We simplify your manufacturing process to make the potential of any material shine.

Protecting your Investment

Capital investments in the form of machinery and equipment are necessary for manufacturing furniture and furnishing products. The productivity of those machines and equipment is essential to the success of those companies. Events that slow or interrupt the manufacturing process, or degrade the product, weaken the competitiveness of any manufacturer. One progressive company protecting their most productive Biesse investments is Luxmy Furniture, located in Punchbowl, Sydney.

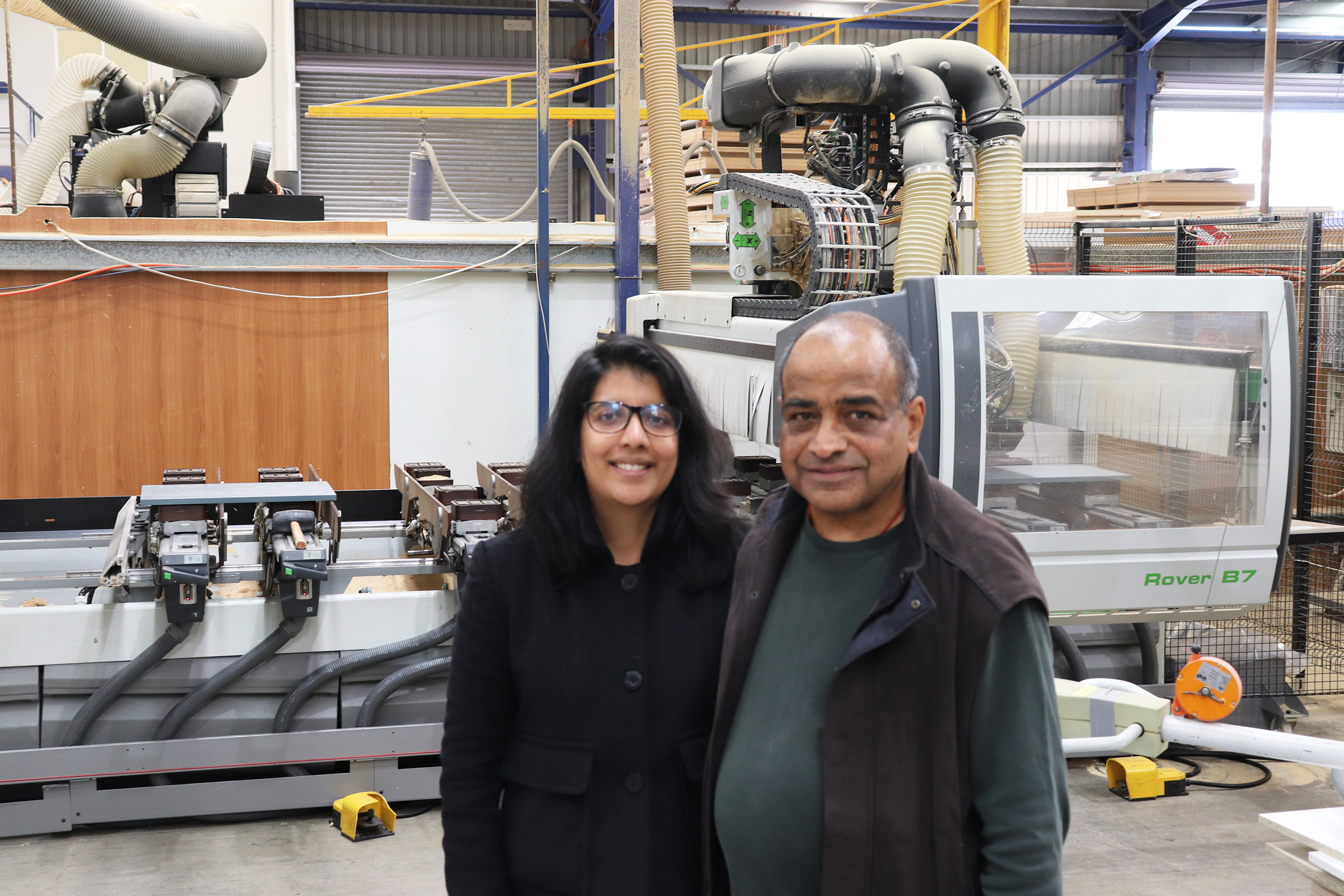

Luxmy co-operates with interior designers to produce original designs. Pooja explains, “We collaborate with our clients as early as possible to help them realize their designs to a practical solution.” Luxmy customers are commercial clients who may not have manufacturing facilities of their own or may be unable to produce certain designs. Rao, an electronics engineer says, “We are not direct to the market; we’re an independent furniture manufacturer and we produce to architectural specifications.”

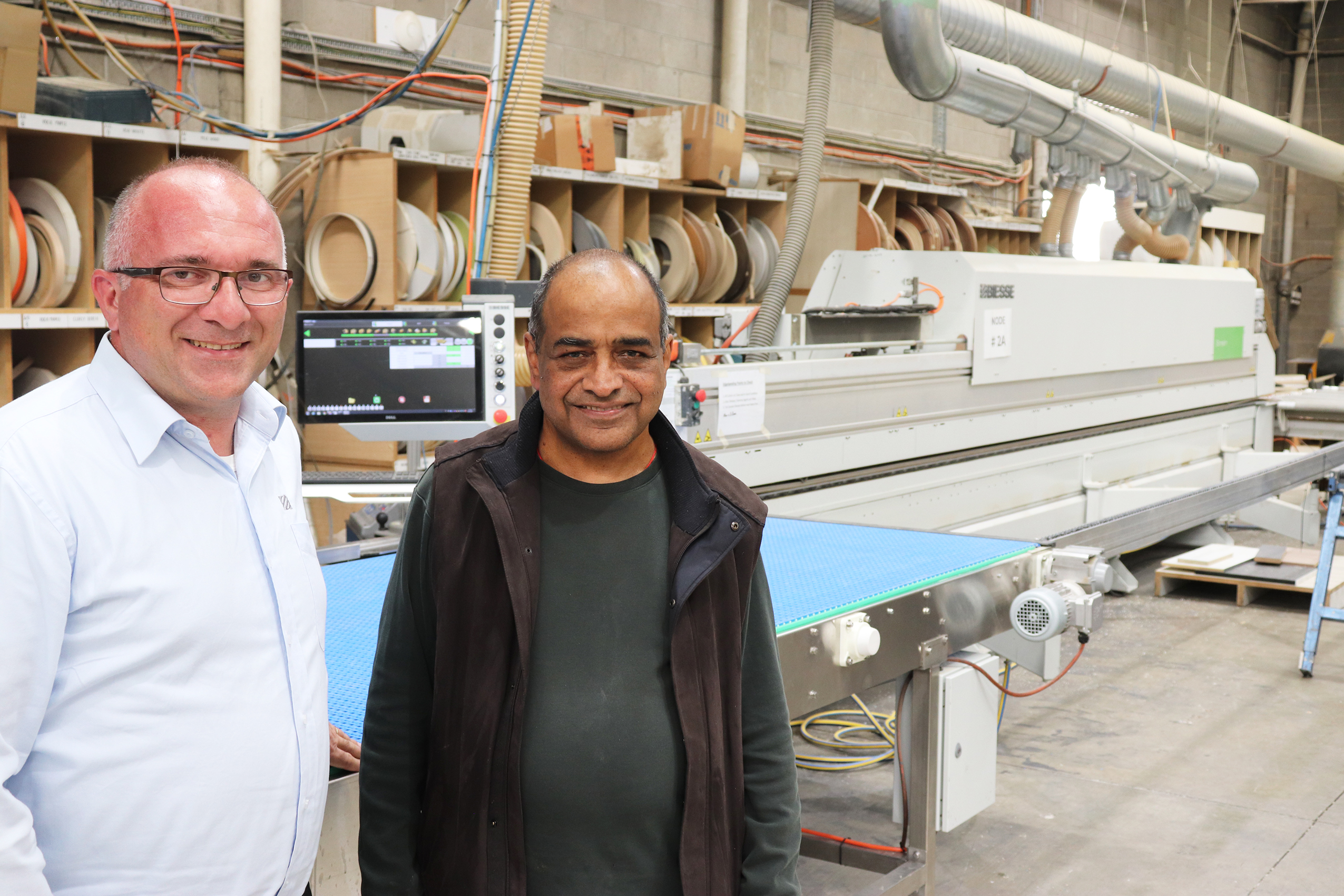

One of the most effective ways Biesse work with Luxmy Furniture is with service. Last year, Luxmy partnered with Biesse in a Preventative Maintenance Agreement of planned and scheduled servicing and maintenance. It’s a long-term strategy that will keep Luxmy’s machines not only running, but in a condition to ensure the consistency and quality of manufacturing Luxmy is renowned for. Pooja said, “For us, maintenance ensures we can maintain our capacity and supply. The best investment you can make is in yourself and to be honest, I think it’s something we should have done much earlier.”

Pooja and Rao consider regular and planned maintenance as essential to the ongoing success of Luxmy Furniture. Rao said, “We took up the maintenance agreement to guarantee reliability of the machines and of our product. But it’s not just the contract, it’s the people at Biesse we are investing in. Since Michael Bullock has come to Biesse as Australian CEO, the whole team focus to service has strengthened.” Pooja adds, “What we are concerned about is our ability to fulfill our manufacturing commitments on time and our Biesse machines are pivotal to that goal.”

With two or more machines of every type, they have a form of redundancy and protection against breakdowns, but Rao says, “They aren’t a backup, all our machines are fully worked but it is a second line of defense. Any machine from all suppliers is subject to wear and need to be maintained. Parts like bearings and sensors, and from time-to-time critical machine parts like aggregates may malfunction.” Pooja adds, “You need to think about maintenance long-term.”

Machinery and equipment maintenance involves breakdown maintenance and repair, preventive maintenance, and predictive maintenance. Breakdown maintenance and repair is the after-the-fact restoration of failed equipment. In this case your machinery stops and so does your production. Preventive maintenance is the systematic servicing of equipment to reduce the possibility of failure. Predictive maintenance involves the use of computer software to detect conditions that might eventually lead to equipment failure. Biesse machines connected to Sophia software IoT platform has an increasing capacity to detect wear and tear and reduce the incidence of future breakdowns.

But it’s in the area of preventive maintenance that there is the most benefit for the manufacturer. The Biesse machines at Luxmy Furniture are now all covered by a maintenance agreement of planned and scheduled servicing where Pooja says, “Biesse takes full accountability for the ongoing performance of our machines. The service agreement is an extension of our partnership with Biesse.”

“The biggest benefit for us at Luxmy Furniture is that it increases the reliability of our machinery and solidifies our relationship with Biesse, our machine supplier. Regular servicing allows us to produce a high-quality product with less lead times. We think of servicing production machinery like we think of servicing a car. There is a predictable cost in doing this but also a predictable outcome where the car lasts longer, has a higher resale value and performs exactly when you need it to.” The agreement with Biesse is about scheduled visits plus other visits by Biesse tech’s, usually at a time that suits Luxmy.

In any manufacturing environment, some output is inevitably lost because of breakdowns, reactive maintenance, and operational inefficiencies. Scheduled servicing reduces all of these incidents and provides the manufacturer with the best possible outcome in terms of their commitments to their customers. Scheduled maintenance has a positive effect on the three key elements of competitiveness: quality, cost, and product lead time. Well-maintained machines hold tolerances better, reduce scrap and rework, and raise part consistency and quality. By increasing uptime and yields of good parts, scheduled and planned maintenance can reduce capital requirements and cut total production costs.

Pooja said, “Our Biesse machines are extremely agile; our client’s demands are changing so we must change as well. For us, we need to produce a better, higher-quality product with lower lead times. We’re building a culture of quality and happiness at Luxmy. We re-invest our money in people and technology to make our workplace better and more productive. Regular, scheduled maintenance and servicing is one more element in our culture that allows our Biesse machines to be more capable of meeting all the challenges our customers throw at us.”

You need to think about maintenance long-term.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil