Biesse has pioneered solutions for sanding, calibration, and planing of timber-based sheet materials such as blockboard. Our sanding experts will recommend the optimal machine configuration for each customer with the aim of achieving target material removal within the minimum number of passes.

Calibration: know your rollers

Most sanding machines will incorporate at least one roller unit. The core of the roller is always steel, but the coating can be made from a variety of materials - from steel to hard or soft rubber. For calibration, very hard rollers such as steel, 60SH or 90SH rollers are recommended, whereas softer, more forgiving 20SH or 40SH rollers are better suited to sanding. Calibration rollers also have a smaller diameter than sanding rollers, with good reason: concentrating the pressure on a small surface area allows more material to be removed without applying excessive force. This is important, because generally, during calibration, machine operators are looking to remove up to 0.5mm.

To buy or not to buy calibrated panels? That is the question…

Where manufacturers need to remove more than 0.5mm, it is time to look at a planing unit rather than a roller unit. Removing larger amounts of surface material with a roller unit requires several passes, impacting productivity. A planing unit, by contrast, is a far more efficient way of removing extreme amounts of material - up to 3mm can be shaved off in a single pass.

Whether or not the case for a planing unit adds up will depend on where the company is in the value chain and the quality of the wood they are buying. Unprocessed panels can be very rough, requiring removal of 2-3mm of material to eliminate variability. Companies will need to do their own calculations to establish whether it makes more sense to spend on a planing unit and buy cheaper uncalibrated panels or buy more costly calibrated panels that do not require planing. As the price of timber continues to rise, shorter payback periods are contributing to an increasingly compelling case for investing in planing capabilities.

HPG: the benefits are ‘plane’ to see

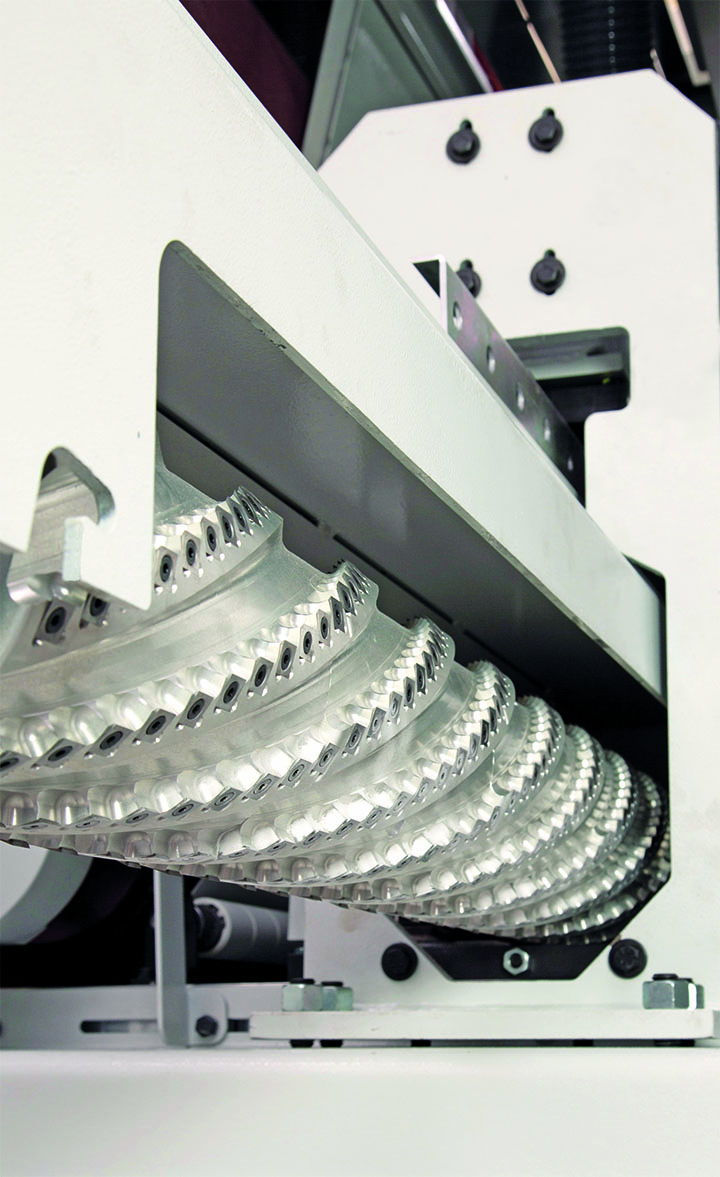

Biesse’s solution for extreme material removal on solid wood panels is a planing unit with a helical profile and durable tungsten cemented carbide cutting inserts. The helical design promotes non-aggressive contact with the panel, preventing over-calibration and splintering and ensuring an even surface finish. The cutting inserts are square-shaped to prolong the life of the unit - each insert can be rotated 90 degrees when worn rather than having to be replaced.

Pressure shoe stamps out inconsistencies

Key to the performance of the HPG planing unit is Biesse’s pressure shoe feature. This simple but ingenious device comes into its own when the panel being processed is warped or has significant variations in thicknesses. As the name suggests, the sectioned pressure shoe applies pressure across the panel, pushing it down to eliminate variations in thickness and ensure even calibration across the width of the panel. Without this feature, what tends to happen is that the planer removes too much material from some areas of the panel (usually the sides) and not enough from others (usually the centre). A secondary benefit of the pressure shoe is that it extends the life of the cutting inserts - without this feature they would wear out more quickly and at different rates.

Programmed for productivity

Operation is simple and intuitive - the user selects the target thickness based on the machine’s assessment of the panel’s dimensions. Up to 3mm can be removed in one pass. If more than 3mm needs to be removed to achieve the target thickness, the machine can be programmed with two passes. The unit also incorporates a preset removal function which instructs the planer to remove a set amount of material regardless of the panel’s thickness. This dramatically increases production speed as it eliminates the need to measure every single panel. It is particularly useful where two passes are required, as the first, less critical pass can be carried out quickly.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil