Chris Carmeci did what many young and enthusiastic cabinet makers have done; start his own business. The story is all too familiar; do your apprenticeship, start making kitchens in the garage for friends and family, move into a bigger premises and you are off and running. Unfortunately, the story often stalls after only a few years as the young man finds it harder than he realised and with little business sense, eventually goes under. But Chris hasn’t followed the script and after eleven years, thanks to some help and sound advice from family, hard work and key machines from Biesse, Precision Cabinetmaking is stronger than ever.

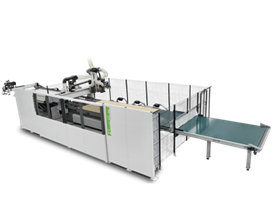

Chris and his wife Rebecca represent the essence of a small family business in Australia. The sector employs over five million people, or put another way, a figure approaching half of all workers in the private sector. Small business is a crucial component of Australia’s success story, but success requires a commitment to your customers; a quality product and the ability to make a decent living and provide growth for the company. To achieve these crucial goals Chris and Rebecca recently installed a Rover S CNC nesting machine with automated panel handling.

A few years after Chris had completed his apprenticeship and with some experience under his belt working for several diverse kitchen and joinery companies, he decided to go it alone. A small panel saw, a hot-air edge bander and a machine to drill and insert hardware was all he needed to start out. Over a three-year period, Chris worked long hours to develop a client base, get some sound business advice and completed an advanced TAFE course. Chris learned from his mistakes to establish himself as a trusted manufacturer, and plan for the next step.

And so, at only 26 years of age Chris moved from the garage to a modest workshop in Dural in Sydney’s North West. Within a year of the move he had employed another person, and it was time to look at some new technology. Over the next five years the panel saw, and edge bander were both replaced twice as the company grew. A move to nearby Rouse Hill was followed by his final move to Riverstone two years ago. It was now time for Chris to think about a CNC machining centre to speed up production and stabilise his quality. Chris was fortunate to come across a used Biesse Klever CNC nesting machine he knew was in really good condition, but he did not anticipate what was to follow.

What followed was totally unexpected. Chris admits that at first, he didn’t know much about the 2.4 by 1.2 metre Biesse Klever other than it suited his production and “Everything stacked up right for us.” He’d bought it privately and expected to be on his own, but Biesse was there to help. He said, “I didn’t even know how to turn it on but the guy’s at Biesse came out to get me going and followed that up with a lot of help over the phone. You don’t see that too often, a company helping you when you didn’t even buy the machine from them. They went above and beyond even my wildest expectations. They would even stop by from time to time to see how I was getting along. The trust we have in Biesse started from day one!”

Rebecca was now looking after the books and helping out a few days a week in the workshop. Their work is now high-end residential kitchens and bathrooms, but they also produce wardrobes; entertainment units and other occasional furniture. Chris says, “We never wanted to grow too quickly, we prefer steady growth. We comfortably do one kitchen a week and we often find ourselves putting out jobs valued at several hundred thousand dollars. We concentrate on quality. Most of our kitchens are open plan and focused on design and quality. We think our ability to produce what our customers want while offering the personal service bigger kitchen manufacturers may not be able to, is a point of difference. 70% of our work is renovations and 30% are new builds.”

Chris recalls the Klever only needing a few minor parts over the last two years. He said, “Biesse know their machines inside-out; the service has been great, they’re more than obliging and have always got me back into production quickly.” Their relationship with the leading technology partner is excellent and so, only a few months ago Chris and Rebecca decided to invest in a new, larger Biesse Rover S CNC nesting machine with automated panel handling that would reduce their machine labour and speed up production. Chris would also have more tool change positions to reduce setup time for their routered door profiles, and be able to produce taller, three-metre cabinets.

Chris and Rebecca report the purchase experience was seamless. He said, “Our experience with Biesse has been amazing. Everyone has been up front and honest with us, they’re easy to talk to and not pushy at all. They gave me the time I needed to look at which machine would suit my production, to find out as much as I wanted about the machine. No question was too hard or too stupid for them to answer. And when it came time to instal the machine, that went without a hitch. Nothing was an issue for them, even the crane driver. The techs knew exactly what they were doing. They were able to identify a small part that was missing and had it delivered in time to have the machine commissioned on the day they said it would.”

“A CNC machine is a fair investment for a small business, but we had confidence in Biesse to know what they were doing and to help us whenever we need it. We didn’t hesitate to go with Biesse product. I use the Rover S myself and find that I’ve a lot more time to do other things while the machine is handling the larger sheets, processing the parts. We use a third-party kitchen design program and I hardly ever have to get on the machine to program anything myself, except for other products the new machine has enabled us to do. It has opened up a new opportunities for us,” said Chris.

Chris and Rebecca’s business philosophy is to give their customers personalised service at a good price. Quality is a key consideration; Chris says, “Our product needs to last. If our customers don’t get twenty years from their cabinets, we haven’t done a good enough job for them. We use quality board and hardware and our Biesse Rover S always gives us a consistent, high-quality result.” Quality of life is important for any small business owners and their Biesse CNC machine has given them peace of mind, extra time, and the ability to expand if they want. Chris says, “Our reputation depends on our Biesse machine.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil