Luxmy Furniture and Biesse; trust, loyalty and integrity.

Sudhindra Rao arrived in Australia from Mumbai in 1992 with his wife; two children; four suitcases and a little money to buy a house. They also brought a willingness to work hard; to give something back to their new country. Theirs is an Australian story we can all relate to, a story of risk for reward but also of adventure; moving everything to a new country for the opportunities Australia offered. And they found it in Sydney with the furniture industry and a 20-year partnership with Biesse Australia.

Sudhindra prefers to be called Rao; it’s easier for his customers he says. He’s been joined by his daughter Pooja around five years ago and together with a loyal team who have been with the company for up to twenty years; manage Luxmy Furniture in Punchbowl, Sydney. Luxmy is derived from Lakshmi; the Indian Goddess of wealth, abundance and prosperity. She is often depicted with four hands representing the four goals of Hindu human life. Pooja explains “We’re not about just making money; we’re building a culture of quality and happiness here. We re-invest our money in people and technology to make our workplace better and more productive.”

It’s been quite a journey since they first arrived in Australia some twenty-five years ago but it didn’t take Rao long to get started. An electronics engineer in India, he’d had his own businesses there including an electroplating plant. He brought his manufacturing and management expertise to his work in Australia. Starting out here in a recession, he took on labouring work but soon got a job managing a powder coating company. Making this company profitable with modern manufacturing principles, he was quickly made General Manager.

Rao quickly realised that he could operate a powder coating business himself so he went out on his own. Many of his customers at the time were furniture companies and there was a big demand for powder coated frames. One particular customer was Herman Miller. Their furniture was then only made in Michigan in the USA and the lead time for table tops was too long. They suggested to Rao that he could make the tops in Australia and so another business opportunity opened up. Rao recalls “Our powder coating business was doing well but it was still a risk.” He bought a Laminex factory in Sutherland for a peppercorn payment and every Thursday, went to Herman Miller for training. “There was a lot of pressure to be successful early,” Pooja said. “We bought the factory with a Biesse machine already there and this was the start of our long partnership with them.”

Luxmy produces table systems; chairs; lounges; office screens; ottomans; commercial furniture and joinery and will co-operate with interior designers to produce original designs. Their customers are commercial clients who may not have manufacturing facilities of their own or who may not be able to produce certain designs. Rao says “We are not direct to the market; we’re an independent furniture manufacturer and we manufacture for the corporate market only.” Pooja adds, “We’ve tried to make our business model as simple as possible and cut out many of the overheads. We don’t employ engineers so Biesse has to work for us. When you have a partner that looks after you, everything is simpler. Biesse listen to what we want and customise their machines accordingly; their World-wide experience is very important to us.”

Creative Director Simon Murgatroyd said “Our Biesse’s are the beating heart of the company; they feed the factory. We make tops for all the major commercial players; the icons of Australian commerce. Most of our work is customised by the consumer. Our machinery needs to be flexible and reliable and over twenty years they’ve never let us down.” Pooja adds “Our Biesse machines are extremely agile; our client’s demands are changing so we must change as well. Small orders are more common these days and we have to make it easy to meet the clients lead time. The Biesse machines allow us to meet all the challenges our customers throw at us.”

“We work very closely with designers,” Pooja explains. Rao recalls “One of my first jobs in Australia was making belt buckles. I went round to the fashion houses where I met many young Australian designers like Lisa Ho. I learnt that design was an important part of manufacturing.” While some Australian companies are obsessed with overseas designers, at Luxmy they support local talent. Pooja says, “Designer product takes twelve weeks to come from Italy; eight weeks from China but less than five weeks from us. Designers spend a lot of time with the product design and often don’t leave enough for manufacturing. That’s where we have to be flexible and fast. We collaborate with our clients as early as possible to help them realise their designs to a practical solution. We’re partners more than suppliers and we look at Biesse exactly the same way; Biesse are true partners and treat us like we treat our own clients.”

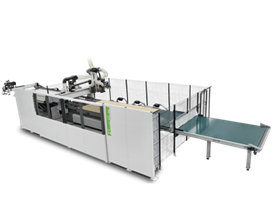

Over the years Luxmy have added a number of Biesse machines and now run two beam saws; two edge banders and five CNC routers including a five axis machine with on-board edge banding. Biesse provide Luxmy with the capacity to apply edges with high-performance PUR glue that leaves a perfect edge with an almost invisible glue line. Quality is a high priority but performance of a commercial product is also extremely important. Pooja says “Biesse understand our business; they talk to us and supply us with the machines we need to do our job properly.” Rao adds “Every five to seven years technology takes another step so that’s when we look to upgrade our machines. I can tell you that our five-axis Biesse has changed the direction of our business and opened up markets for new products.”

Luxmy sees themselves as the industry’s manufacturer and work like a retailer’s factory if they had one. They supply top to middle of the market and are pleased to say that much of Sydney’s CBD would have their furniture. They produce furniture for universities; banks; government and commercial projects and are green star; eco-sustainable; ISO14001 certified and have an AFS chain of custody (forest) certification. “Our investments are in our employees and in our Biesse machinery. Biesse work with us; they understand what we do and how we work, they understand what’s important to us. Over the last six years or so the commercial office structure has changed. We used to make lots of workstations but office work is different now. It’s all about ‘hot desking’ and agile workspaces and we’ve had to change how we do business” said Pooja. “We make everything to architectural specifications; even one-off product. It’s a credit to Biesse that they’ve seen our manufacture change from mass production to niche customisation and have adapted their machines to suit our needs,” she says.

Rao tells us “Our Biesse machines haven’t reduced our staff levels; it’s not what we were looking for. They have lifted our production capacity and added to our flexibility and our ability to do complex work. The Biesse also replicates traditional handcrafts consistently; we don’t see this as losing skills but allowing our trained employees to do higher level skilled work using the high-end capabilities of the Biesse product. The machines have led to job security.” Pooja adds “Twenty years ago we just cut up board but now we’re product-focussed thanks to our Biesse machines.” Rao adds, “It’s a cliché, but we are able to work at the ‘cutting-edge’ with Biesse.”

Back in 1992 Rao looked at the US; Canada and Australia to settle his family. As he puts it “In Australia the systems are very similar to India; there’s the warm climate; you drive on the same side of the road and you also play cricket so for us Australia was very attractive.” The Americas’ loss is Australia’s gain and Rao went on to create a real Australian story with Luxmy Furniture. The story isn’t over just yet as Rao and Pooja move forward to continue a brand built on close communication; trust; loyalty and integrity; a brand built on people and technology; technology provided by their trusted 20-year Biesse partner.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil