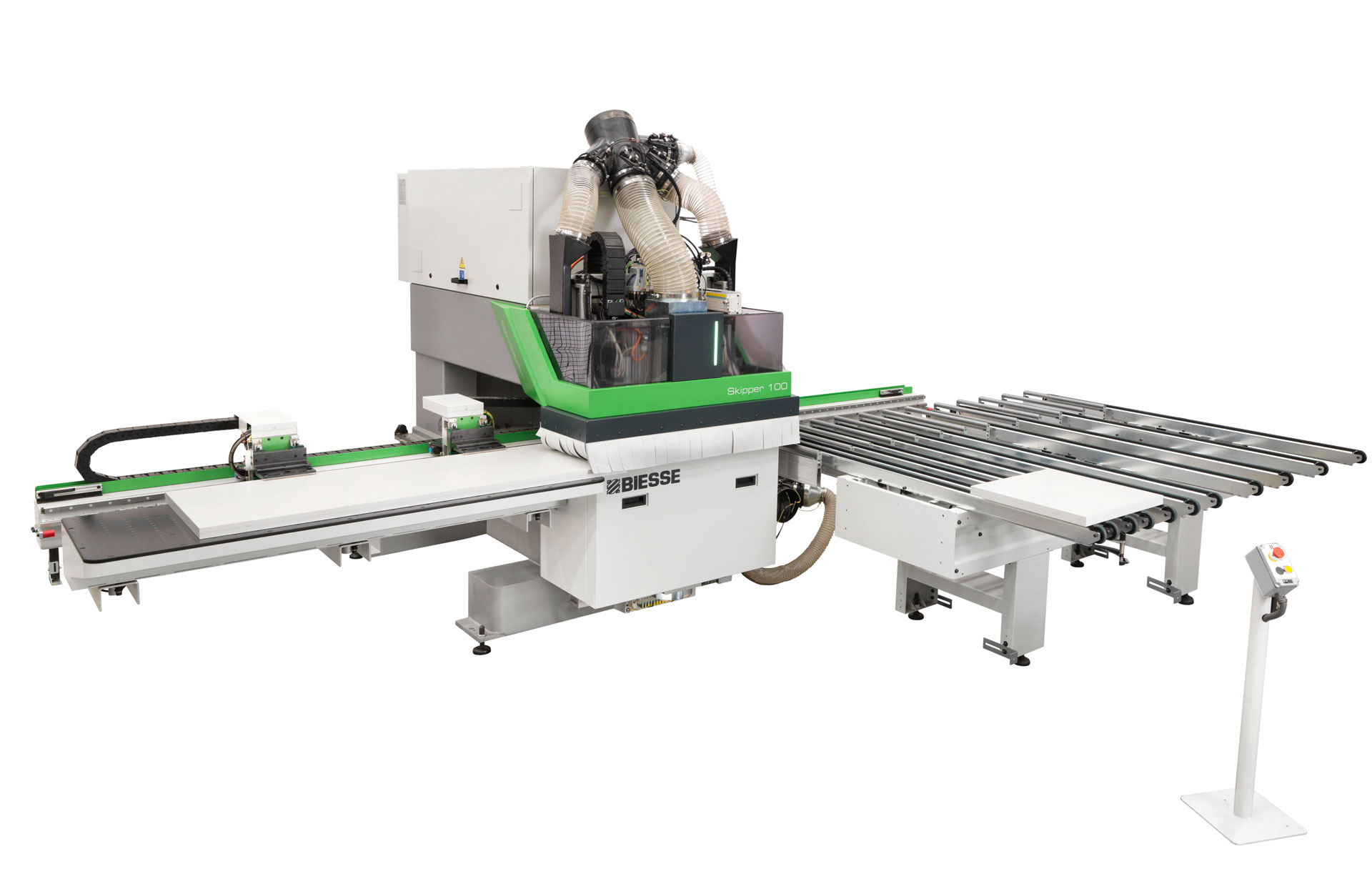

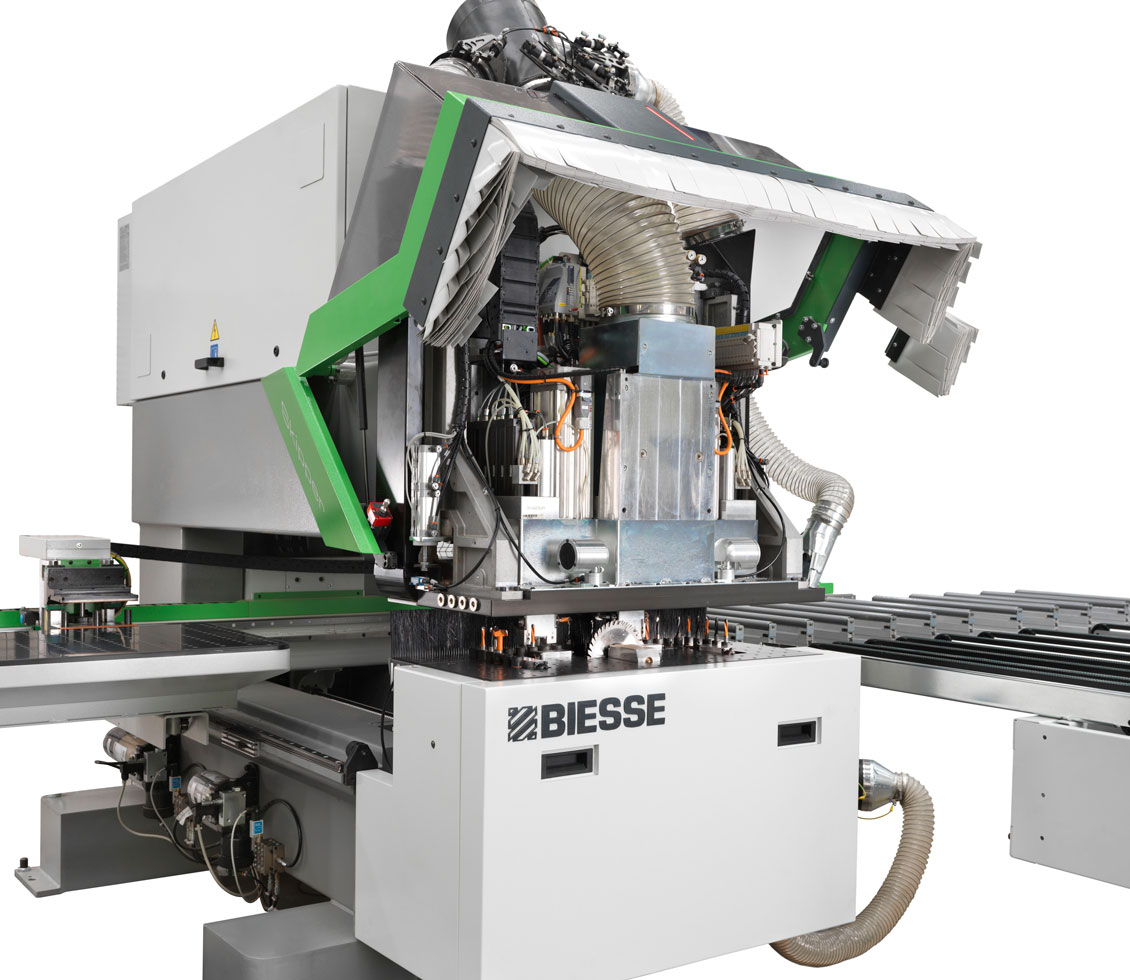

TOP RESULTS WHEN MACHINING TWO PANELS SIMULTANEOUSLY.

Skipper 100 is the innovative numerical control processing centre that can process panels

of different formats in sequence and in “real

time”. It's ideal for the non-standard production

of large companies where personalisation becomes the norm, for producing small batches

for third parties, and for those requiring just-intime flexible production.

İşlediğiniz tüm malzemelerin potansiyelini en iyi şekilde ortaya çıkarmak için üretim sürecinizi kolaylaştırıyoruz.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil