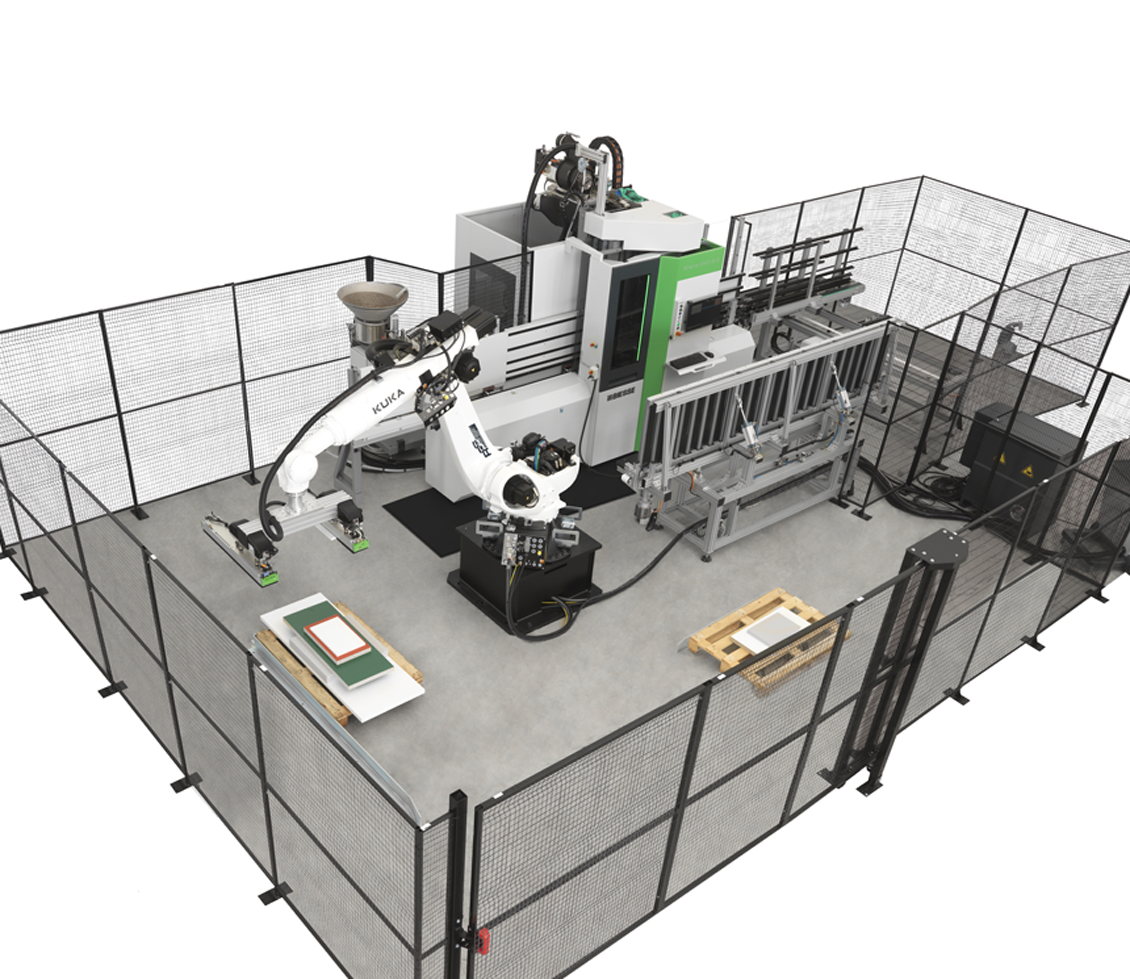

High versatility in accordance with production needs

Brema Eko 2.2 is the new compact and versatile vertical boring machine with reduced footprint, for machining panels of different thickness and sizes. The ideal solution for “just in time” production, even for the most complex routing machining processes.

We simplify your manufacturing process to make the potential of any material shine.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil