We simplify your manufacturing process to make the potential of any material shine.

Quality is the level of excellence evident in a finished product while ‘craftsmanship’ is the quality of design and work; the skill with which something was made or done. A new startup in New Zealand’s South Island aims to push the boundaries of interior design, quality and craftsmanship.

Better than perfect with Biesse

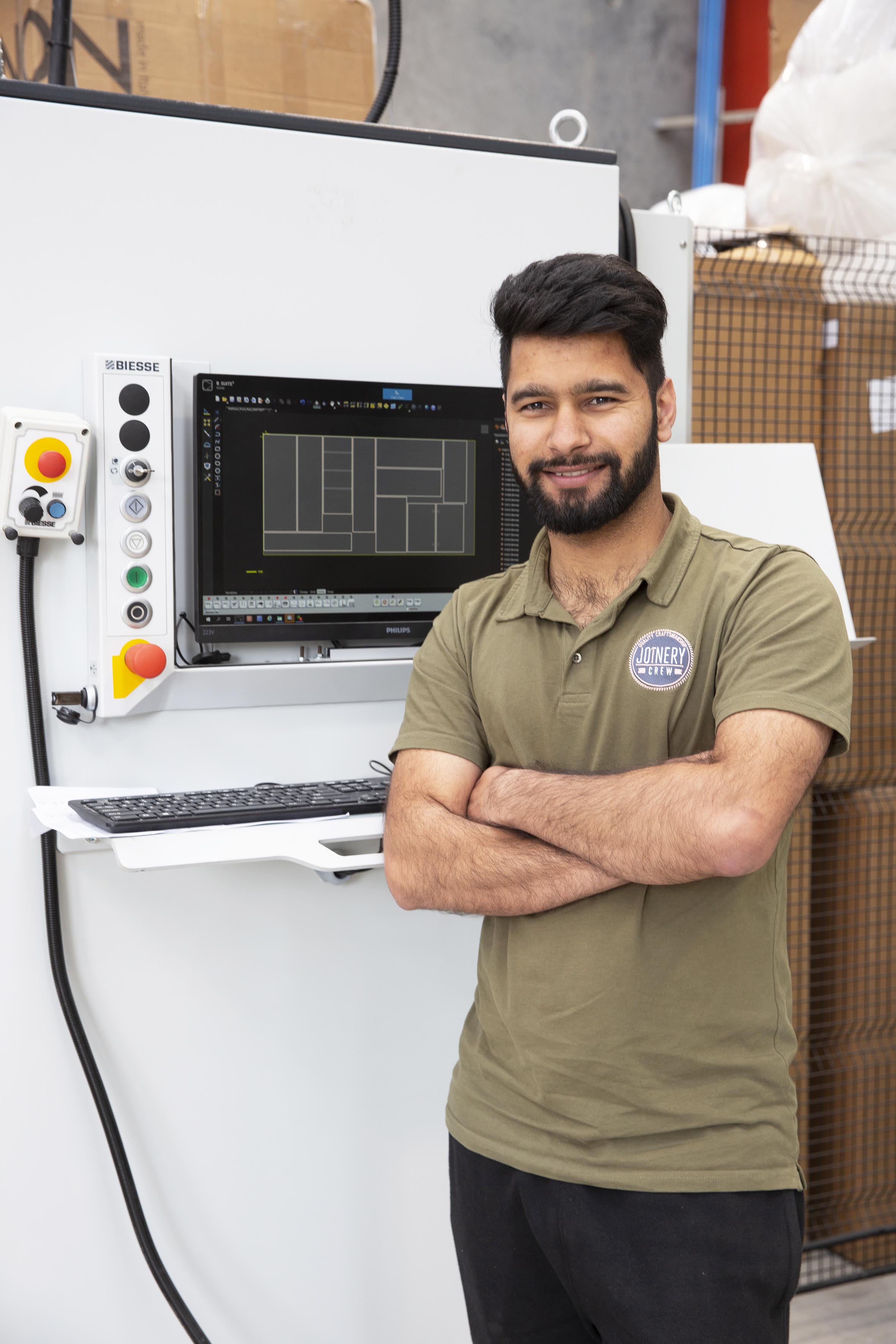

Joinery Crew is a brand new startup company based in Wanaka, New Zealand. Manufacturing started late last year in in a brand-new custom built factory. However, the Joinery Crew team brings over 25 years of experience and know-how to the industry. Specialising in high-end architectural joinery and cabinetry, Joinery Crew manufactures and installs beautiful and unique bespoke joinery. Directors Melanie and Bradley Craig, Sheetu Bishnoi and Anil Kumar are committed to delivering to their customers a level of unparalleled quality and craftmanship.

Anil and his partner Sheetu emigrated to New Zealand in 2012. An engineer by trade, Anil took up a position in a local joinery business where after a few years, he led the production. Moving to multi-award winning Bays Joinery in Nelson as project manager, Anil engaged with their high level of craftsmanship, and became involved with one of Bays Joinery’s clients, well-established interior design architect, Melanie Craig. Anil was looking to move forward, possibly with a company of his own and Melanie saw advantages in becoming involved with a producer aligned to her philosophy of unique detail, form based designs and high levels of individualism.

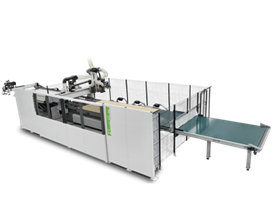

And so, Joinery Crew was established in September 2022 to focus on quality and their client’s specific and individual needs. In order to meet these demands, Melanie, Bradley and Anil went to Biesse Group for flexible equipment backed by service Anil had experienced with other companies. Their two key machines are an Akron 1330 edge bander with airforce (Zero Joint) technology, and a Rover S FT (flat table) nesting machine. Biesse provided start up training and followed this up with further training as needed, due to the company being a new startup with special needs that Biesse Group were all too eager to satisfy.

The Crew

Anil is a director and facility manager and brings with him years of operations experience with a sound hands-on understanding of detailed cabinetry production. Anil promotes the wellbeing of the crew as a key factor in the company's future success. Melanie is a director and develops and oversees all growth strategies for the company. She is solely responsible for the company's inception, developing the ethos and base principles of how the facility functions. Bradley is one of the four directors and is responsible for scheduling, accounting and co-ordinating deliveries and installs.

Matt is a master craftsman from Switzerland. He deals in complex designs requiring innovative problem solving ability and technical know-how. Matt is backed up by Manish who has the programming background to ensure Joinery Crew’s Biesse Group investments operate as intended. Cameron is inspired by family involvement in the design and fit-out industry and brings his extensive construction and window joinery experience. Sheetu helps in the accounting side of Joinery Crew.

Crew Aims

Joinery Crew aims to deliver an unparalleled level of craftsmanship to their clients. Specialising in high-end whole house designer fitouts, Joinery Crew works with Melanie Craig Design to ensure their clients’ specific requirements are met and there is a very smooth transition from design to build. To facilitate the efficient manufacture and movement of components through production, Joinery Crew’s Biesse machines will be an integral factor in setting high quality standards while ensuring speedy and effective delivery of components to assembly. The quality of the final product is what makes Joinery Crew stand out.

Anil said of Biesse’s machines, “I’ve seen Biesse machines in the other companies I worked for and even after twelve years they are still ‘going like a rocket’. We rely on the skills of our crew to present the final product to our customers, but we also rely on our Biesse machines. Our Biesse machines are critical to our intended objectives.” As for Biesse’s service, Anil said, “We haven’t had a service yet but because we are a new company we needed Biesse to come to our aid from time to time when we started using the machines full-time, and I can tell you that Biesse were always there for us.”

Joinery Crew’s factory is built with the future in mind. Their choice of building materials is environmentally friendly, and they rely as far as possible on solar energy. Their choice of Biesse Group machinery was also made with consideration to their future. A strong, secure machinery partnership with a company that will always be at their side will be crucial to the ongoing success of this startup. To provide the craftsmanship the company offers to their clients, no small detail can be left to chance. This includes the panel edges where 90% of our production is with laser edgetapes applied with the airforce unit onboard the Akron 1330 to give us a “zero glue line. As Melanie said, “It has to be better than perfect.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil