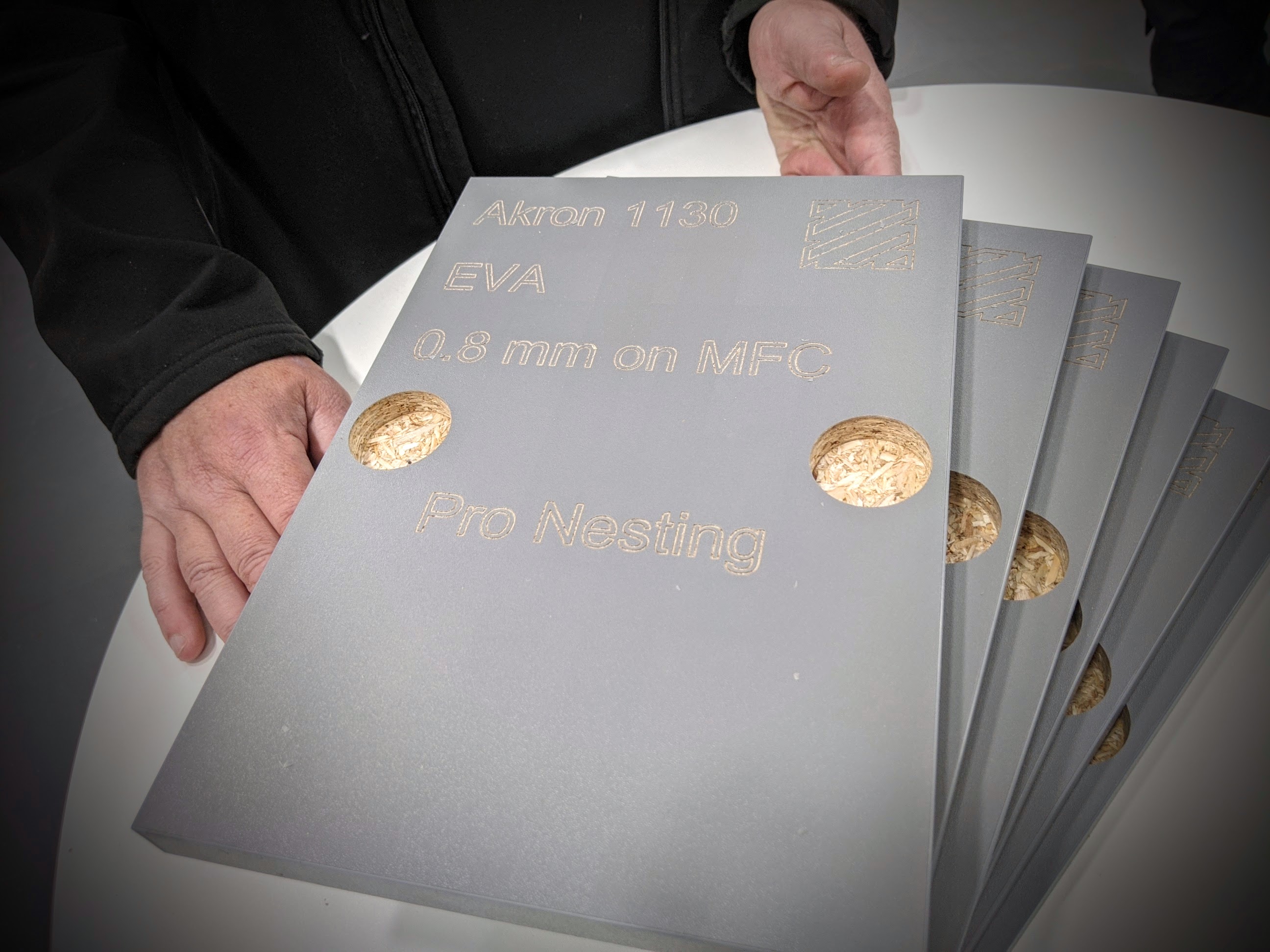

Drilling panels before you edgeband? Guarantee quality and consistency with Biesse’s Pro-Nesting solution. Biesse’s Pro Nesting feature is now available as an option on every machine in its range, giving entry level users access to this tried and tested solution for edge-banding pre-drilled panels without any issues or inconsistencies Available on: AKRON 1100 series upwards

When might pro nesting be needed?

Pro nesting is beneficial when panels have been pre-drilled with holes for hinges, dowels and other fixings, and the holes are close to the edge. Panels that are produced using the cut-edge-drill process, whereby they are cut to size and edge-banded before being drilled, will not require pro nesting. Where pro nesting adds value is when panels are produced via a CNC nesting process and drilled before edge-banding.

What is the problem with pre-drilled panels?

Usually when edge-banding a panel that hasn’t been pre-drilled, top and bottom tracer wheels copy the contours of the panel and guide the trimmer. The problem with using this technique for pre-drilled panels is that when the tracer wheels come upon a hole, the wheels will dip into it and treat it as a variation in the thickness of the panel rather than a hole to be ignored. This results in too much material being trimmed from the edge adjacent to the hole and creates a scallop on the edge.

Some furniture manufacturers get round this issue by inserting a plug into each hole, but this ‘stop gap’ solution is less than ideal. Not only is it time consuming, it is also virtually impossible to achieve an exact height match between the panel and the plug so there is always an impact on edge-banding quality.

What is the solution?

With Biesse’s Pro Nesting option, pro nesting copiers are fitted to the top profile trimming unit and profile scraping units. In addition to the large diameter tracer wheel, there are two further wheels to the left and right of the main tracer wheel. By having three points of contact with the panel, even if one of the wheels encounters a drill hole, the other two wheels will keep the cutters and scrapers in the correct position and prevent them from deviating. This simple but highly effective solution guarantees high quality edge-banding for pre-drilled panels.

Discover the full edgebanding range here.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil