MECSPE returns, the biggest trade show in Italy dedicated to innovation in the manufacturing industry. Biesse – PAV. 16, STAND E34 – will be presenting the latest technology based on innovative developments specific to the field of machining operations for plastic and composite materials: the new numerically controlled Rover Plast K FT work centre.

MECSPE 2021

MECSPE, with 92,000 square metres of exhibition space, 18 pavilions, 13 halls, 46 special events and conferences, and more than 1,960 exhibiting companies, is the primary manufacturing trade show in Italy, taking place from 23 to 25 November and this year making its début in Bologna's exhibition district with a new exhibition space, chosen to provide visitors with new and increasingly well-rounded experiences. MECSPE's efforts in the manufacturing sector's recovery will focus on three fundamental aspects: digitalization, sustainability, and training. To this end, the 19th edition of MECSPE will be full of initiatives, conferences, and opportunities to learn more about those companies whose job it is to support enterprises in the digital transition and in the development of innovative technologies that are highly competitive in the national and international markets.

“We're ready to return to MECSPE, safely and in a new exhibition centre, offering visitors a chance to become familiar with Biesse's new solutions for the machining of plastic and composite materials," states Lanfranco Fontanelli, Commercial Director for Glass, Stone, and Advanced Materials. “MECSPE is an excellent occasion to create new contacts and strengthen old ones, an event that focuses on learning about and studying the market's new trends. MECSPE undoubtedly offers all visitors a complete overview of the manufacturing industry, and we, together with our technologies, will be available to help clients create customised solutions for their factories."

BIESSE TECHNOLOGIES AT MECSPE 2021 - PAV.16 – STAND E34

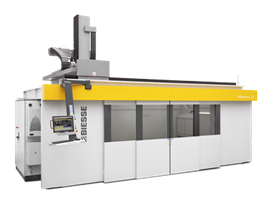

A team of experts will be present at the stand to show visitors all of the benefits and tailor-made solutions that can be developed for clients' businesses. In particular, the stand will feature the Rover Plast K FT, the new numerically controlled work centre with Biesse's Gantry structure, the most compact one on the market, designed for the machining of technological materials used in sectors like graphic arts and construction.

“At MECSPE we're presenting the new Rover Plast K FT work centre, a compact but extremely high-performance machine in terms of flexibility and ease of use, dedicated to the machining operations of plastics, alucubond, plexiglass, and much more. The work centre is extremely compact and ergonomic, given that it was designed to best fit into the manufacturing space. This gives operators completely safe access to the machine from all sides at all times and without any obstacles on the ground. We invite all of the trade show's visitors to discover the benefits offered by the new work centre, which is suitable for every machining need," states Matteo Nazionale, Product Director of Glass, Stone and Advanced Materials.

BIESSE TECHNOLOGICAL SOLUTIONS FOR PLASTIC AND COMPOSITE MATERIALS

Biesse solutions are extremely precise, easy to use, and versatile and come with all of the optional features for the machining of every material present on the market today. Biesse has created a range of products made up of panel saws (SELCO PLAST), work centres (ROVER PLAST and MATERIA), water-jet cutting systems (PRIMUS), sanders (VIET PLAST), and thermoformers (TERMA).

High speed electrospindles, high power suction systems, and cutting accessories with tangential oscillating blades provide 360° solutions to every machining need in the advanced materials sector.

"MIXED REALITY FOR ON BOARD QUALITY CONTROL OF MACHINES" CONFERENCE

Mixed reality (VR and AR) applied to various factory processes, is an example of the versatile and multidisciplinary nature of this technology. Visitors will be able to participate in a training session, scheduled for 25 November at 12pm, on mixed reality for quality control, organised with Sargomma, Orchestra, and HeadApp. The objective of the session is to demonstrate the integrated use of Industry 4.0 enabling technologies in the on-board quality control process applied to the production of small batches, always from the perspective of sustainability.

Biesse technologies for plastic and composite materials at MECSPE 2021, Pavilion 16 – Stand E34. For more information, please contact: https://www.biesse.com/ww/advanced-materials/

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil