We simplify your manufacturing process to make the potential of any material shine.

01 August 2021

An Edge on Quality

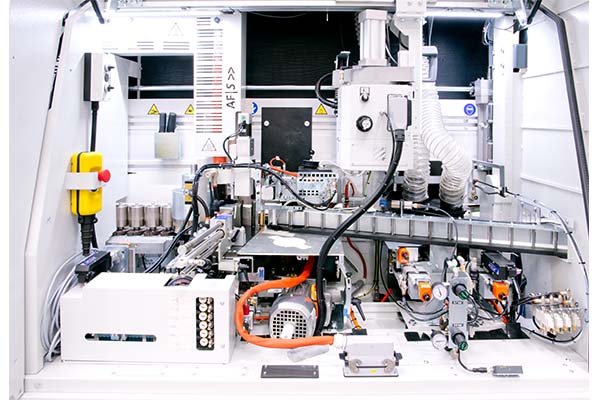

The only true way to get zero glue line is to use an Airforce-type machine that releases the functional layer on a laser tape with heat.

The big plus from a customer’s perspective is that you can clean the glue head on the machine.

If you are running MFC you need more adhesive than if you are running MDF because the adhesive is absorbed into the core of MFC. On Biesse machines, it’s possible to write a program for the different board material you are using that regulates the glue dosage automatically.

You can get a much thinner glue line with PUR than with EVA but people have always been wary of PUR because of the internal housekeeping that was needed to get a good finish. We’ve taken that problem away from the customer.”

A further contribution to improved glue lines is Biesse’s Pro-Glue kit. This clever little device locks the copying movement of the hybrid or standard glue head so when the panel leaves copying the glue roller assembly doesn’t move forward.

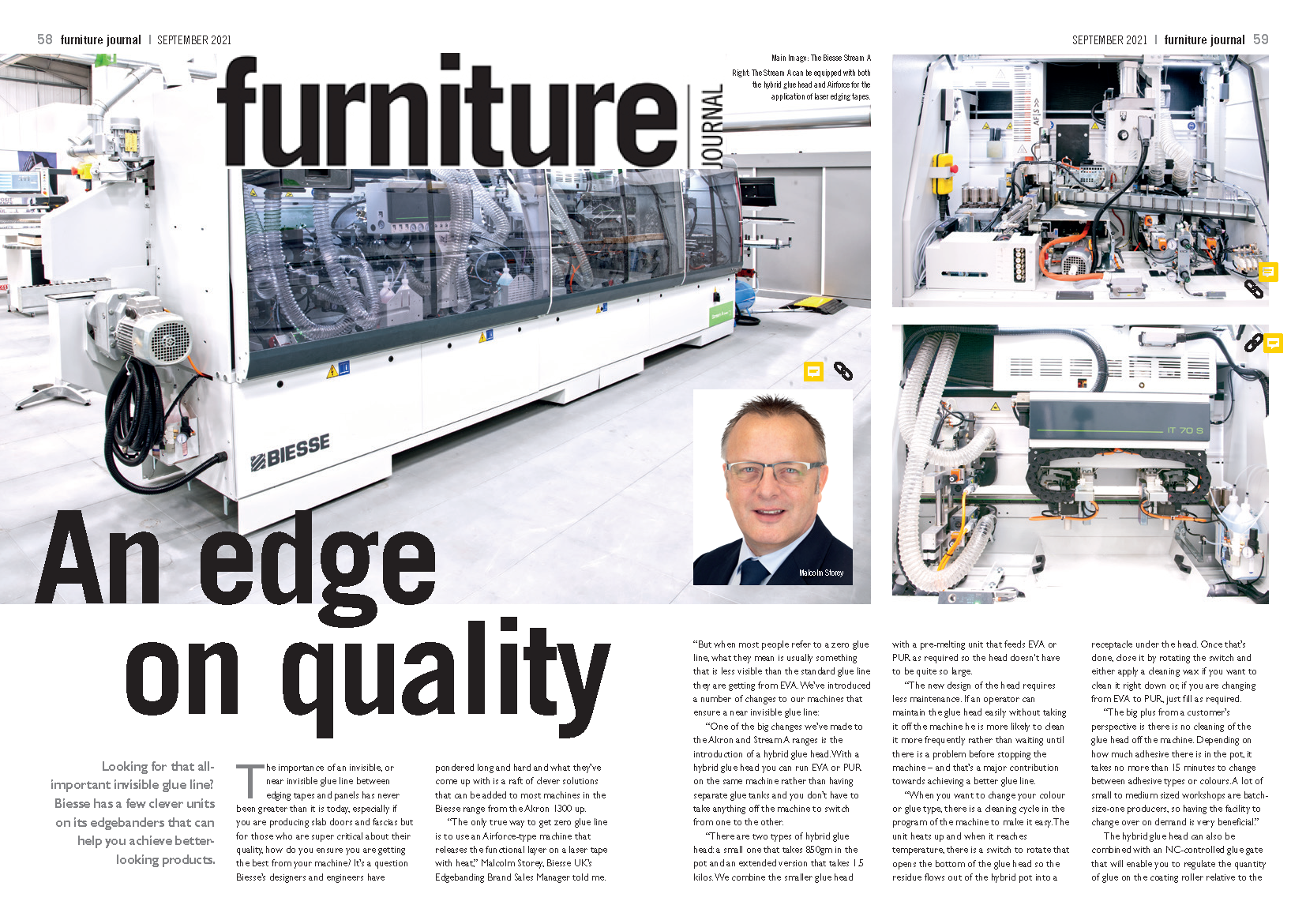

Of course, you could go the extra mile, move to laser edging tapes and eradicate the glue line entirely with Biesse’s Airforce system. More manufactures are wanting a combination of Airforce and the hybrid glue head on their straight line edgebanders so they can run EVA, PUR and Airforce.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil