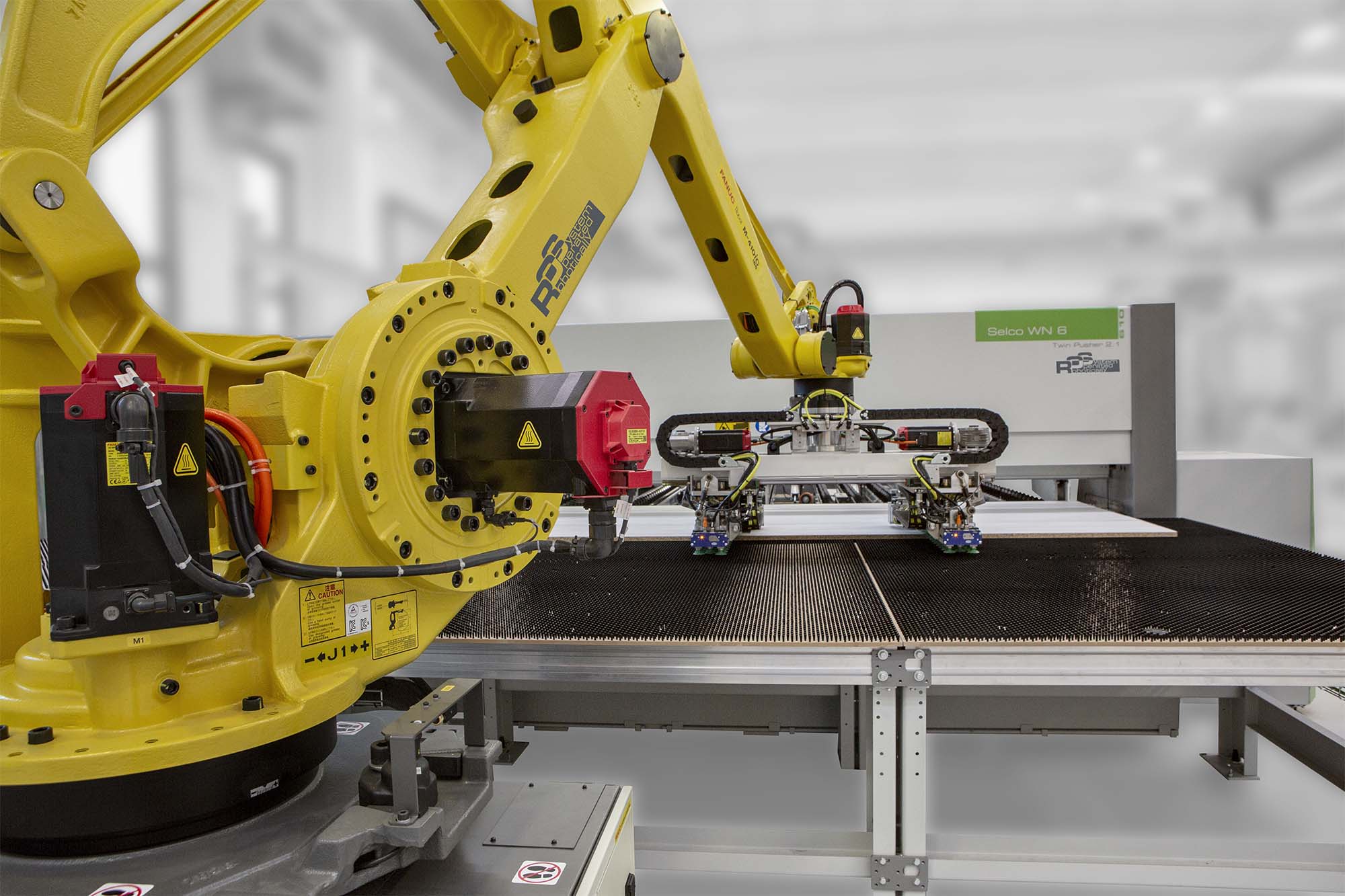

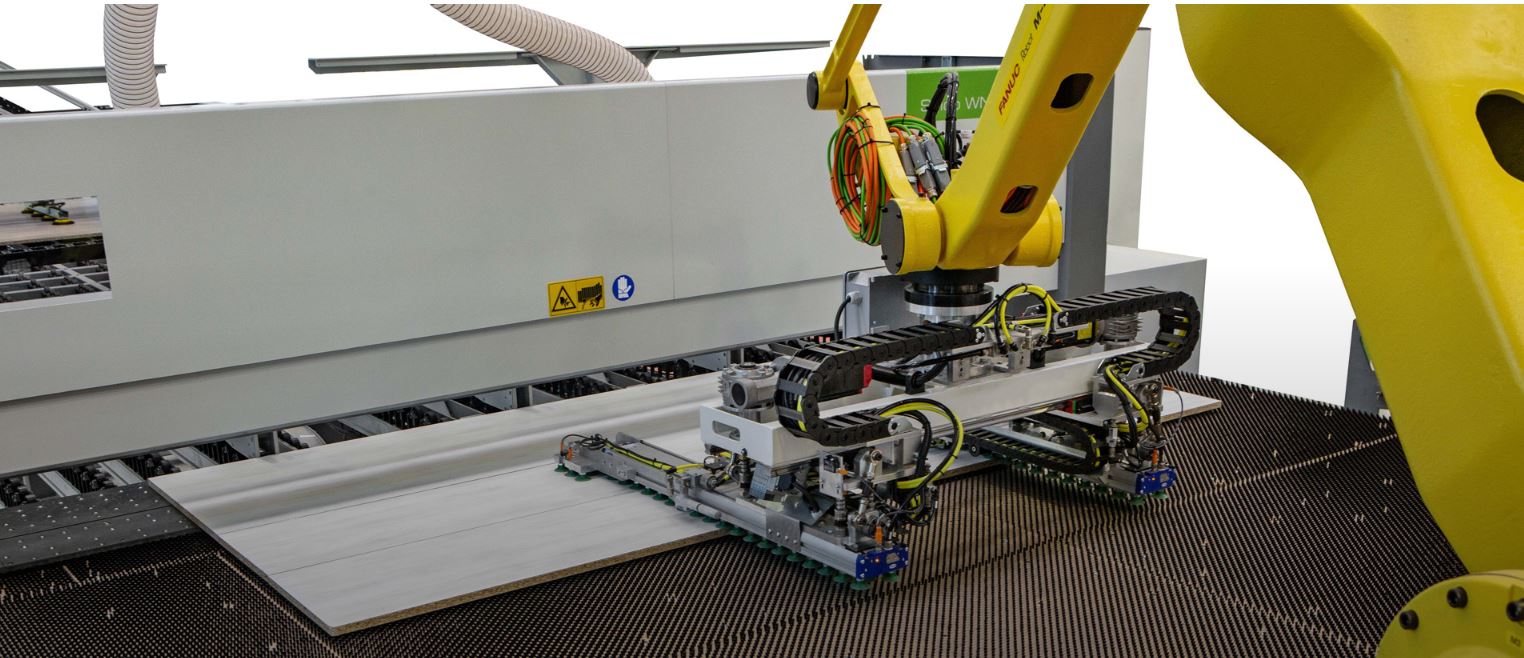

Automation, Technology and the Benefits of Biesse's WN 610 ROS Machine.

Over the last couple of decades, the drive towards automation and robot technology has been relentless. Tireless, reliable, and capable of the same performance at the end of a shift as they deliver at the beginning, robots ranging from automated warehouse systems, to feeding and stacking options are really taking the spotlight, and even small companies can benefit from their versatility.Back in May 2019, Biesse demonstrated its digital factory solution under the Automaction slogan. Its an industrial production solution that coordinates people and robots, and demonstrates the infinite capacity offered by machines.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil