Biesse Ibérica attended Equiplast 2017, the international trade fair for plastic and rubber held in Barcelona in October 2 to 6.

Biesse presented flexible and innovative solutions to help the plastic sector professionals have a higher precision, reliability and safety in their work. Also they received advice on the best ways to optimize their production processes and achieve a better profitability.

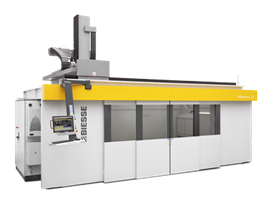

The visitors had the chance to experience live the Materia CL 3015, our versatile, compact, 5-axis processing centre designed to meet a wide variety of high-speed machining needs in relation to the milling of advanced and compound materials and special or stratified resins for mould models, the machining of thermoformed elements, unusually shaped three-dimensional elements, and components for the aeronautical sector, boats and the car industry. Materia CL can be equipped with an efficient system for vacuuming up machining dust, and a full upper casing that encloses the machine completely. The optimum safety level is guaranteed by the manual or automatic doors opened from the front and fitted with large inspection windows.

Once again, Biesse thinks forward and shows its commitment to innovation, serving new sectors like the machining of advanced materials, and answering the market’s needs.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil