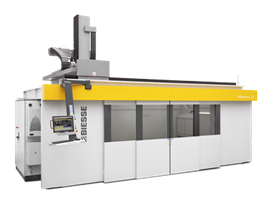

The first solution is an automated line with Automatech Robot which enables the production of components for up to 150 kitchen cabinets per shift with only one operator. Biesse will demonstrate how to store, load, machine, sort and different material types to be processed. These materials are to be automatically processed by routing, drilling, inserting dowels, finished with edgebanding and finally sorting the parts by cabinet. The cell includes a Winstore X2 material management system, auto loading a Rover A nesting cell, robotic offloading and part management through an Elix bore and dowel machine, followed by automatic transfer to a Stream A Smart edgebander. Traditional work cells to accomplish these production quantities, can require over 4 operators while this automated solution reduces this number to a single operator.

The second is a ROS FT + Rover robotically operated system that unloads machine parts from a nesting machine. The ROS FT fits the needs of multiple customers, from the medium-sized craftsman who wants to optimize his workflow and reduce labor costs to the high production shop that wants to reduce waste, get their production fully automated or, to provide their custom department a high efficiency cell. The ROS FT’s dedicated unloading conveyor maximizes the machine’s working efficiency and increases productivity; it can use a vertical trolley to unload delicate parts and can sort panels to optimize the workflow after nesting. It is also a plug'n'play solution, perfectly integrated with the machine.

Enduring Labor Savings

With dramatic labor market shortages and manufacturing labor rates continuing to increase throughout North America, there’s no doubt that these automated solutions pay for themselves quickly with reduced labor costs alone. Additionally, manual labor can be relieved of monotonous jobs, replacing them with processes which have the most inherent value. For example, assembling the box and laminating or painting the door. These advantages are coupled with the assurance of a consistent, reliable production output. These solutions are a direct response to the demand for smart automation in today’s manufacturing environment.The Benefit of Repeatability

Repeatability of cabinet output and part quality benefits from the consistency of both Biesse automated solutions. With streamlined automation, a factory can achieve an even paced production output every single day, because they are not relying on an operator to come into work and then finding a quick solution if they don’t show up.No matter who you are or where you are, everyone is facing labor issues. Biesse’s goal with both of the solutions you’ll see at IWF, is to help customers maximize their labor resources in factory positions which requires the human touch and automating the positions that don’t.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil