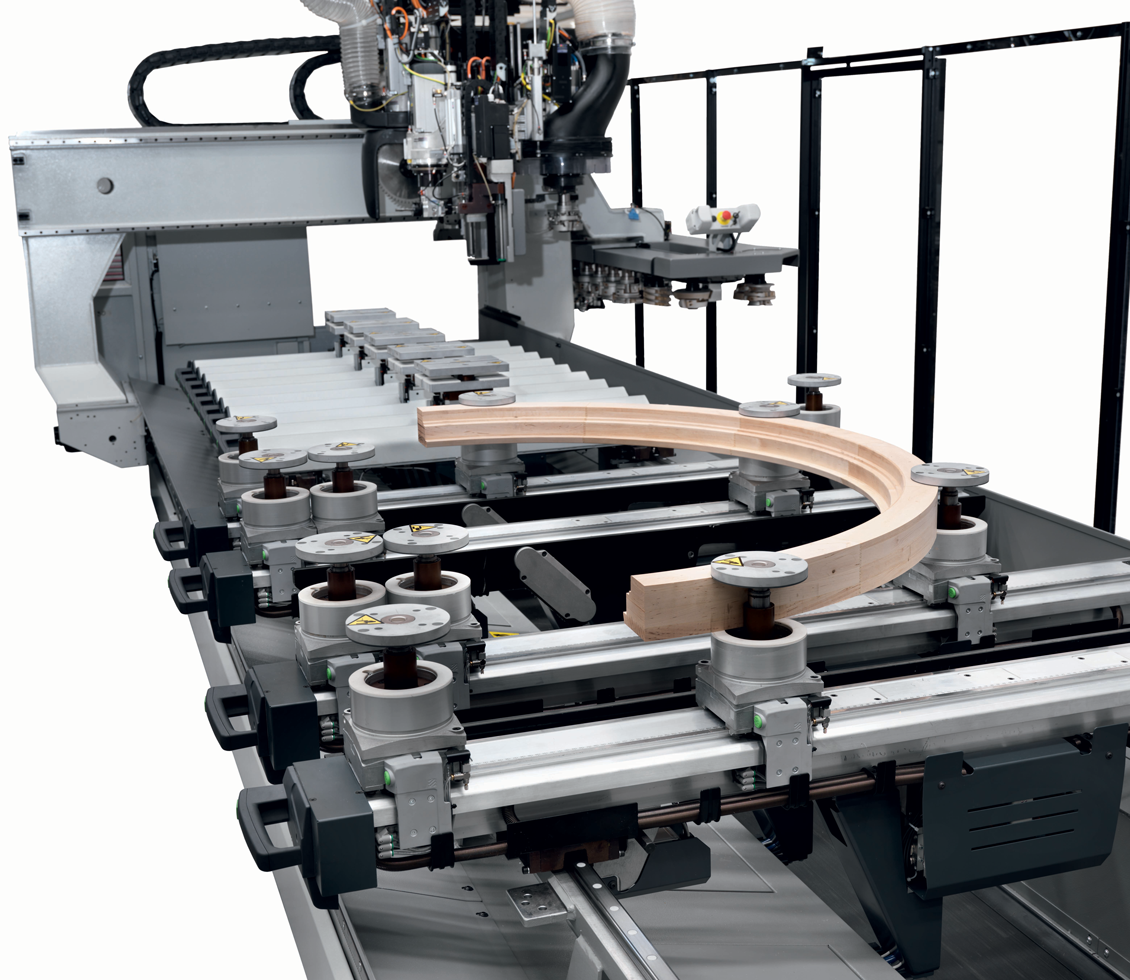

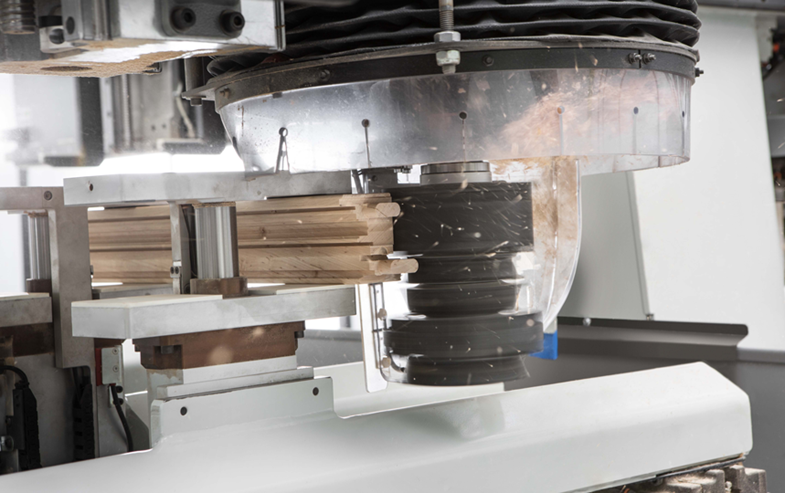

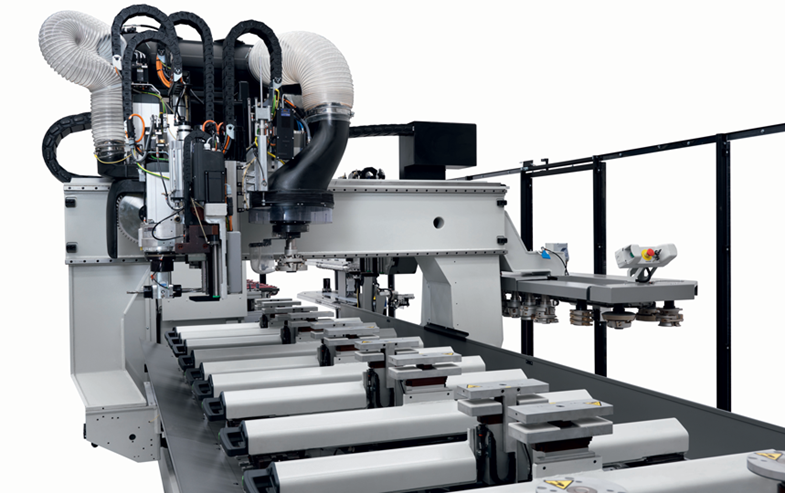

CNC machining center dedicated to the production of components for windows, wooden doors and more.

Winline allows all machining operations, for both standard and special frames, producing any type of window and door frame with any type of joint but always guaranteeing the maximum productivity.

Designed to facilitate the operator’s work: it requires no specific skills, and works with the utmost efficiency.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

.jpg)

.png)

-(1).png)

.png)

.png)

.png)

.png)