It is ideally suited to small and large joineries that need to manufacture either odd size products or standard size products in small batches.

Biesse offers its customers pragmatic solutions for factory automation.

ROS robotized solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

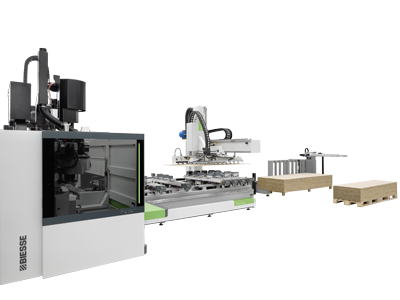

Loading and unloading solutions. Automated cell for machining a batch of panels or doors.

Synchro is a loading/unloading device that transforms the Rover machining centre into an automatic cell for producing a stack of panels autonomously without the need for an operator: