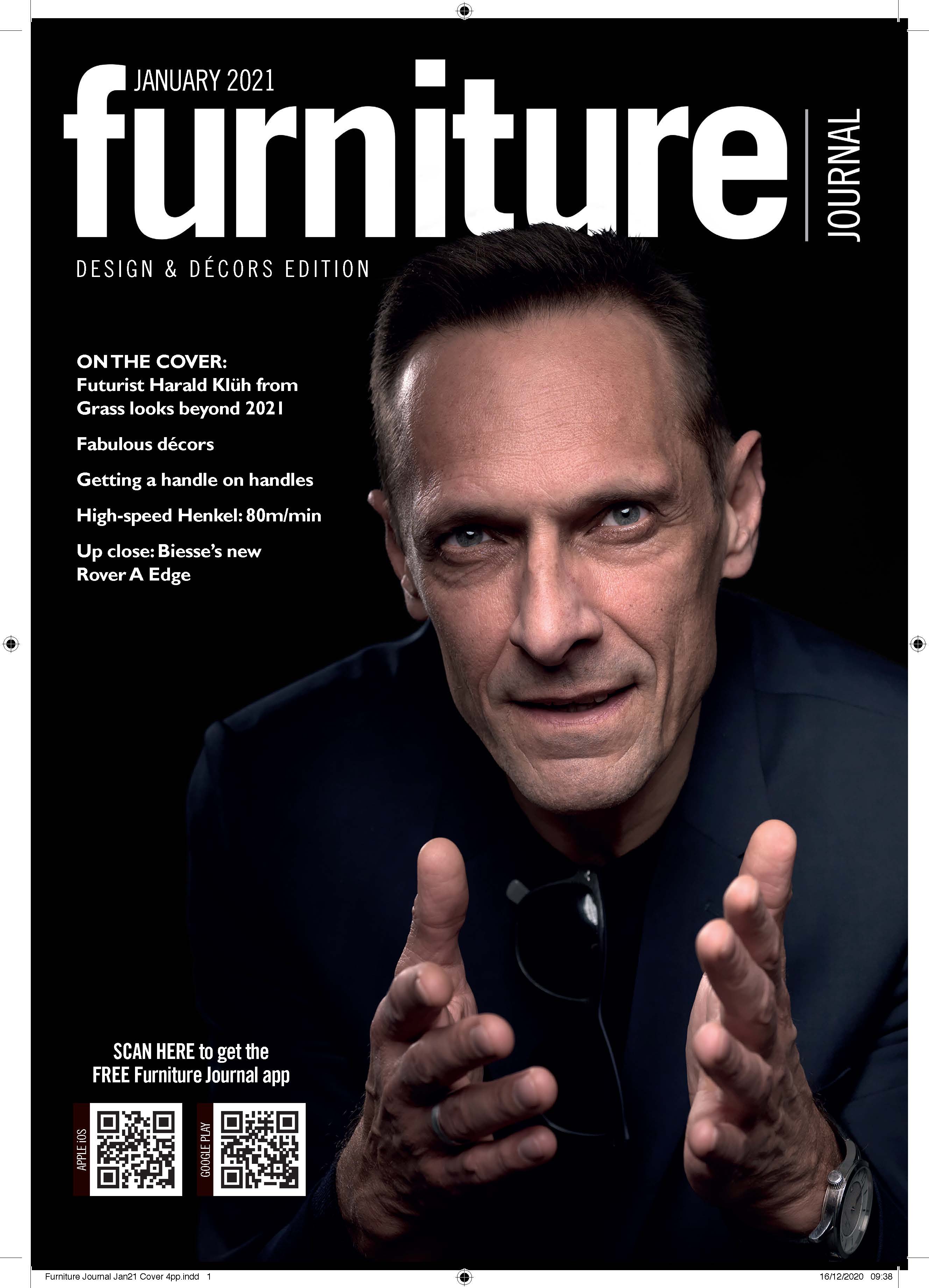

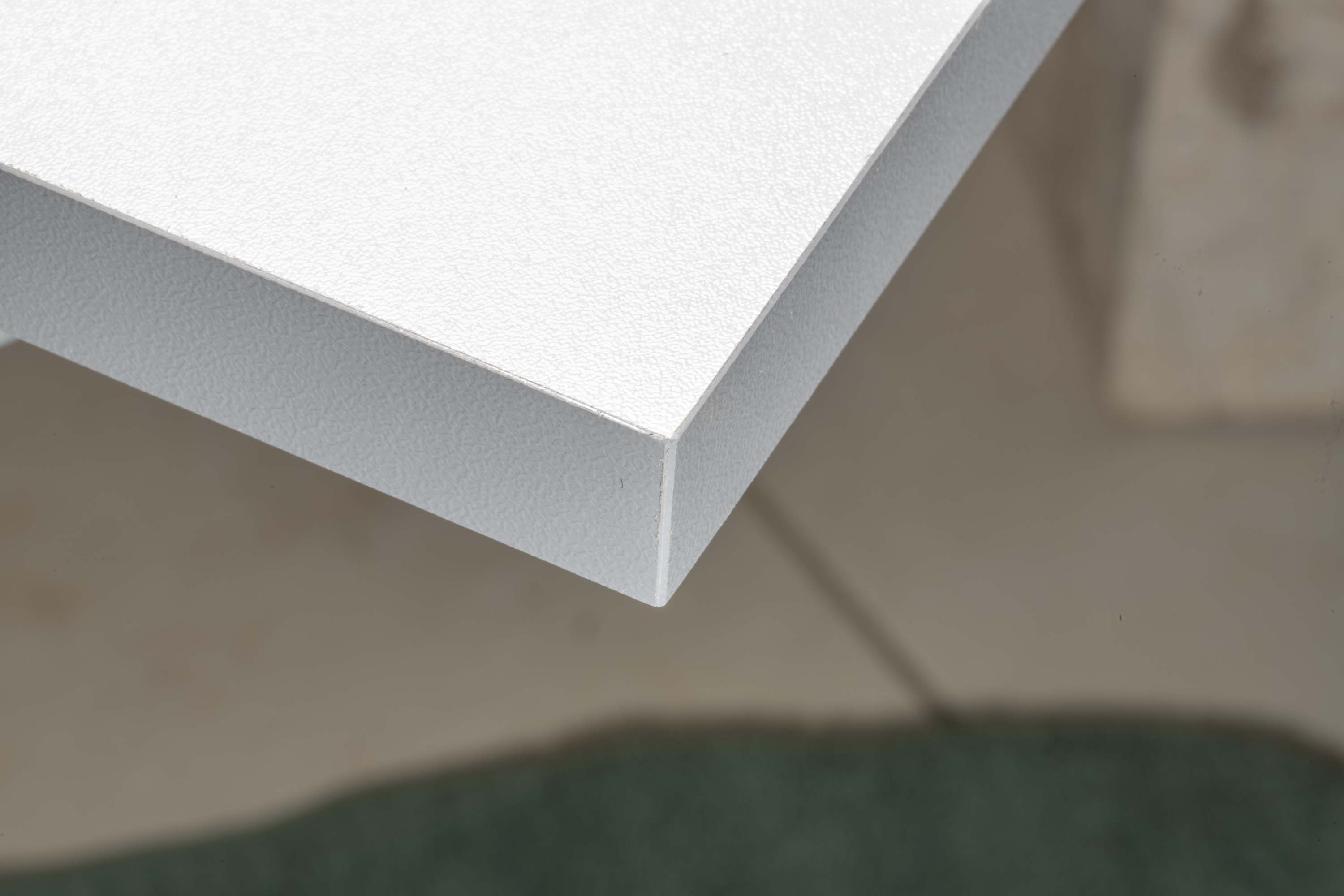

If you want matching quality on your curves and straight edges, that’s what Biesse’s 'Rover A Edge' is designed to give you.

Are you in the market for a machining centre that will perform all your routing, drilling, grooving, horizontal boring and edgebanding in one pass? Do you need a machine that will give you the same edge quality on curves that you’re currently getting out of your straight-line edgebander? If the answer is yes to both questions, then you really need to take a closer look at the brand new Biesse Rover A Edge.The really clever bit is the Rover A Edge will apply edges using EVA, PUR, or even laser edgebands using Biesse’s unique Rayforce infra-red system. As you might expect, there are some very clever features on the Rover A Edge that will save you time and help you maintain the same quality of edge consistently.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil