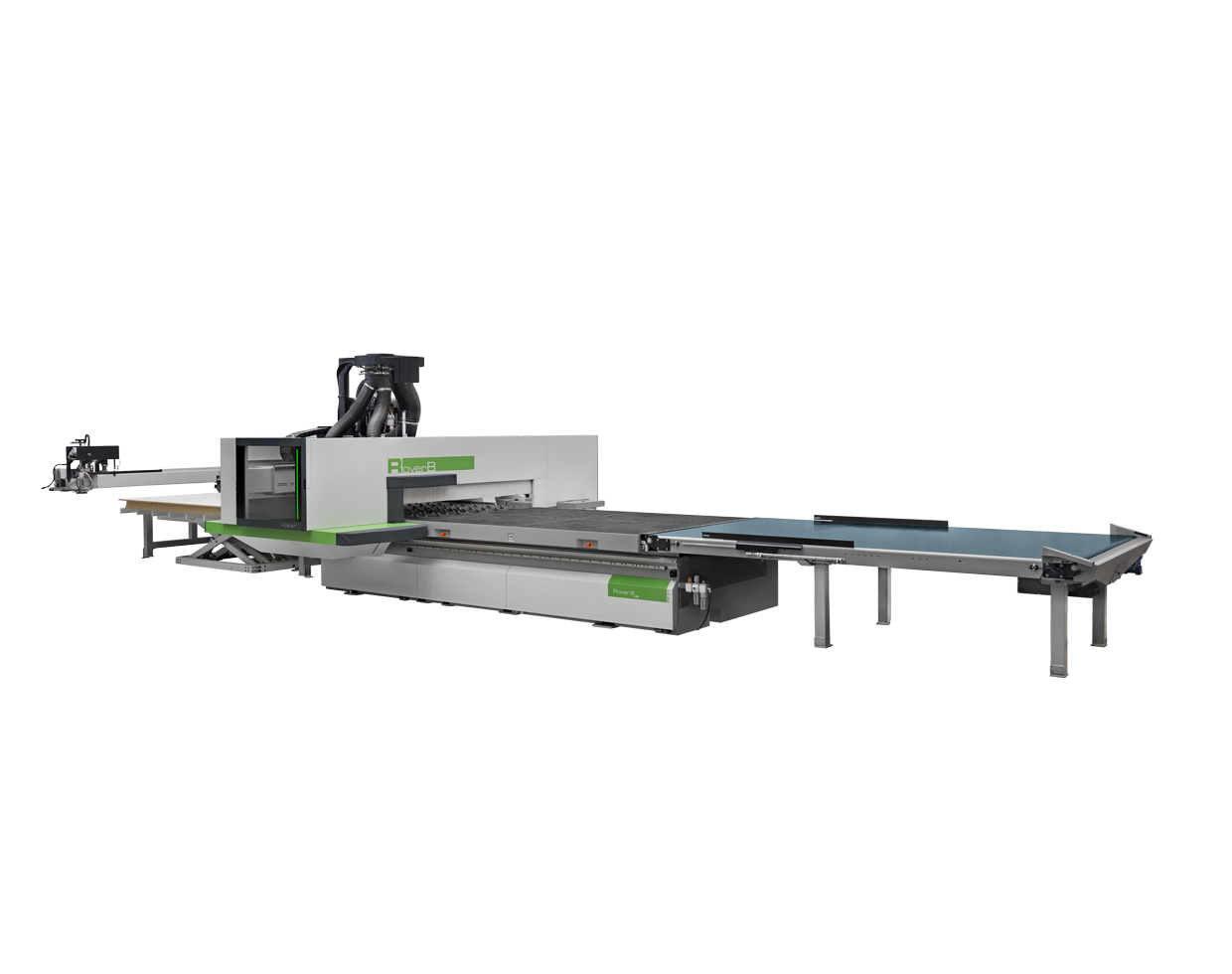

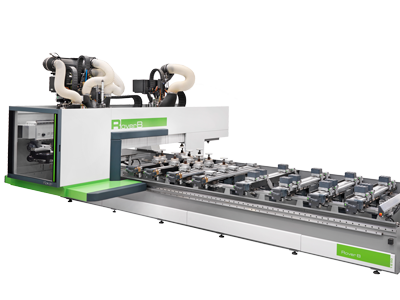

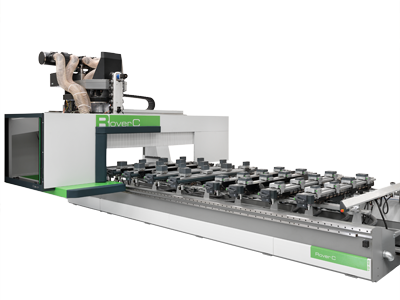

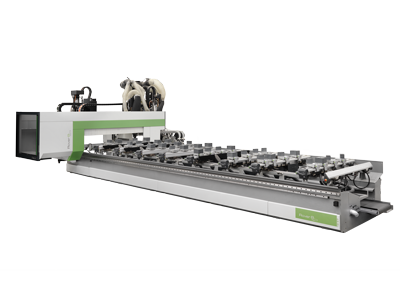

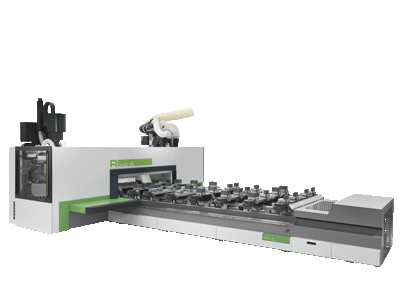

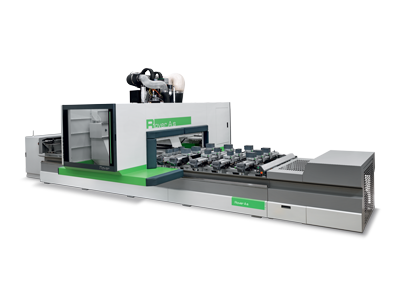

the quality and productivity standards in this

sector. Thanks to its structure and the variety of

possible configurations, it can keep abreast of

the work rhythm of medium and large companies

for the production of pieces for every type

of application.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

.png)

_400x300.png)