We simplify your manufacturing process to make the potential of any material shine.

Dynamic design gets smart.

They call it digital material, a witty description for a material with the following composition: two layers of wood coupled with a central layer of textile. The result, as innovative as it is revolutionary, gives a tangible shape to masterpieces of creativity and dynamism - infinite combinations of architectural shapes and forms with an artisan touch and a metropolitan flavour. Giulio Masotti, CEO and co-founder of Wood-Skin - a startup founded in 2013 with three partners Stefano Baruffaldi, Susanna Todeschini and Gianluca Lo Presti - came up with the idea, which would go on to become a patented industrial process and serve a specific purpose, "to achieve complex forms in a simple and economical manner, both in terms of the surroundings being created and of the design itself," as the team from Milan explains. Necessity and experimentation merged and resulted in new words that have the ring of a mantra: “smart materials” and “smart machines”. A smart combination, with the aura of a prodigious fellowship, outlined by Giulio Masotti, a man who skilfully manoeuvres amid new challenges and never before seen trends and who has made previous contributions toward a multi-sensory future.

Innovation, technology, creativity: Biesse and Wood-Skin share a strong identity and a common vocation, and came together to share their experience at Ventura-Lambrate, during the Salone del Mobile. «We wanted to explore the potential for working together in the future, with smart materials such as Wood-Skin and our shared passion for innovation. With the assistance of MIT Boston, we launched a collaborative project, which is both experimental and yet extremely practical: the Programmable Table. This new concepts embodies the vision of a future where items of furniture will be able to self-assemble once completed by the machine that produces them. This is not merely a prototype, but rather a concrete result which will give rise to a line of products in the not-too-distant future».

This scenario may seem futuristic, but in reality, it is extremely practical, if supported by a suitable level of expertise which is able to give shape to ideas, in a simple and straightforward manner. Like the Excel machining centre by Biesse. «The centre is extremely precise, versatile and efficient, allowing us to implement our patented process by performing an unlimited number of precise and complex machining operations. This, when combined with an innovative material like Wood-Skin, can produce a range of unusual, unconventional results. Biesse machines allow us to change the state of the material itself and transfer wood and other materials from a solid state to a digital state, in which the material becomes intelligent and is ready to take on other forms, once it has been removed from the machine».

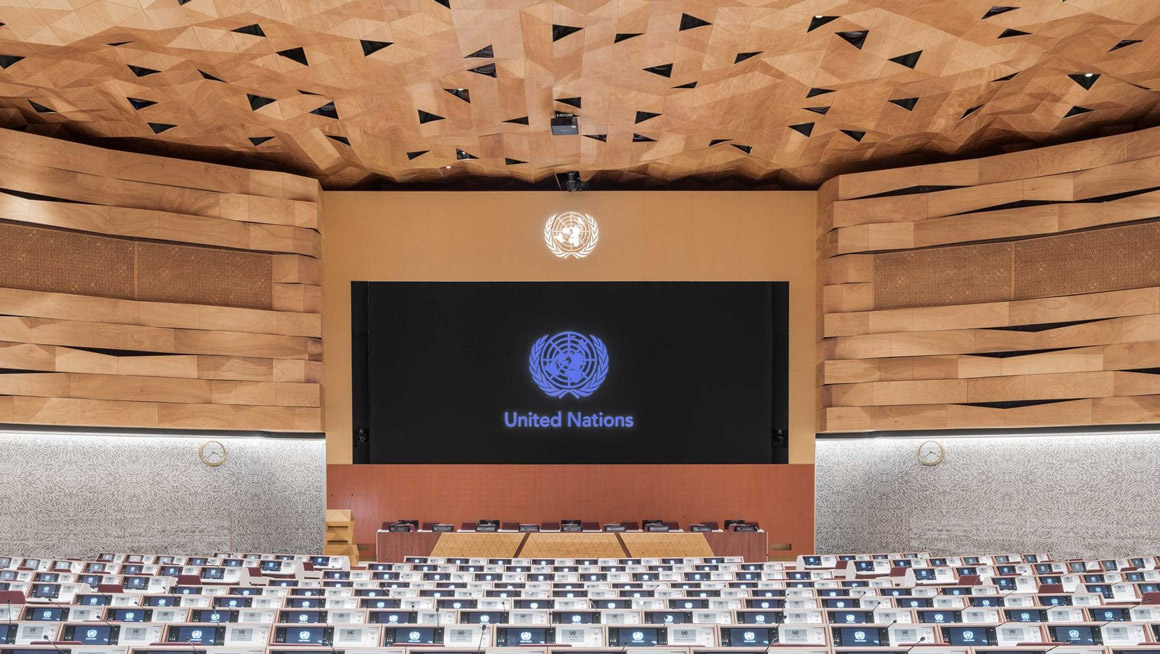

Six years have passed since they first came out with a completely original product "back" in 2013. What has happened since then? "Wood-skin is now a company with an internationally recognised patent that ships its goods all over the world through an increasingly dense network of agents and distributors. We structured the company with one project after another, aiming to offer an increasingly complete product and service for our customers, architects and general contractors who are searching for new solutions, new shapes and new technology. Wood-Skin now consists of 20 people, architects, engineers and computational designers who provide expert advice about how to use and develop our solutions for 3D surfaces across a very diverse array of projects. We continue to operate mainly in interior design, but we are taking important steps toward the outside, where large and important projects await. Our hope was that architects and designers would help us find ways to exploit the market potential of this rigid textile, and fortunately that's what happened. Six years later we have completed dozens of projects all over the world and have seen Wood-Skin receive official recognition as a leading technology for the creation of complex 3D surfaces, thanks to a project that was very significant and iconic for us: in August, in fact, the renovation of hall XIV at the UN in Geneva will be completed by the Peja Associati studio of architecture. And they selected Wood-Skin to create the biggest free-form suspended ceiling in the world!".

Parametric modelling, generative design and artificial intelligence are opening up a world of shapes and optimisations that were unimaginable just a few years ago.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil