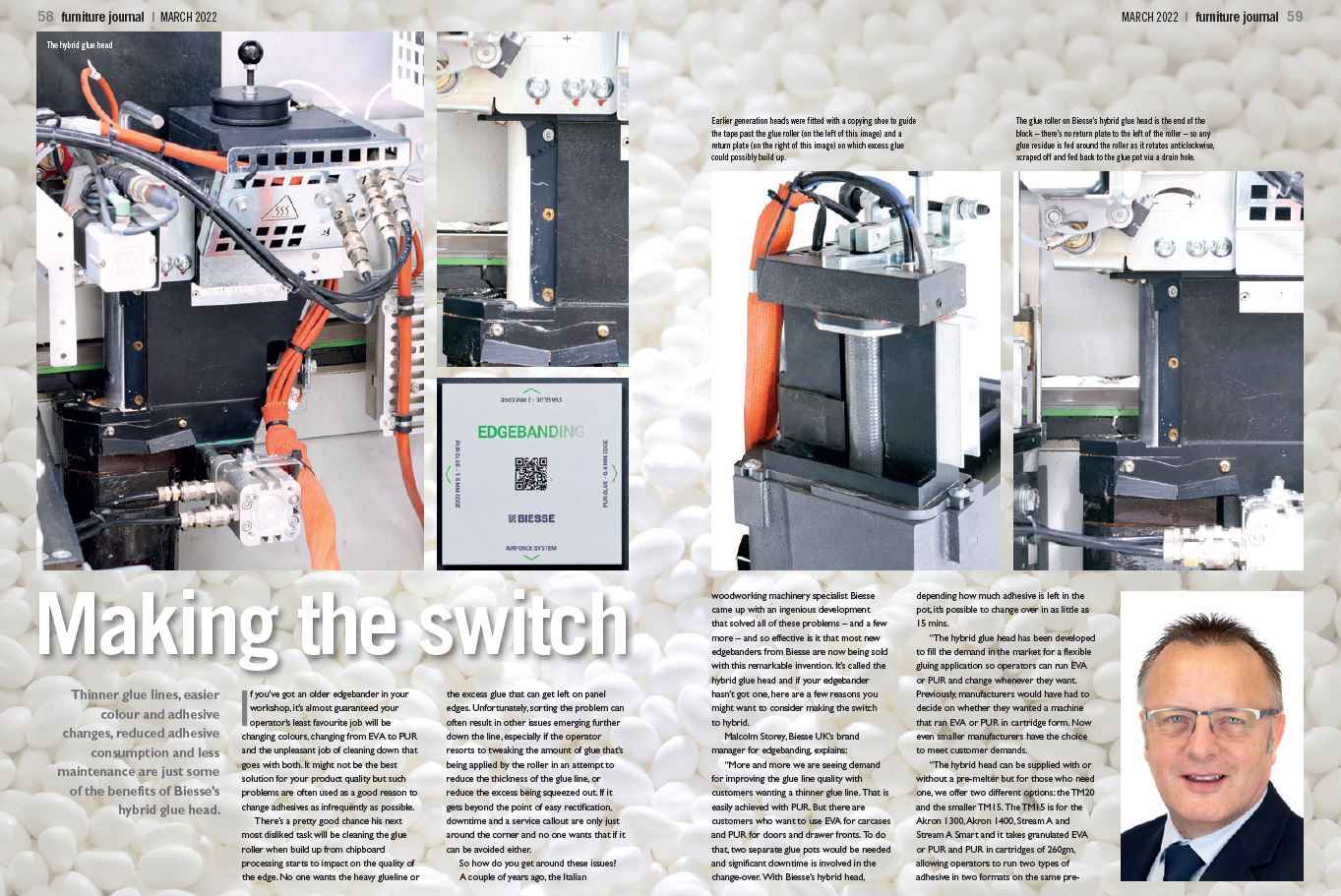

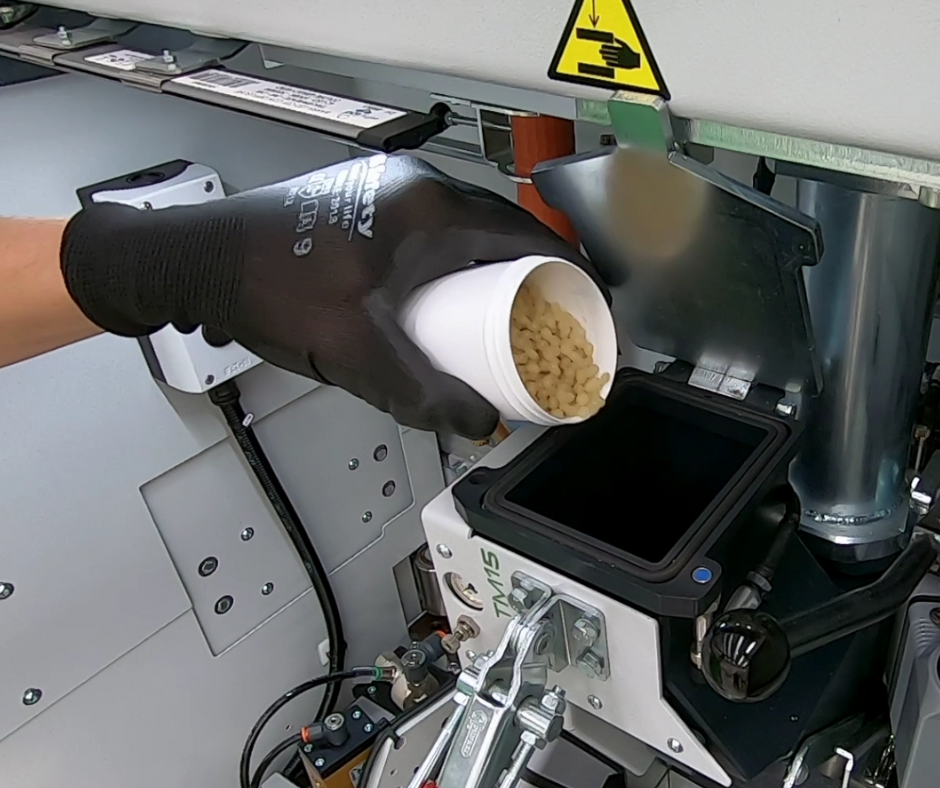

Thinner glue lines, easier colour, and adhesive changes, reduced adhesive consumption and less maintenance are just some of the benefits of Biesse’s hybrid glue head.

If you’ve got an older edgebander in your workshop, it’s almost guaranteed your operator’s least favourite job will be changing colours, changing from EVA to PUR and the unpleasant job of cleaning down that goes with both. It might not be the best solution for your product quality, but such problems are often used as a good reason to change adhesives as infrequently as possible.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil