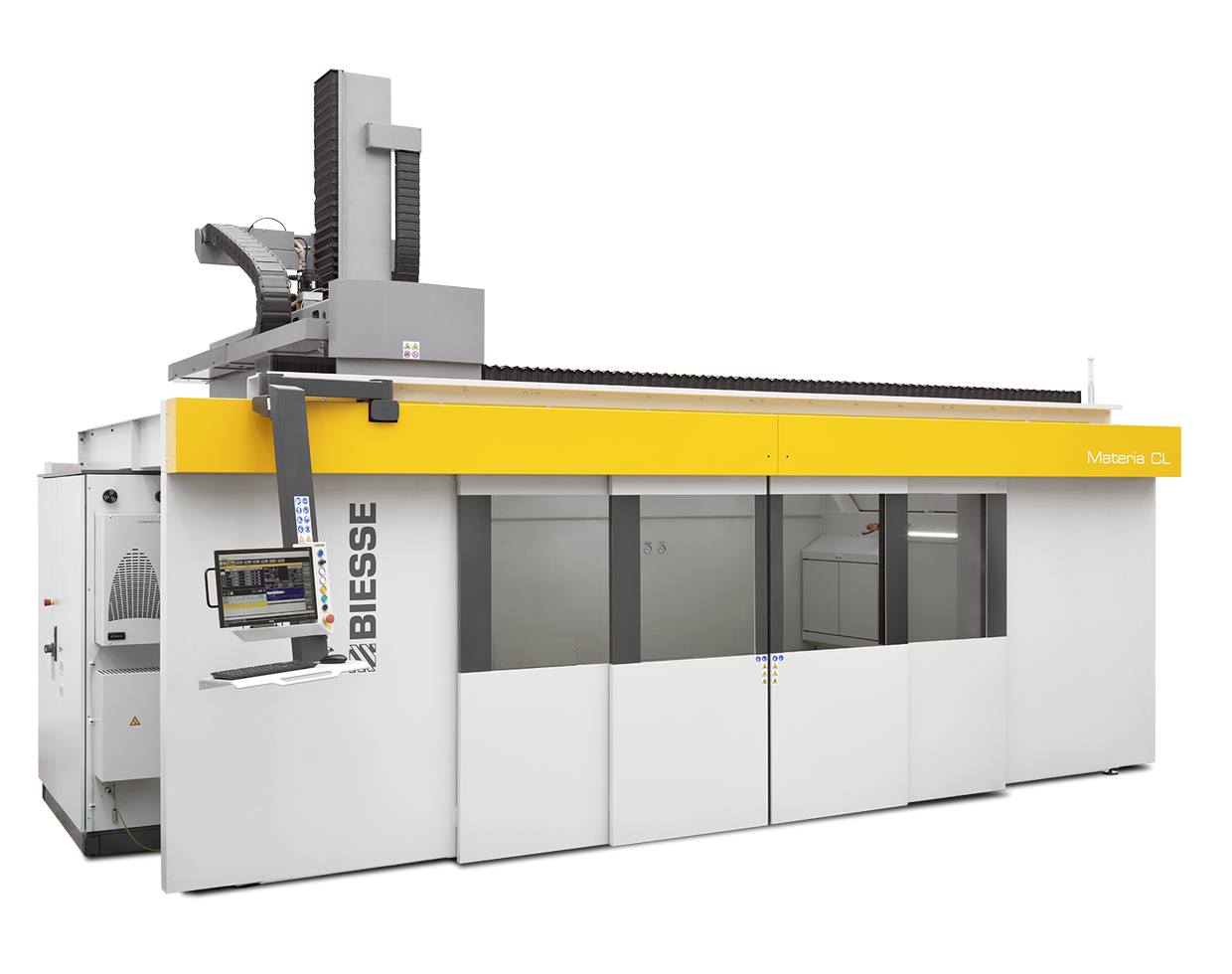

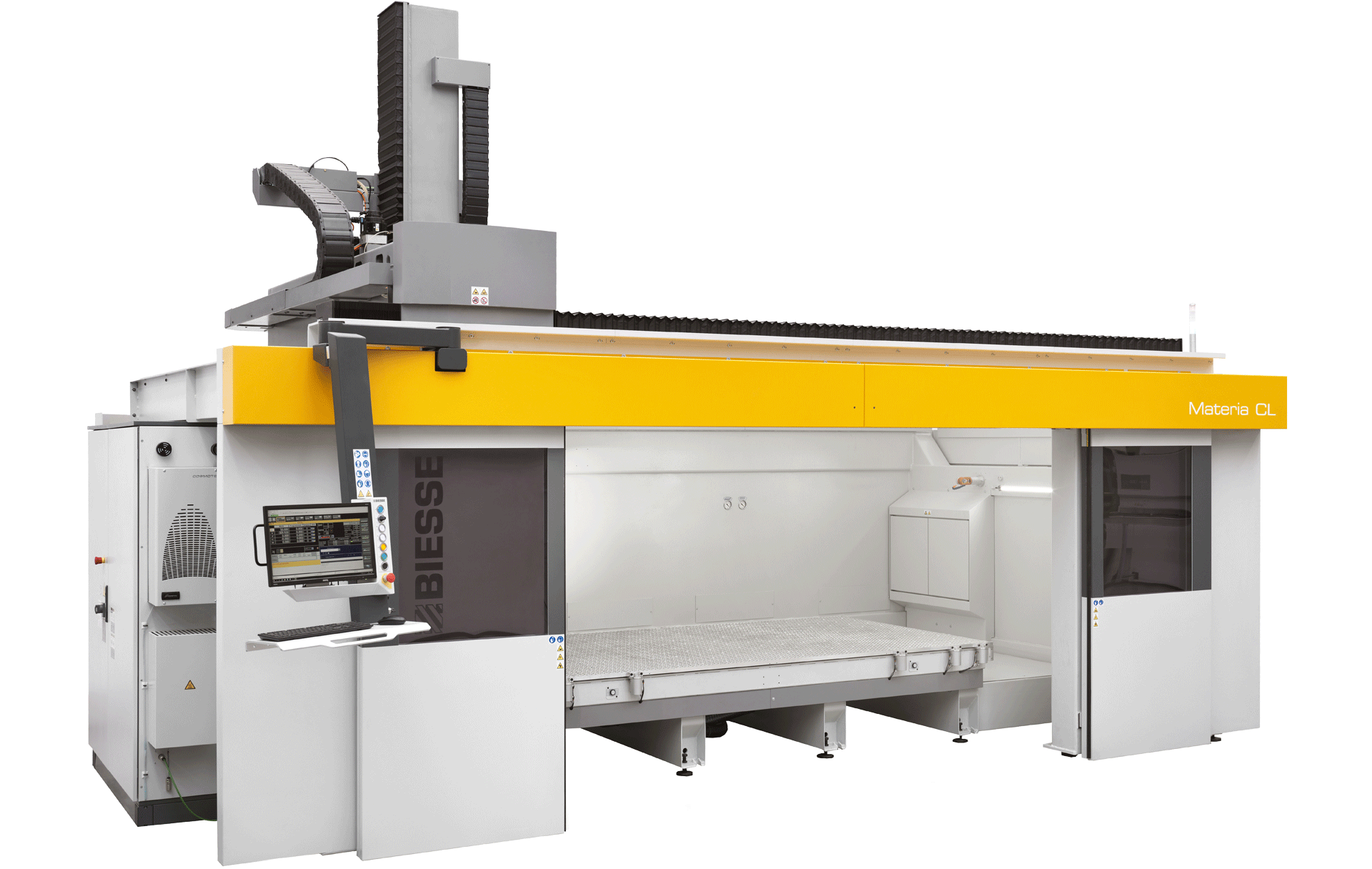

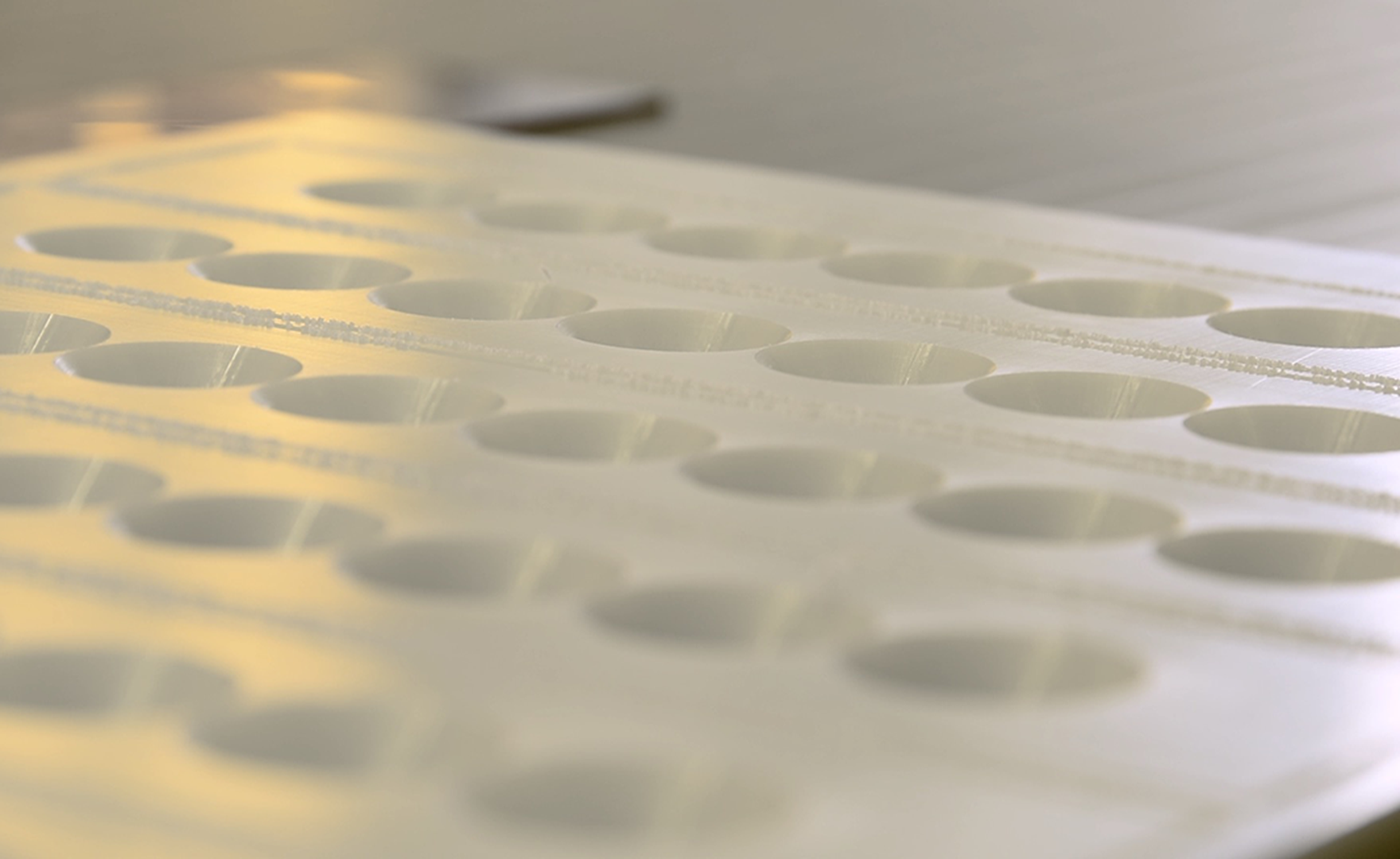

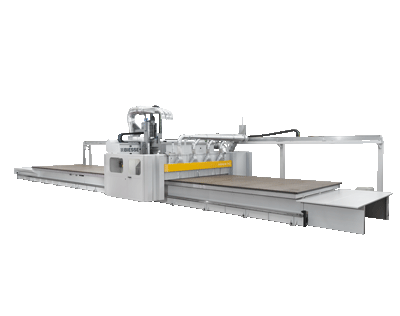

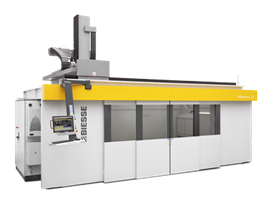

Materia CL is a range of versatile, compact, 5-axis processing centres designed to meet a wide variety of high-speed machining needs in relation to the milling of advanced and compound materials and special or stratified resins for mould models, the machining of thermoformed elements, unusually shaped three-dimensional elements, and components for the aeronautical sector, boats and the car industry.

We simplify your manufacturing process to make the potential of any material shine.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil