We simplify your manufacturing process to make the potential of any material shine.

We simplify your manufacturing process to make the potential of any material shine.

Biesse offers its customers pragmatic solutions for factory automation.

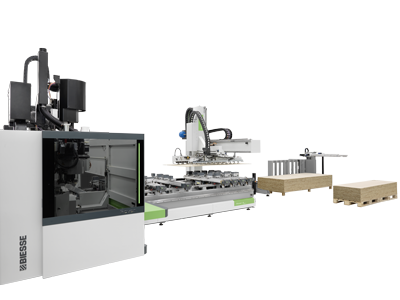

ROS robotised solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

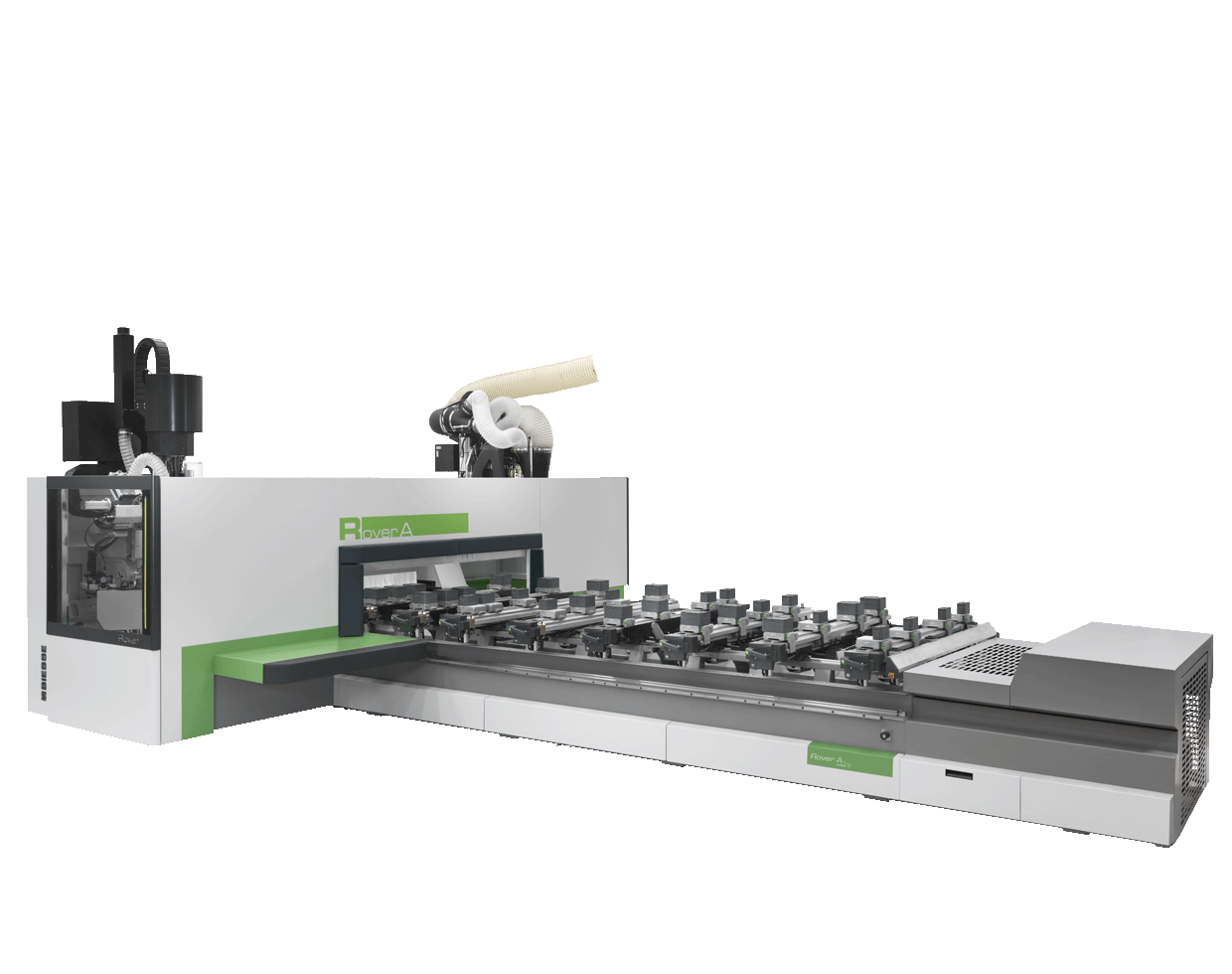

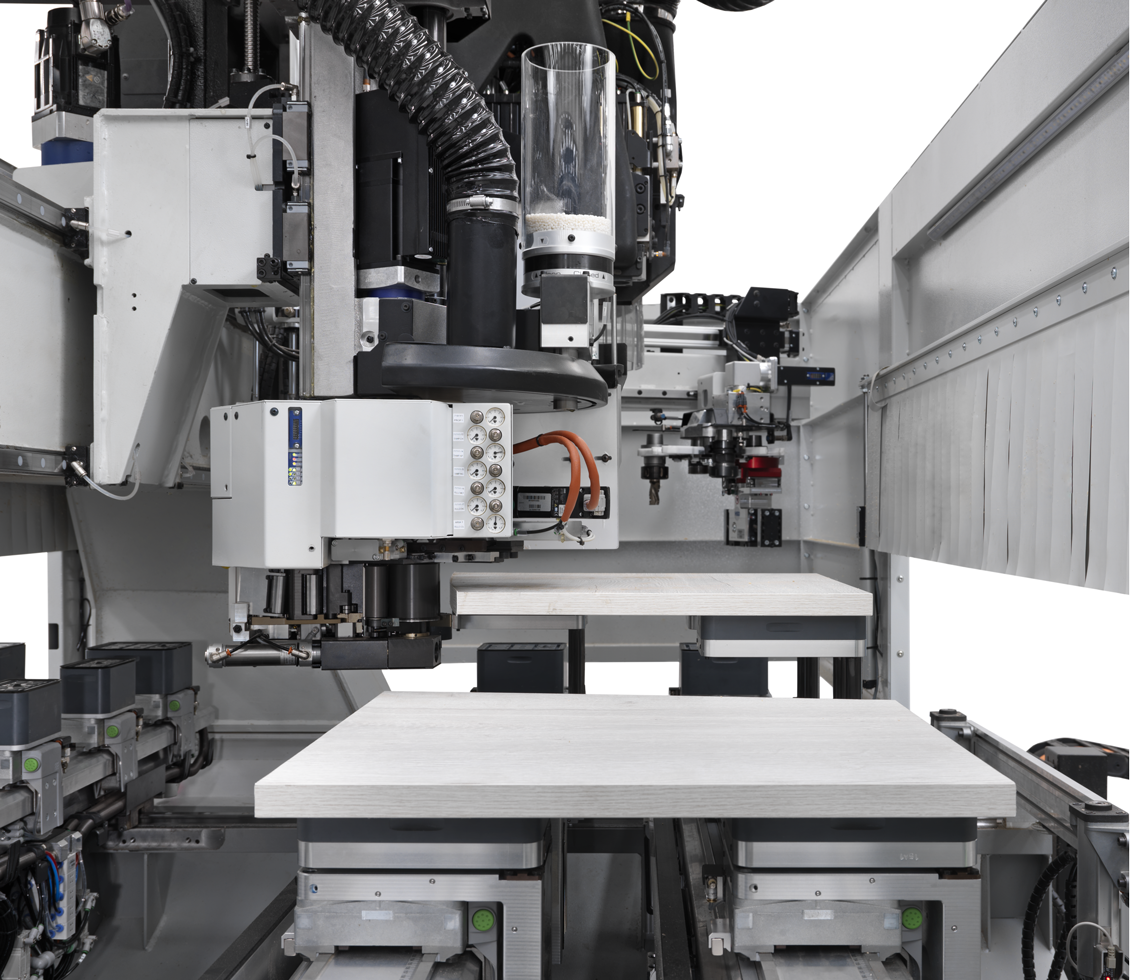

It is the innovative positioning system that allows you to exploit the worktop in height.

The Hyperpods allow, by lifting the pieces that make up a program, to perform processes that were previously only possible on machines with greater width.

New hybrid system for melting on-demand glue from above:

- Hybrid pre-melter for working PUR, EVA or APAO glue, to meet every possible need

- High flexibility thanks to the possibility to use glue either in granules or in small cartridges

- Quick and easy maintenance procedures

.png)

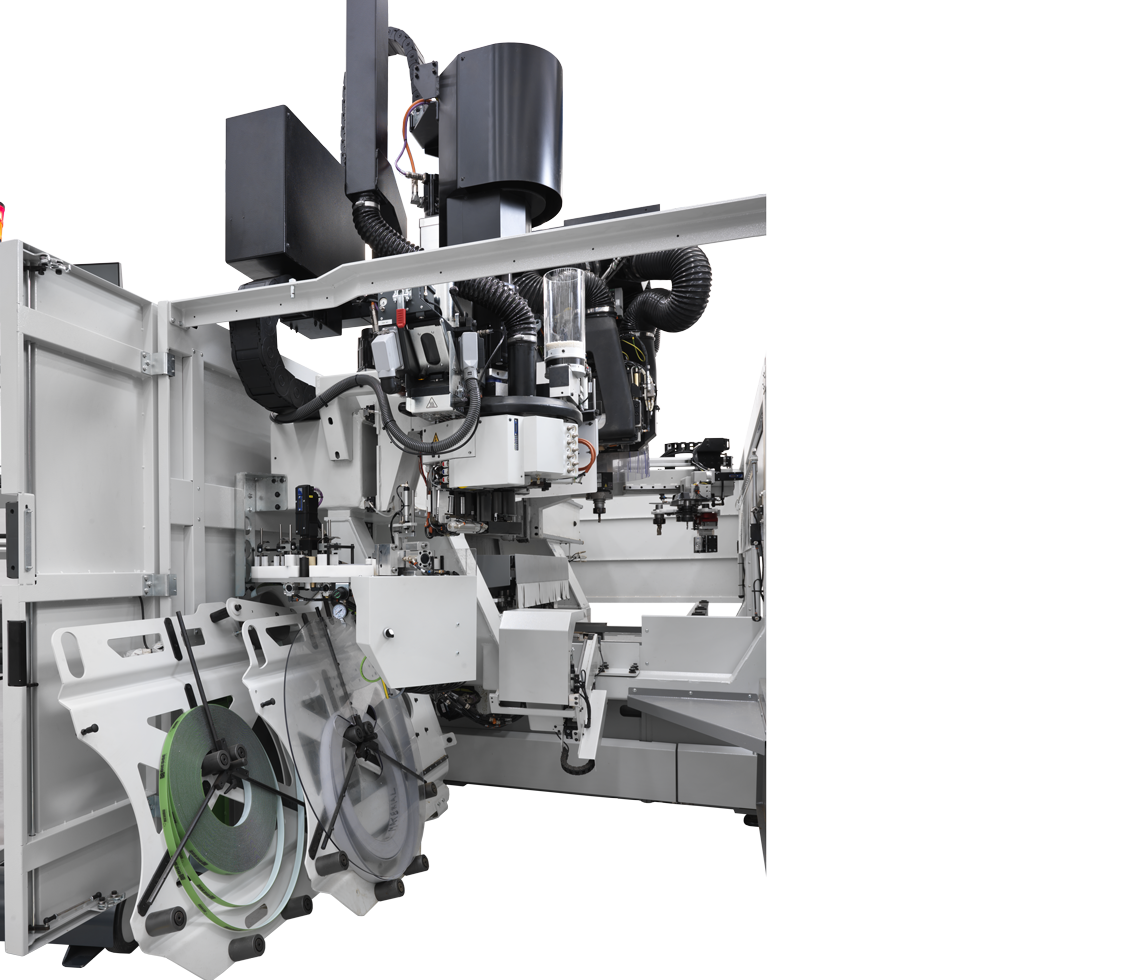

Loading and unloading solutions. Automated cell for machining a batch of panels or doors.

Synchro is a loading/unloading device that transforms the Rover machining centre into an automatic cell for producing a stack of panels autonomously without the need for an operator: