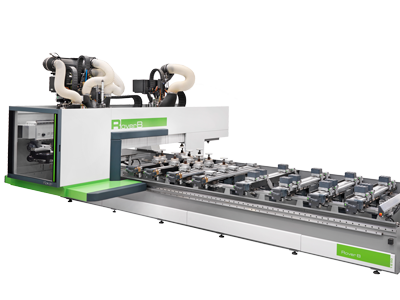

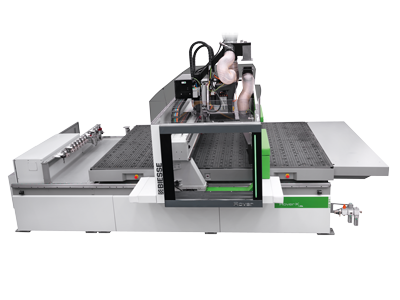

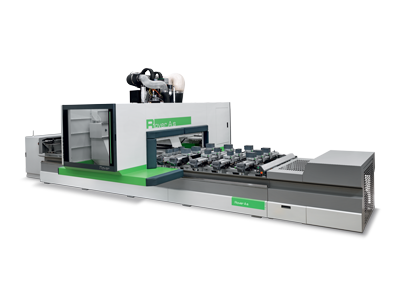

ROVER B

Rover B is the machining center aimed at the advanced craftsman and large industry, designed for panel, solid wood and heavy machining in general.

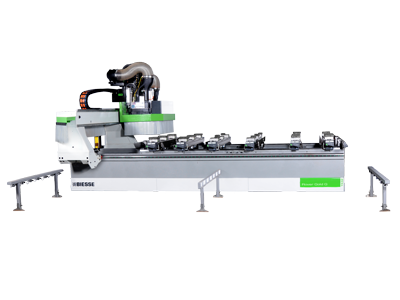

ROVER GOLD G

The CNC processing centre designed for craftsmen who need to automate their production process as well as smallmedium enterprises that specialise in custom made products.

ROVER GOLD

The compact machining centre designed for high performances capable of meeting various levels of production requirements

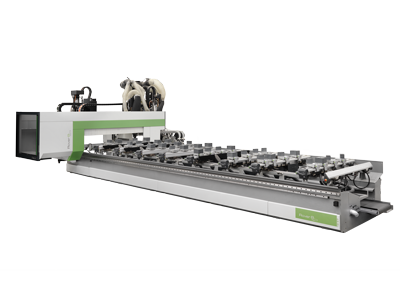

ROVER K SMART

The numerical control machining centre for artisan and small to medium sized businesses looking for simple solutions at affordable prices.

ROVER A SMART 16

The simple, userfriendly 5-axis NC processing centre for producing any type of furnishing item

ROVER A 16

The CNC processing centre for the manufacturing of furniture and window/door frames

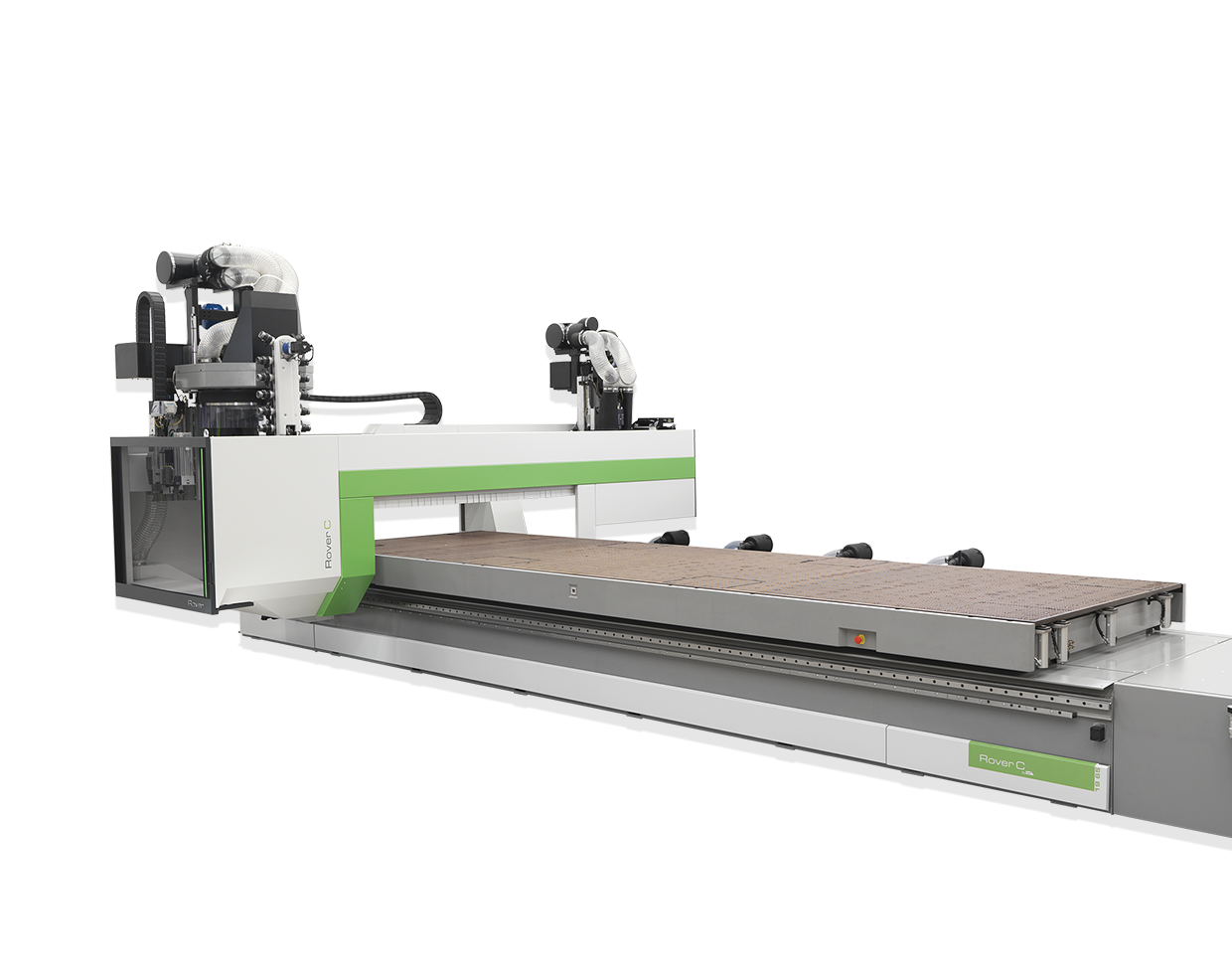

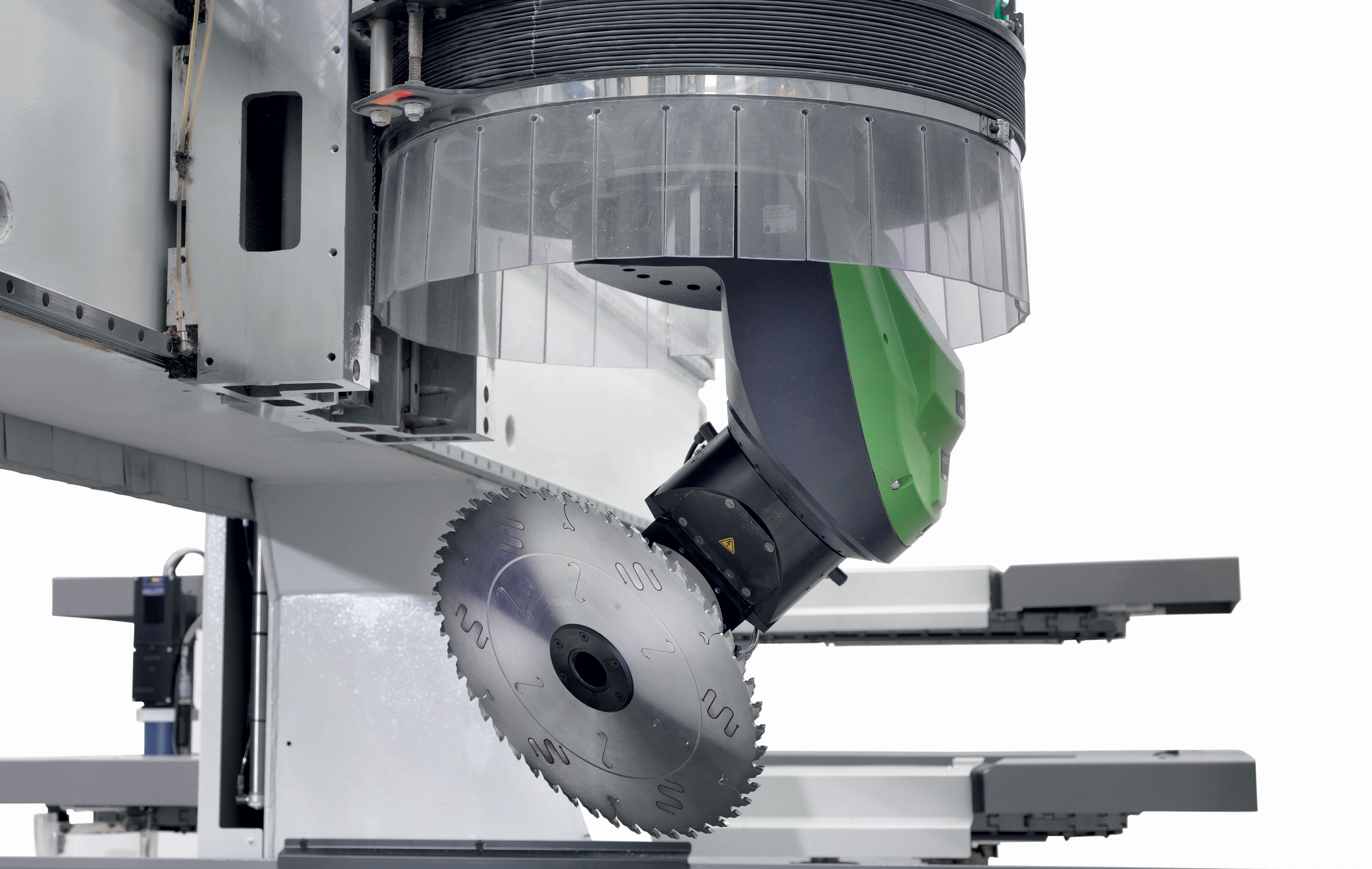

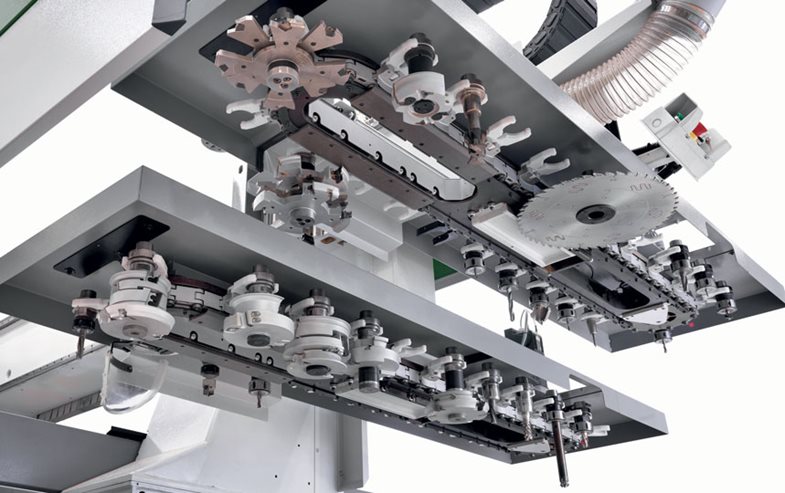

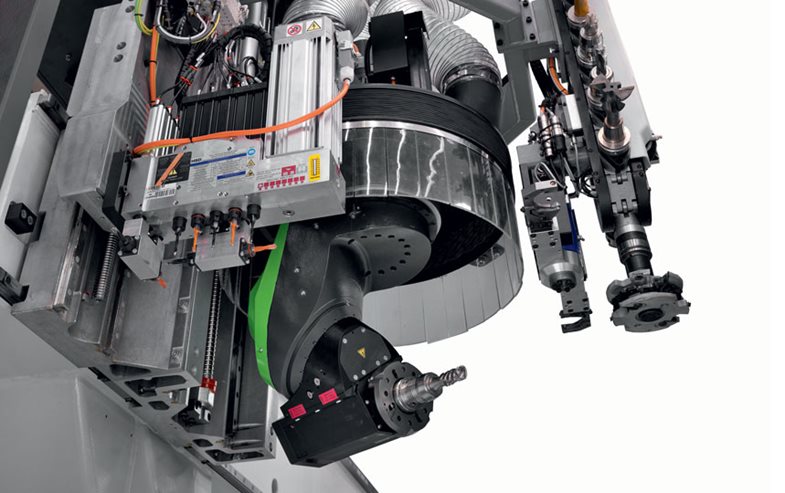

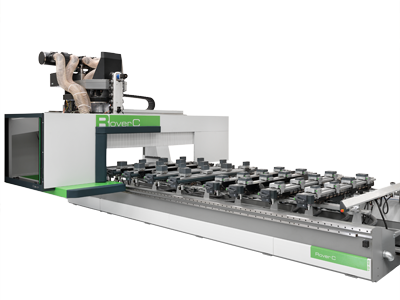

ROVER C

The new processing centre for manufacturing furniture, staircase and door and window components of any shape, size and thickness with ease

ROVER A EDGE 16

An edgebanding machining centre that supports the machining of shaped panels, which can be edgebanded on a single, compact, high performance machine

ROVER B EDGE

Edgebanding machining centres from the Rover B Edge range allow users to carry out machining operations to shape and edgeband panels on a single machine.

ROVER K FT

Easy and compact machining center for high quality NC nesting production.

ROVER A FT

Rover A FT is the new high-performance machining centre for Nesting operations. Compact and efficient, with a gantry structure, the Rover A FT offers top-of-the-range technology and guarantees optimum precision in every machining operation.

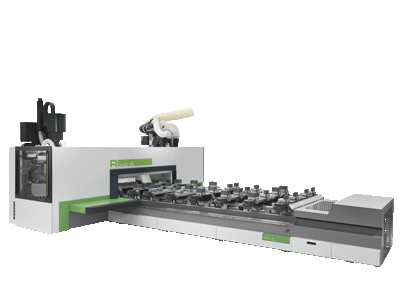

ROVER A

Rover A is the flexible new high-performance NC machining centre with a gantry structure, designed for customers who want to invest in a product that can process any type of element quickly but with excellent results.

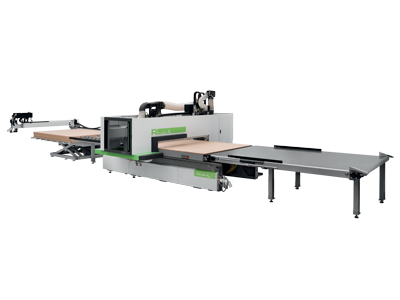

ROVER B FT

The Rover B FT nesting machining centre raises the quality and productivity standards in this sector. Thanks to its structure and the variety of possible configurations, it can keep abreast of the work rhythm of medium and large companies for the production of pieces for every type of application.

ROVER A EDGE 15/18

Rover A Edge15/18 is the new edgebanding CNC centre with a gantry structure, designed to produce shaped, edgebanded panels on a single machine.

ROVER AS 15

Rover AS 15 is the new NC processing centre offering top performance and flexibility. It’s designed for the customer who wants to invest in a product that can process any type of element quickly and economically.

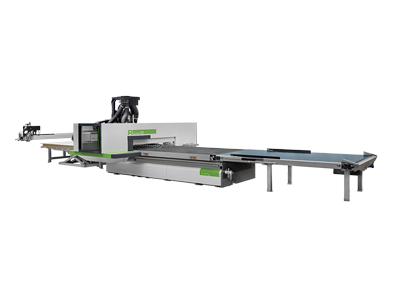

ROVER B FT HD

Rover B FT HD is the new Biesse high performance machining centre dedicated to nesting operations. Designed for high speeds and optimum accelerations, it takes its position as most productive machine on the market.

Rover AS FT

Rover AS FT is the machining centre for Nesting operations designed for the customer who wants to invest in the growth of their business and the evolution of the production process, obtaining high performance and productivity.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

_400x300.png)