Last years winner of the Master Joiners Best Kitchen Award, Modern Age Kitchens & Joinery understand the importance of providing clients with a quality finish to their kitchens, they also know that reducing the manual labour involved in handling sheet materials is key to a successful operation. The machinery they use in their Christchurch factory reflects these points, a Biesse Skill CNC nesting machine and a Biesse Akron 1440 edgebander, both are core to their manufacturing success.

The Biesse Skill was purchased around five years ago and was a move by the company into automatic nesting replacing as it did a single sheet router which required manual feeding and off loading. The productivity gains were immediate and substantial says Graham Woodham who runs the business with father Grant.

“You don’t make money by manually handling sheet material and the Biesse Skill has proved that to us. It has decreased our labour input and increased daily throughput in the factory while improving fi nish quality. Primary in this is its automation, it gives us the ability to lay 30 odd sheets in a stack, program it and leave it - it simply doesn’t stop cutting, little attention needed, no lifting required, no mistakes made, no injury potential. Likewise auto labelling has made a massive diff erence, a big timesaver, work automatically organised and again less potential for error.”

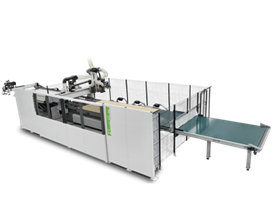

The Biesse Akron 1440 edgebander with return has similarly been a profitable capital outlay for Modern Age Kitchens, improving edge finish capabilities while reducing handling. Purchased two years ago the Akron has the latest technology with Airforce and PUR capabilities providing the quality of fi nish and invisible glue line required for clients in their sector of the market.

“Our edging now requires less handling, it is much more economical and provides a lot better finish with several significant advantage over our previous machine, not least being its near invisible glue line,” says Graham. “Requests for invisible glue lines is a first option for many clients, especially those wanting white kitchens, no one wants to be able to see dark joins in their pristine white cabinetry. The Airforce capability on the Akron means this is an easy option for us and in fact we use laser type edging with it seamless joins as a big selling point with our clients.”

“The pre-milling on the machine is also excellent giving us the best possible edge to start the process. It also has many time saving features, we have all our programs stored for easy job set up and change and all on-machine adjustment of cutters etc., can be easily and quickly done on the screen. It also has the ability to edge panel or doors with the hinge holes already in place and the return system means a lot less walking and double handling than was previously required.”

While machining capabilities were important in the selection of both machines so too was the back up and after sales service that Biesse provides.“We have had Biesse machines for some years now and they have always performed well and the after sales support has been good. It helps that Biesse have a physical presence in Christchurch, parts are usually pretty quick to arrive and they have a very good technician here as well as a very good online service.”

“Biesse training events are also helpful it is true that the best way to learn a new machine is to use it, but courses such as the recent Biesse Masterclass certainly speed that process up. We sent our operator along, he found it very good and came back with a few tips - one off which we are buying a new extra for the machine to take advantage of. These events also provide a good connection with Biesse and interaction with fellow users, we all have the same day to day issues and it’s good to see how others have solved them and also just to see what the machines are capable of outside of your own immediate use. Biesse appreciate that.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil