Stay up to date on Biesse's full range of high quality woodworking machinery!

As your exclusive local representative for the Biesse product line in the State of Arizona, Jerry Gordon, President of Red Rock Machinery, wants to keep you up to date on the wide range of machinery solutions we have available.

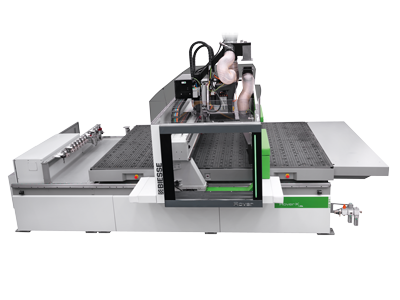

Our product offering includes cutting edge machinery for manufacturing panels, solid wood, plastics, composites and advanced materials, along with new software modules. From entry level machines to integrated lines with robots and automation, we offer price competitive solutions for all levels of manufacturing and production.

Some product highlights include Viet Wide Belt Sanders and automated sanding solutions with the new Sculpture Pad for effect sanding, CNC Routers, 3 Axis, 4 Axis and 5 Axis machining centers, small to large edgebanders with a variety of options such as an EVA Pre-Melting unit as well as the award winning AirForce Hot Air System and Biesse's new groundbreaking TM10 PUR application system, Drilling Machines, CNC Panel Saws, plus much more.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)