We simplify your manufacturing process to make the potential of any material shine.

We simplify your manufacturing process to make the potential of any material shine.

Biesse offers its customers pragmatic solutions for factory automation.

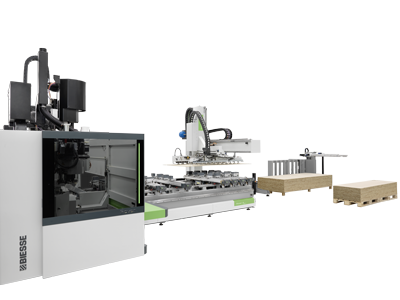

ROS robotised solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

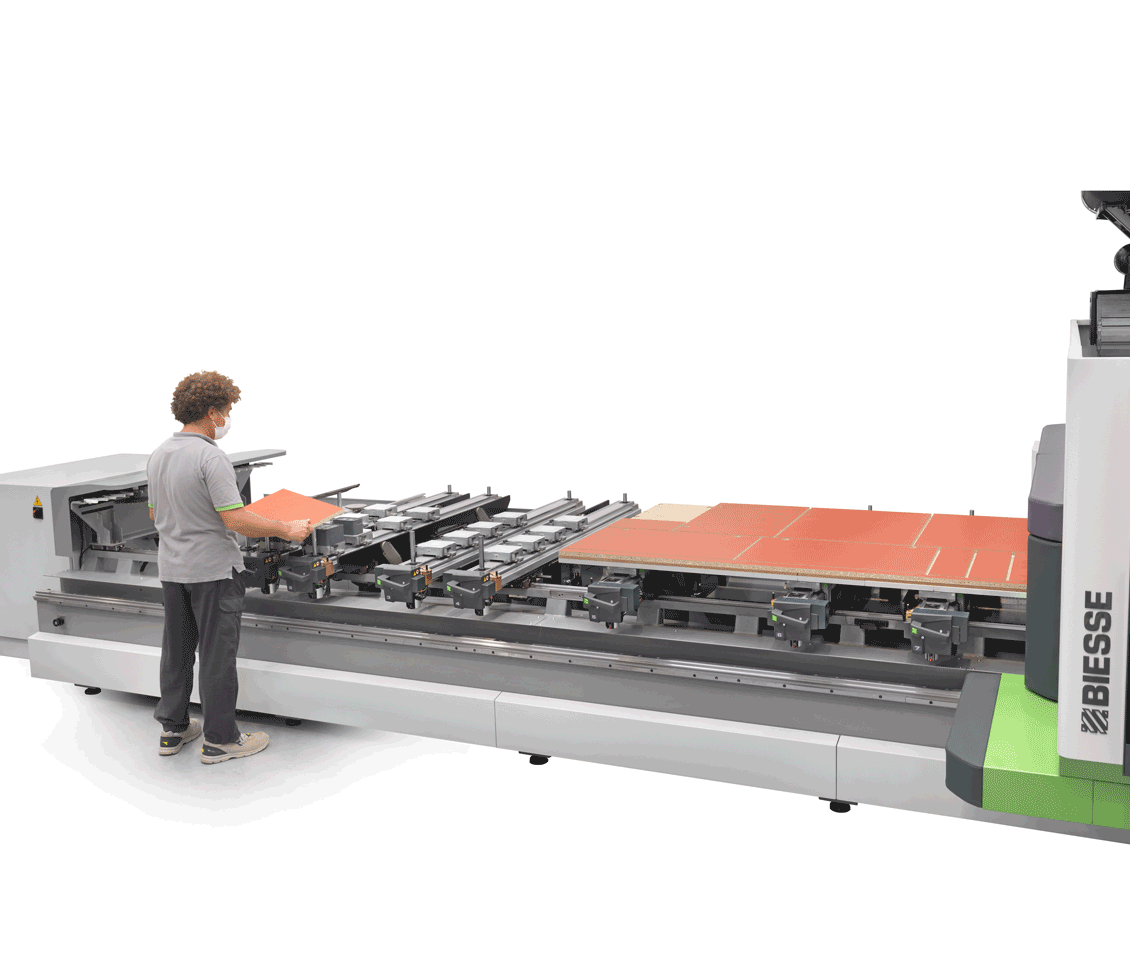

Loading and unloading solutions. Automated cell for machining a batch of panels or doors.

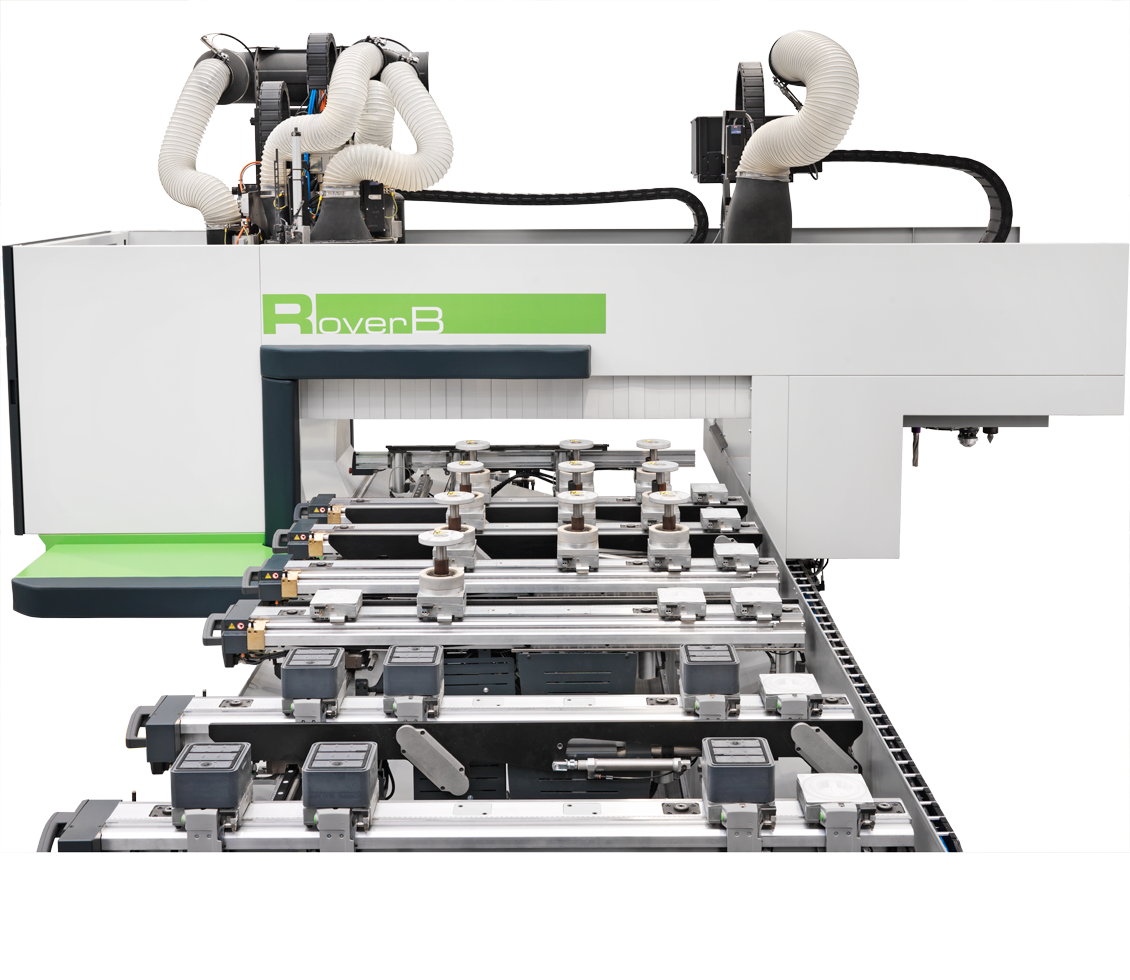

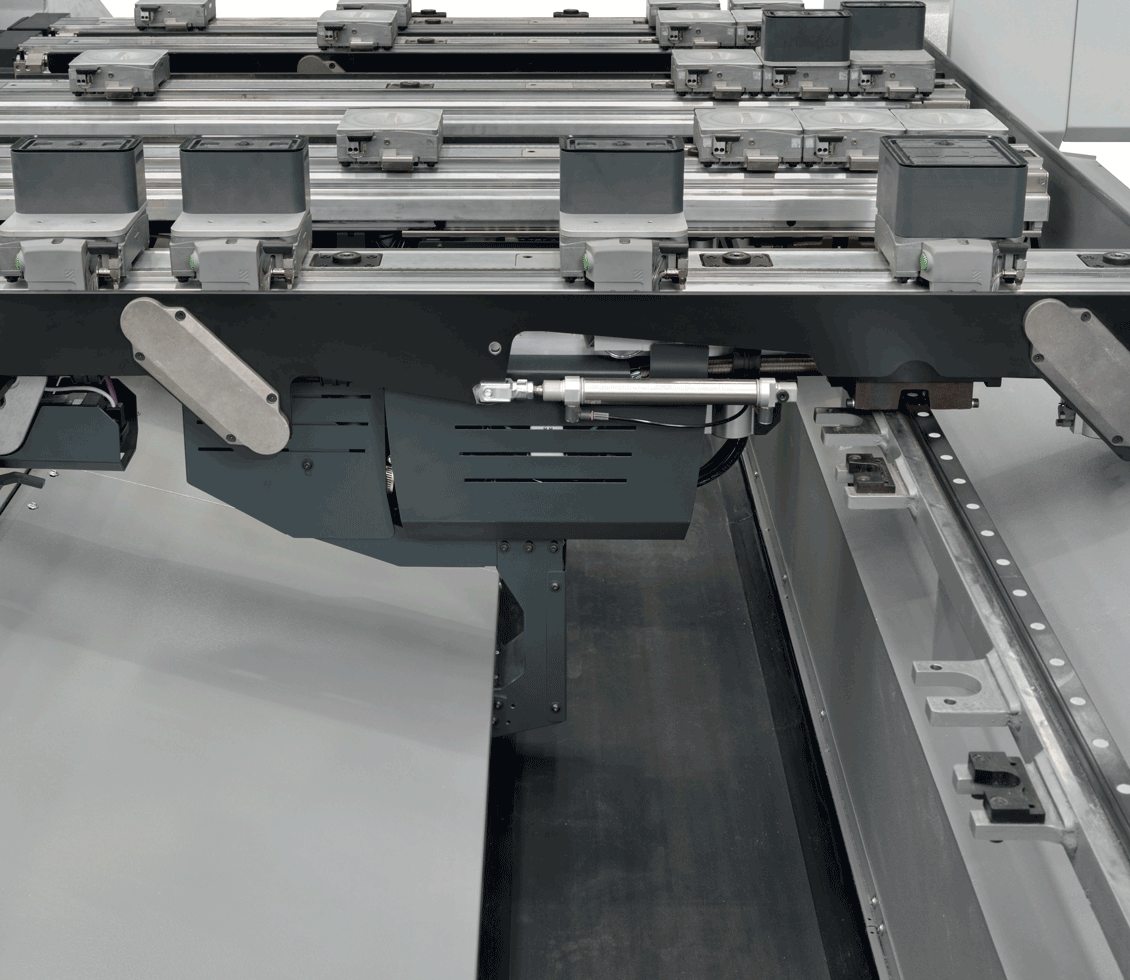

Synchro is a loading/unloading device that transforms the Rover machining centre into an automatic cell for producing a stack of panels autonomously without the need for an operator: