Personalisation in real time

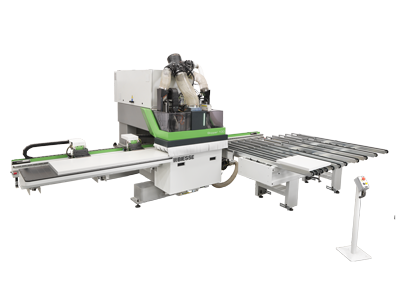

Skipper 130 is an NC processing center that allows the processing and boring of panels of completely different formats in sequence, and without interruptions. It's ideal for the nonstandard production of large companies, for producing small batches for third parties, and for those requiring just-in-time flexible production.

+

Complete flexibility for machining panels of different thicknesses and sizes. Simultaneous, continuous machining operations on both the upper part and the lower part, without the need to feed the panels through the machine several times.

+

The piece size measuring system verifies the exact thickness of the panels in real time, automatically adjusting the machining depth as necessary.

+

An extremely powerful yet user-friendly operator interface that allows quick decisions and automatically optimises the cycle on the basis of the tools available, to minimise work times.

Processing of different shapes in sequence

Skipper 130 is revolutionary. It can machine all 6 panel faces simultaneously in one single step (including dowel insertion).

Immediate productivity

Long term reliability and precision. Material transformation cost reduction of over 60%. Maximum yield for batch 1 production. Easy use for everyone.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil